The number of car thefts increased tremendously in these years. One of the best ways to deter automobile thieves is to learn how to wire an electric fuel pump to a toggle switch. If you use this simple system, your fuel pump will be shut off, making it impossible for someone to steal your car. So, How To Wire A Fuel Pump To A Toggle Switch?

The toggle switch allows you to easily control your fuel pump’s operation with just a switch flip. The fuel system of your vehicle is not only more secure and safe due to this feature, but it also provides added convenience. Our fuel pump toggle switch wiring guide is your one-stop shop for convenient and effective fuel pump wiring.

Read the article to learn more about How To Wire A Fuel Pump To A Toggle Switch.

What is a Toggle Switch?

A toggle switch operates by pushing a lever up and down or left and right to switch an electrical circuit. The toggle is a small wooden rod that replaces buttons as a clothing fastener. Due to the resemblance between the switch lever and the toggle used in clothing, the term “toggle switch” was coined.

What are the Types of Toggle Switch?

There are four types of these switches, each with a different combination of poles and throws, such as SPDT, SPST, DPDT, and DPST. A switch’s poles are typically the individual power supplies, whereas its throws are the different locations the switch can control, such as ON and OFF.

1. SPST Toggle Switch

An SPST is a “Single Pole Single Throw” circuit, which includes two terminals, like input and output. Switches like these work like simple ON/OFF switches. In a single branch circuit, this switch makes or breaks a connection between two conductors.

By opening this switch, the circuit will be disconnected, preventing current from flowing through the load. When the switch is closed, current flows throughout the load.

2. SPDT Toggle Switch

A SPDT toggle switch is one that can make or break a connection between two single conductors. SPDT stands for “Single Pole Double Throw”. There are usually three terminals on these types of switches, which are generally used in pairs.

3. DPST Toggle Switch

The DPST switch is used to make or break the connection between two circuit conductors within one branch circuit. DPST stands for double-pile single throw. In general, these switches include four terminals that can be used to connect or disconnect two pairs of terminals at the same time.

4. DPDT Toggle Switch

A DPDT toggle switch is a toggle switch that makes or breaks the connection between two conductors to two separate circuits. The term DPDT stands for double pole double throw. Three and four of these switches are powered, while the remaining terminals, like 1, 5, 2, and 6, are driven by the remaining terminals. Four-way switches are also known as four-position switches.

5. LED Toggle Switch

A LED is usually mounted on the tip of these toggle switches. In this LED, the switch condition is mainly indicated, such as ON/OFF. In handheld devices, as well as front-panel interfaces, these switches are used.

6. Mini Toggle Switch

Switch with mini toggle available in smaller sizes which are also called snap-action switches or micros switches. Switches with spring-loaded toggles respond to some force applied to them. Through current inflow, the switch’s spring activates & shifts the contacts into place. As well as being used in domestic and industrial equipment, these switches are designed to be used extensively in a wide range of applications.

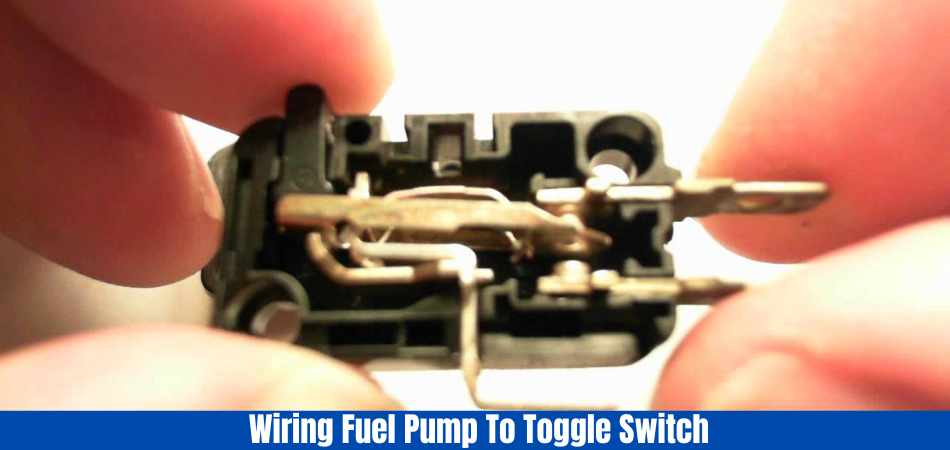

What is the Structure of a Toggle Switch?

Construction

As parts of a toggle switch, levers, springs, o-rings, plungers, moving armatures, cases, and bases can be used.

Lever

The lever is available on top of a switch which is used to control the circuit by turning ON & OFF. In general, these are made of resin, though metal can be used on larger items for extra strength.

