Your car’s brakes should respond quickly and effectively when you press the brake pedal to stop or slow down. If your car has an Anti-Lock Braking System (ABS), you may sometimes notice that the brake pedal goes to the floor or feels mushy. Having difficulty controlling the vehicle can be alarming and dangerous, as it can make it harder for you to avoid collisions. But Can Abs Cause Brake Pedal To Go To The Floor?

A sinking brake pedal is an extra cause for concern, considering the potential consequences of any brake problem. It is imperative to dive in and solve the issue before continuing to drive with brakes you are unsure of.

In this article, you’ll learn the four most common reasons why your brake pedal goes to the floor, along with some helpful tips. Further, we will also discuss Can Abs Cause Brake Pedal To Go To The Floor?

It’s time to get started, so let’s begin.

How Do Brakes Work?

You can prevent brake failure by understanding how your brakes work:

- By pressing on the brake pedal, you create a mechanical force that is amplified by the brake booster.

- In this case, the hydraulic pressure is converted from mechanical force to hydraulic pressure by the master cylinder.

- Your master brake cylinder then presses hydraulic brake fluid into your brake lines and hoses, which carry it to the wheels.

- As the brake fluid pressure increases, the caliper piston presses the brake pads against the brake rotors.

- In drum brake vehicles (usually the rear brake), the brake shoes, rather than pads, are pressed against the brake drum by a wheel cylinder.

What is ABS?

An Your car’s anti-lock brake system (ABS) prevents the wheels from locking up when you brake. The result can be a loss of steering control and a longer stopping distance.

Using sensors that monitor wheel speed and other factors, ABS modulates brake pressure independently for each wheel. There are valves, an electric control unit, a pump, and wheel speed sensors in this unit. Learn more at here.

How Does ABS Work?

A car without ABS experiences friction when the brake pads squeeze against the rotors, slowing down the wheels. Overbraking or braking on a slippery surface can lock up the wheels, which means they stop rotating.

As a result, the car may skid and lose control, potentially resulting in an accident. By using a computer-controlled hydraulic system to adjust the brake pressure for each wheel, ABS prevents wheels from locking up.

When a wheel slows down too rapidly, ABS reduces the brake pressure on that wheel. Skidding is reduced because the wheel continues to rotate, allowing steering control to be maintained.

What are the Benefits of ABS?

Among the benefits of ABS in braking systems and vehicles are:

1. Performance Improvements in Braking

With ABS, the driver is able to stop the vehicle more quickly and safely, reducing the stopping distance.

2. Stability enhancements for vehicles

When driving on wet or slippery roads, ABS helps the driver maintain control of the vehicle.

3. Confidence increased among drivers

The driver gains more confidence and reduces the risk of an accident with ABS, as it provides a more predictable and stable braking experience.

4. Wear and tear on tires reduced

The tires may last longer because ABS prevents the wheels from locking up and reduces skidding and sliding.

5. Improved steering control

ABS allows the driver to maintain steering control of the vehicle during hard braking, essential for avoiding obstacles.

6. An overall improvement in safety

Having ABS on your vehicle can help prevent accidents and reduce the severity of injuries in the event of a collision. Most countries now require ABS on all new vehicles.

What are the Symptoms of Brake Pedal Going to the Floor?

The following symptoms can occur when the brake pedal pressed to the floor:

1. A spongy or soft brake pedal:

Air in the brake lines can cause the brake pedal to feel soft or spongy when you press down on it. It can also be a leaking brake fluid or worn brake pads.

2. Light on the brakes:

In the event that you see a brake warning light on your dashboard, this may indicate that there is a problem with your brakes.

3. The brakes are not responding:

Whenever you press down on the brake pedal, your car does not slow down or stop as expected, this is a very dangerous situation. Your brakes may be having a serious problem if this happens.

Other Signs of Brake Trouble

Besides these problems, you may also notice other signs of brake problems that require immediate attention. A car with brake problems is never a good idea to drive. Any problem with your brake system could prevent you from stopping your vehicle. There are also other signs of brake trouble, such as-

- An ABS or brake warning light on the dashboard

- Noises such as grinding, scraping, or squealing

- A burning chemical smell or a smell coming from the carpet

- Whenever you brake, you pull to one side

- If you brake, you may feel a vibration or wobble

- The brakes are emitting smoke

When your brakes squeal, they’re overheating and on the verge of failure. You should pull over your vehicle immediately if you suspect your brakes are too hot.

Can Abs Cause Brake Pedal To Go To The Floor?

Can Abs Cause Brake Pedal To Go To The Floor? ABS does not directly affect how far your brake pedal goes to the ground. It prevents the brake pedal from going to the floor instead. Further, it releases brake pressure when it detects a wheel is about to lock up, which prevents the pedal from going to the floor.

There is, however, a possibility that a malfunction in the ABS can cause the brake pedal to go down. Having a malfunctioning ABS module or hydraulic control unit can result in your brake pedal feeling spongy or soft or even going all the way down.

What Causes the Brake Pedal Going to the Floor?

In most cases, a brake pedal that goes to the floor caused by a leak in the brake system, either externally or internally. Besides the master cylinder, brake calipers, and brake lines, external leaks can occur anywhere in the system. There is likely a problem with the master cylinder if there is an internal leak. Can Abs Cause Brake Pedal To Go To The Floor? Yes, it can.

In addition to these reasons, there are other possible causes as well. Here is a comprehensive list that includes a few tips on solutions as well. The brake pedal can go to the floor for several reasons. Here are some solutions to these problems.

1. The brake lines contain air

Brake pedal force transferred to brake calipers by hydraulic pressure in your car. Having air in the brake lines can prevent the hydraulic pressure from building up, causing the brake pedal to go all the way down.

Solutions

Breathing your brakes will remove any air that may be present in the lines.

2. Leak in brake fluid

Leaking brake fluid is another potential cause of a brake pedal going to the ground. Whenever there is a leak in the brake lines or any of the brake components, you lose a lot of brake fluid and your brake pedal will feel spongy.

Solutions

- The first step is to locate the leak’s source. The brake line may damaged, the caliper or wheel cylinder may be leaking, or the brake hose might torn.

- Secondly, replace the damaged component or repair the leak, and then bleed the brakes to remove any air.

3. Damaged brake pads

It is possible for your car’s brake pads to wear down, resulting in a spongy or soft brake pedal. As a result of worn brake pads, the brake pedal may go right to the floor if there is not enough friction.

Solutions

- Step 1. If the brake pads are worn, replace them.

- Step 2. Check the brake calipers to ensure they are working properly.

4. A defective master cylinder

In the brake system, the master cylinder is responsible for generating the hydraulic pressure that is needed to stop the car. Having a faulty master cylinder or a worn one can result in the brake pedal going down to the floor.

Solutions

- Ensure that the master cylinder replaced with a new one. The 788 inch bore master cylinder is our pick.

- Below is a video that will show you how to fix a sinking brake pedal.

How Can ABS Affect Brake Pedal Feel and Performance?

It is true that ABS can enhance braking performance in many situations. But it can also introduce some challenges that affect the feel and performance of the brake pedal. When air trapped in the brake lines or when the ABS module malfunctions, the brake pedal can feel spongy or low. A spongy brake pedal indicates that there is a delay in building up pressure in the brake system, resulting in reduced stopping power and driver confidence.

When the ABS module fails to activate or modulate the brake pressure properly, a long stopping distance or increased pedal travel may result. Many factors can contribute to this, including a faulty wheel speed sensor, damaged brake lines, worn brake pads or rotors, or a malfunctioning ABS pump or solenoid. A problem with the ABS system may indicated by the ABS warning light on the dashboard.

When Should You take Your Car in for Repair?

It’s always a good idea to have your car repaired as soon as possible if your brake pedal goes all the way down.

As your foot presses your foot onto the brake pedal, the brake fluid transfers the pressure from the pedal to the calipers, which squeeze the brakes.

In order to ensure the safety of yourself, your passengers, and other road users, you should investigate the problem right away. Basically, putting off this task until it’s too late is not a good idea!

Nevertheless, you can do it yourself if you wish. However, someone unfamiliar with brakes should not attempt this, as incorrect work can worsen the situation. You should seek professional assistance if you feel uncomfortable doing this yourself.

Can You Drive When the Brake Pedal Goes to the Floor?

You should never drive a vehicle that has a brake pedal that sinks to the floor or has difficulty achieving pressure. There is a serious brake problem here that needs to addressed and repaired as soon as possible. It would be highly dangerous to neglect doing so and pose severe safety risks.