Spring

A spring loaded within the lever of the switch. There is always a contact between the lever and the base due to this spring pushing outwards on the lever.

O-ring

There is a circular rubber ring in the switch that seals the connections between the case, base, and moving parts.

Plunger

An electrical switch’s plunger is a resin component attached to the lever’s base. Lever movement can limited by having the lever in contact with the bottom of the base at all times.

Moving Armature

The lever’s moving armature consists of a U-shaped contact. In order to turn on the condition of the switch mechanism, the wire terminal positioned in between the tips of the contact that moves through the lever.

Case

By having a hole on the upper surface, the case provides support to the lever and protects the internal components of the switch.

Base

To protect the inside components of the switch, the base used with the case. From the bottom of the base, the switch terminals protrude.

What is the Major Function of A Toggle Switch?

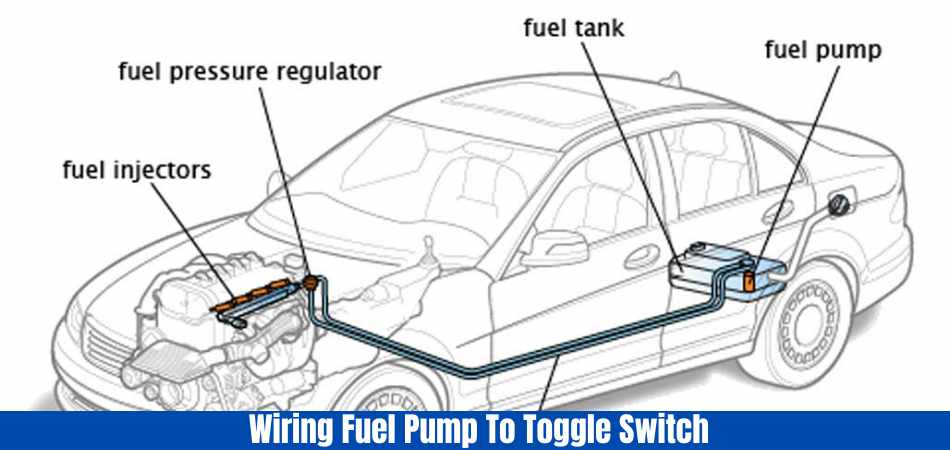

For a fuel pump to work, a toggle switch is crucial. Fuel pump activation and deactivation are conveniently and reliably accomplished with this small yet powerful device.

The toggle switch acts as an intermediary between the power source and the fuel pump when it comes to fuel pump functionality. It enables the fuel pump to deliver fuel to the engine by allowing electrical current to flow through the switch.

For vehicles and machinery that rely on fuel pumps, toggle switches serve as an essential safety feature. The fuel pump can effectively shut down during emergencies or routine maintenance by tripping the switch.

Moreover, toggle switches are durable and easy to operate. Users can quickly turn them on or off with a quick movement thanks to their simple mechanism. As a result, they are handy for controlling various functions within vehicles and equipment.

Fuel pumps controlled by toggle switches, which act as essential control components. Providing efficient fuel delivery is an essential part of any system due to its reliability, convenience, and safety features.

What are the Tools Required To Wire A Fuel Pump To A Toggle Switch?

- Single post relay

- Inline fuse

- Digital Multimeter

- Wire strippers

- A kill switch kit

Tip: Hide your kill switch to prevent your fuel pump from being stolen by auto thieves.

How To Wire A Fuel Pump To A Toggle Switch? Step-By-Step Guide!

Generally, here’s how you wire a toggle switch to a fuel pump:

- Find and access the components and wiring of your fuel pump. Fuel pumps should be checked for power.

- The fuel pump cutoff switch should be connected to the fuel pump.

- You should cut and splice the fuel pump wire. When necessary, your kill switch cuts electricity to your pump to protect your car wiring.

The steps for wiring an electric fuel pump to a toggle switch are fairly straightforward, and we will explain them below.