What Should You Do If Your Brake Pedal Goes to the Floor While Driving?

Pull over as soon as possible and stop applying gas. When you are in an emergency situation, do not simply yank on the brakes.

You should downshift to use engine braking and apply your emergency brake only after you have completely stopped. You should then contact a towing company or mobile mechanic to inspect and repair your vehicle.

The risk of injury to yourself and others is too high if you continue driving if you are experiencing brake problems. Moreover, you probably won’t be able to get insurance coverage if you are negligent.

Let’s examine how your brake system works in more detail since we briefly discussed brakes.

How Much Will this Cost to Get It Fixed?

In general, a broken brake pedal can cost anywhere from $100 to $600, depending on the extent of the damage and the type of car. It is recommended, however, that you have a qualified mechanic evaluate the problem for an accurate estimate.

Therefore, it’s difficult to determine which cause would cost the most to fix. You’re probably looking at about $200 to £300 if there is brake fluid leakage from the caliper, rubber lines, or rusted brake lines.

The brake master cylinder needs to replaced, and you don’t want to go with the cheapest one. As a result, you can expect to spend about $100 to $150 for labor and $150 to $250 for the part itself.

In this case, you would only have to pay for the work of aligning the brake shoes, which could cost up to $150. The cost could quickly rise to a few hundred dollars if the brakes damaged.

Keeping in mind that these are only estimates, and the final cost can vary depending on many factors, such as location, quality of parts, and who performs the work.

What are the best ways to take care of the ABS in your car?

Keeping your anti-lock braking system (ABS) in good working order is essential for safe and efficient braking. The following tips and steps will help you maintain your ABS:

1. Performing regular inspections:

Keep an eye on the ABS warning light on your dashboard periodically. The system may be malfunctioning if it remains illuminated. You should have it checked by a professional.

2. Fluid for brakes:

Your car’s brake fluid should be at the recommended level and in good condition. It is common for brake fluid to absorb moisture over time, which can affect the performance of the ABS system. Your car’s owner’s manual should tell you how to replace the brake fluid.

3. Maintenance of tires:

Ensure that your tires are properly inflated and that their tread depth is adequate by keeping them at the recommended pressure. To function correctly, ABS relies on wheel speed sensors, so tire condition is vital.

4. Maintain clean sensors:

It is essential that the ABS system has wheel speed sensors. Make sure they are clean and free of debris and corrosion. If necessary, gently clean them with a soft brush or cloth.

5. Inspection of brake pads and rotors:

Keep your brake pads and rotors in good condition by inspecting them regularly. It is possible for worn brake components to affect ABS performance. Brake pads and rotors should replaced as needed.

6. Diagnostic scans for ABS:

When your ABS warning light comes on, have it checked by a qualified mechanic who has diagnostic equipment. To pinpoint the problem, they can retrieve error codes from the ABS control module.

7. Brake softly:

If possible, avoid slamming on the brakes. It designed to prevent wheel lockup during hard braking, but excessive use can damage the system.

8. Be cautious when driving:

To avoid activating the ABS, drive safely and maintain a safe following distance.

Final Thoughts: Can Abs Cause Brake Pedal To Go To The Floor

Now you have some idea on Can Abs Cause Brake Pedal To Go To The Floor. It’s a nightmare to find your brakes without hydraulic pressure. When this happens, you will usually be able to figure out the cause if you know the most common causes. Despite the fact that you might need a professional to fix it, it isn’t a major repair. The cost shouldn’t be anything more than a necessary expense considering the consequences.

Read more of our articles here.

FAQs

How does ABS work in a vehicle?

ABS is an acronym for Anti-lock Braking System. During hard braking, this safety feature prevents wheel lock-up. While braking, ABS modulates brake pressure to each wheel independently to maintain steering control.

Is it possible for ABS to cause the brake pedal to go to the floor?

ABS does not cause the brake pedal to go to the floor on its own. It helps maintain control during hard braking by preventing the wheels from locking up. Other brake system problems usually cause the brake pedal to go to the floor.

How can a malfunctioning ABS sensor affect the brake pedal?