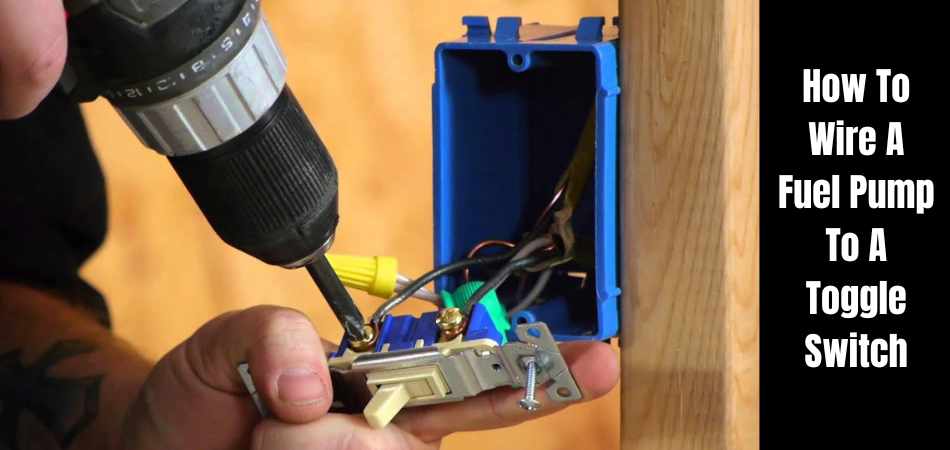

Step 1: Find your fuel pump and access it

Locate the electric fuel pump on your vehicle. You are most likely to find it in your fuel tank. Remove the filler cap from the fuel tank and place your ear near the nozzle. It is essential that someone turns the ignition key from the off position to the power position.

It takes two or three seconds for the gasoline pump to click or buzz after it is turned on. You can find the pump by tracing the fuel line from the tank to the engine if you are sure it isn’t inside the tank.

Make sure you can access your fuel pump component and wiring. Your fuel pump may need to be accessed through your trunk or dismantled, depending on your application. No matter how you get to the gasoline pump assembly, it doesn’t matter.

The connector needs to be accessible; then, the connections must be stripped and cut.

Step 2: Check the fuel pump’s power

Your digital multimeter should be used to check the voltage. Check for switched current by grounding the black lead of your multimeter after unplugging the fuel pump harness. For this to work, your ignition must be turned on.

Check if the cables can be routed through the floor of the car to the outside. In case a hole needs to be drilled, drill it. Ensure that there is enough space underneath the switch assembly for the wiring and switch assembly.

Step 3: Connect your fuel pump kill switch

The switch should be installed in the desired location. Install the switch from the back and tighten the ring nut on the outer side of the switch body. On and off positions should be oriented correctly; for example, up is on, and down is off.

When you have purchased a complete kill switch kit, this phase is simple and uncomplicated. By following the circuit diagram for the fuel pump kill switch shown below, you can connect your fuel pump kill switch using a common single post automotive relay.

In the above figure, you can see how to modify a standard automobile relay to serve as a fuel pump kill switch. Upon completion of the installation of your kill switch, you will be able to turn off your gasoline pump at any time.

You can then hide or stash the gasoline pump kill switch so that thieves cannot find it.

Step 4: Turn off your fuel pump’s power line

The fuel pump components should trimmed and spliced according to the wiring diagram above. The single post relay and kill switch protect your car wiring and shut off the electricity to your pump when you need them to.

Make sure your wiring checked after installing your fuel pump kill switch to prevent your pump from turning off by itself.

It is highly recommended that you solder your connections, even though you can use fast electrical connectors.

When installing a gasoline pump kill switch, never access the fuel pump component. It can hazardous to work in an environment that is filled with gas vapors or fumes.

Learn more about it here.

4 Essential Tips To Wire A Fuel Pump To A Toggle Switch

There are a few crucial considerations to keep in mind when implementing this anti-theft strategy. The following are just a few of them:

Tip 1: Keep a relay handy at all times

Installing a kill switch and leaving it alone not recommended. There are many three-prong toggle switches that lack the necessary amp capacity, resulting in electrical problems.

It is possible for these issues to cause your switch to melt or even catch fire. Always use an automotive relay and a kill switch that appropriately rated rather than taking chances.

Tip 2: Put an inline fuse in place

In case of an electrical disaster, an inline fuse is crucial for keeping your power cable safe.

Tip 3: Choose the right wire gauge

Make sure the automotive wire is strong enough to handle the voltage. A thinner wire might be unable to transmit voltage securely, resulting in an electrical fire.

Tip 4: Hide your fuel pump kill switch

In the event that the kill switch placed in an easily accessible location, your installation will be rendered useless. Your switch should mounted or hidden somewhere safe and only accessible to you.

What are the Advantages of Wiring A Fuel Pump To A Toggle Switch?

A toggle switch can used to connect a fuel pump to a number of benefits and advantages. Toggle switches allow you to control the fuel pump’s operation, allowing you to turn it on and off as needed.

During maintenance or troubleshooting, this is particularly useful for controlling fuel flow directly.

You can also add an additional layer of security to your fuel pump by installing a toggle switch. A manual switch that disables the fuel pump allows you to prevent unauthorized use or theft of your vehicle.

It is also possible to wire a fuel pump to a toggle switch at a fairly low cost. The cost of replacing faulty or malfunctioning factory switches may be high or require complex repairs in some cases. Toggle switches can eliminate these issues and provide you with an easy-to-use alternative.

In order to ensure the safety of any electrical component in your vehicle, it is important to take the proper precautions and to consult professional guidance. By ensuring that the wiring performed correctly and safely, any potential hazards or damages can be avoided.

The toggle switch provides convenience, security, and cost-effectiveness when wiring your fuel pump. The device gives you direct control over fuel flow while adding an extra layer of protection to your vehicle.

What are the Disadvantages of Wiring A Fuel Pump To A Toggle Switch?

Fuel pumps can be wired to toggle switches, but there are several disadvantages to consider.

The first disadvantage is that you eliminate essential safety features that have been introduced into the vehicle’s electrical system. when you bypass the original wiring system and connect the fuel pump directly to the toggle switch. Fuse and circuit breakers are safety features that prevent electrical malfunctions and fires.

Additionally, wiring a fuel pump to a toggle switch increases the risk of accidental fuel leakage or ignition. For optimal engine performance and safety, the original wiring system ensures proper fuel flow and pressure regulation.

You can inadvertently damage the engine or create dangerous situations by circumventing this system.

In addition, if you use a toggle switch instead of the ignition switch or key, you remove an additional layer of security. By accessing the toggle switch, anyone could start or stop the fuel pump without authorization.

In addition, you may lose any warranty or insurance coverage you have if you modify your vehicle’s electrical system in this way. Any modifications to your vehicle that could impact its safety or functionality should be discussed with a professional mechanic or automotive electrician.

Despite the convenience of wiring a fuel pump directly to a toggle switch, there are potential disadvantages and risks associated with this practice. When working with automotive electrical systems, safety should always be the top priority.

What are the Precautions of Wiring A Fuel Pump To A Toggle Switch?

It is essential to take several precautions when wiring a fuel pump to a toggle switch. Working with any electrical component, especially those related to fuel systems, should always be done safely.

To begin with, make sure that the toggle switch rated for the fuel pump’s voltage and current requirements. Short circuits, overheating, or fire can result from an undersized or incompatible switch.

It is also essential to follow proper wiring techniques. In addition to using the correct gauge of wire, it is important to ensure that all connections are secure and insulated. Electrical malfunctions or hazards may occur if exposed wires or loose connections are present.

In addition, the toggle switch and fuel pump wiring must protected by a fuse or circuit breaker. Components will be protected against overcurrent situations, and damage will be prevented.

Lastly, when it comes to such wiring tasks, it is highly recommended to consult with a professional or experienced individual. Depending on the make and model of your vehicle, they can provide advice on following all safety protocols.

By following these precautions, you will minimize the threat of electrical faults and ensure your vehicle’s fuel system runs safely.

Conclusion

Safety should always be a top priority. Make sure to disconnect the vehicle’s battery, carefully follow all instructions, use the appropriate tools and components, and, if in doubt, seek professional help. Fuel pump safety and reliability depend on the correct installation and operation of the toggle switch.

You should also consider any legal requirements or regulations applicable to your region when modifying your vehicle’s fuel pump wiring. It is essential to comply with local laws and regulations in order to avoid any legal issues. Using the correct knowledge, safety measures, and legal standards, you can confidently perform this modification and enjoy the benefits of a manually controlled fuel pump.

Read more of our articles here.

FAQs

Can a fuel pump be wired to a toggle switch safely?

The quality of the wiring determines the safety of the installation. Following safety guidelines and doing it correctly can make it safe. Nevertheless, improper wiring can be dangerous. Follow safety precautions and understand the process.

Are there any special tools or equipment I need to wire a fuel pump to a toggle switch?

Wire strippers, crimping tools, electrical tape, and a toggle switch are all basic electrical tools you’ll need. A wiring diagram your specific vehicle may also be required.

Is it possible to install a toggle switch for my fuel pump in any vehicle?

It is possible to install a toggle switch for the fuel pump on most vehicles. It’s important to consult your vehicle’s service manual or seek professional assistance if you are unsure about the wiring and where the fuel pump is located.

Can you tell me what type of toggle switch I should use?

Toggle switches designed for automotive applications should be high-quality. Make sure it can handle the electrical load of the fuel pump and has an appropriate amperage and voltage rating.

What is the best place to install the toggle switch?

Toggle switches should be installed in a location that is easily accessible but not prone to accidental activation. In addition, it should mounted securely and in a way that does not interfere with the vehicle’s operation.

Leave a Reply