There is a possibility that a malfunctioning ABS sensor can cause a brake pedal problem. The ABS system may forced to activate unnecessarily if an ABS sensor fails. This may affect brake pedal feel. It is not the primary cause of a brake pedal going to the floor, however.

If my brake pedal goes to the floor, what should I do?

For safety reasons, it is crucial to address the issue immediately if the brake pedal goes to the floor. Immediately stop driving the vehicle and take it to a qualified mechanic or repair shop for an inspection and repair. Driving with a brake issue can be extremely dangerous.

Is regular maintenance able to prevent brake pedal issues, including ABS issues?

Brake fluid flushes, brake pad inspections, and proper care of ABS sensors can help prevent brake pedal problems, including ABS problems. Your brake system can operate correctly with routine maintenance.

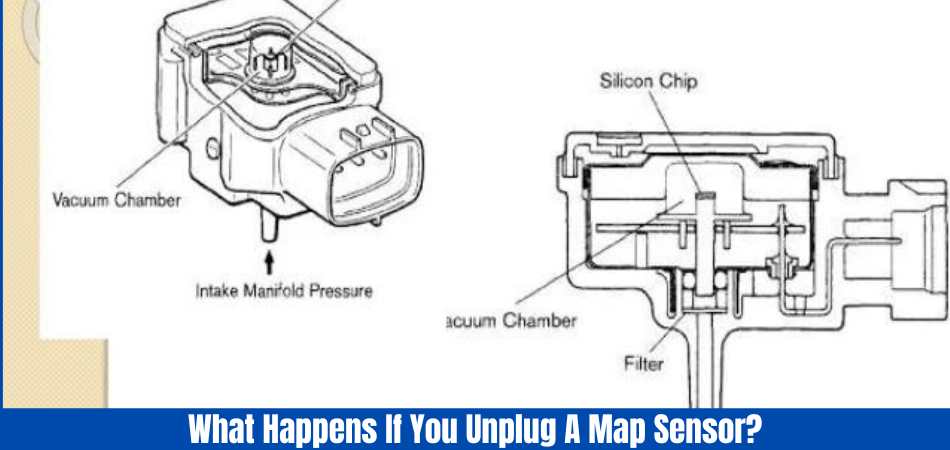

MAP sensors are essential to the electronic control system of fuel-injected engines. By providing information about the pressure inside the intake manifold it aids the ECU in calculating the best air/fuel ratio. Many people, however, are tempted to unplug the MAP sensor due to various reasons. But What Happens If You Unplug A Map Sensor?

Unplugging the sensor is often the answer since it may make the car run smoother. Some cars don’t have a MAP sensor; instead, you’ll find an MAF (Mass Air Flow) sensor. Before unplugging your MAP sensor, you should know what will happen.

So read the article to learn- “What Happens If You Unplug A Map Sensor?”

What Does the MAP Sensor Do?

In fuel-injected engines, the Manifold Absolute Pressure sensor, also known as MAP, plays a crucial role. An ECU receives information about the pressure inside the intake manifold. Based on that data, the ECU calculates the optimal air/fuel ratio for the engine and adjusts fuel delivery accordingly.

MAP sensors work with other engine sensors to provide information about engine load at different RPMs, along with providing information about the pressure in the intake manifold. By adjusting the fuel injection system, the ECU ensures that the engine is running smoothly and efficiently and emitting minimal emissions.

What Happens If You Unplug A MAP Sensor?

There is a tendency for people to confuse the MAP sensor as a non-essential component. So, What Happens If You Unplug A Map Sensor? The system will provide excessive fluid even if it is unnecessary if the MAP sensor is unplugged. The concentration of fluid will change dramatically.

Furthermore, the combusted gas cannot escape and increases internal heat. The results are similar to those of a bad MAP sensor or a failure of the MAP sensor. The story doesn’t end there.

By measuring the manifold pressure, the MAP sensor assists in balancing the air and fuel ratios. What Happens If You Unplug A Map Sensor. If it is disconnected, the ECU will receive inaccurate information about the air-fuel ratio. The fuel will then be converted to lean or rich. As a result, the following issues will arise:

Problem 1: The fuel and air mixture is incorrect

A MAP sensor calculates fuel pressure and allows the engine to serve more fuel if necessary. Unplugged manifold absolute pressure sensors cannot count the pressure or fuel condition.

Furthermore, an incorrect mixture of air and fuel will result in uneven combustion and polluted air.

Problem 2: Mismonitoring of manifold pressure

By reading the manifold pressure, the MAP sensor supplies fuel as needed. The ECU will provide more fuel if the reading goes low. In addition, if the pressure is correct, the ECU will not allow extra fuel to be supplied.

The ECU will not get any or the wrong information if the sensor is not working or unplugged. When this happens, the ECU may supply more oil or stop supplying oil, which can result in severe engine damage or engine failure.

Problem 3: Overdelivery of fuel

The valves may have more carbon deposition as a result of excessive combustion. The engine can lose power and produce less power. The engine can also lose power due to damaged or malfunctioning spark plugs (our pick).

Problem 4: Check the engine light

An unplugged MAP sensor can be annoying and cause the check engine light to illuminate, although this is not a common fact. Even after plugging in the sensor, it may still be on. In that case

- Ensure that the engine is off.

- Make sure the sensor is clean by cleaning it

- Reset the car’s computer system

- Turn the engine on

- Start the engine after a few minutes.

This is a quick way to turn off the light. However, if the problem is not with other sensors, it could be with MAP sensors. To fix it, go to an auto repair shop.

Problem 5: Lack of fuel and clogged fuel filter

Even though the engine gets enough fluid and pressure, it will sound like there isn’t enough oil in the system or reservoir. If that is the case, you can add more oil. Due to faulty combustion, all the consequences will result in dirty oil.

In the end, these conditions will result in a damaged fuel pump and a clogged fuel filter (our recommendation). Having clogged fuel filters and a damaged power pump will result in less power and dirty oil that cannot be used.

Problem 6: Starting Problems

Starting will be difficult if the fuel is lean or rich, as it cannot lubricate properly and inhibits more power production. Oil that is too lean or too rich also performs poorly. This will result in a rough start for the engine.

Problem 7: Poor running of the car

The engine’s performance will be affected by an unplugged MAP sensor. When you unplug the MAP sensor from your vehicle, you will not be able to drive smoothly. A fluid imbalance will occur in the system, resulting in improper lubrication. As a result, the car runs rough.

Problem 8: Poor engine performance

An engine-related mismanagement directly affects the engine. A manifold with incorrect oil and air ratios will not perform well without proper pressure. In addition, dirty oil can clog the pathway.

All these problems prevent the engine from working at its maximum capacity.

Problem 9: Damage to the engine and exhaust system

By removing harmful gases from the engine, the exhaust system aids combustion. Additionally, it improves the performance of the engine. Unplugging the MAP sensor will prevent the exhaust system from removing harmful gases.

Furthermore, the fuel will not be able to eliminate the gases due to the lack of evaporation. Parts can last longer if they are fuelled with fresh fuel. Unplugged MAP sensors result in fuel and combust harmful gases, damaging the engine and exhaust system.

Furthermore, the gas that has been combusted does not go out. Consequently, it damages the entire system by mixing with the oil.

The problems listed above are all linked. The majority of problems will appear if you unplug the MAP sensor.

All of these problems can be resolved by adequately plugging the MAP sensor and replacing it if it isn’t working. Contact an automobile repair expert immediately if you continue to receive incorrect information after replacement.

Why Would a Vehicle Run Better After Unplugging the MAP Sensor?

Unplugging your MAP sensor might improve the performance of your car now that you know what it does. Your car will run poorly or have reduced power and fuel economy if there is a problem with the MAP sensor. Nevertheless, unplugging the sensor can sometimes “reset” the ECU and improve its performance. This may occur for several reasons:

1. Malfunctioning Sensor

When the MAP sensor malfunctions, it can send incorrect signals to the ECU, causing a variety of problems. It is possible to eliminate the incorrect signals by unplugging the sensor, thereby improving the efficiency of the ECU.

2. Sensor calibrated incorrectly

If the MAP sensor is not calibrated correctly, the ECU may inject too much or too little fuel, resulting in poor performance. By unplugging the sensor, the ECU can sometimes re-calibrate the sensor correctly after it has been reset.

3. Dirty or clogged sensor

In the event that the MAP sensor becomes clogged or dirty, it will send incorrect signals to the ECU, which can result in a variety of problems. A clogged or dirty sensor can be compensated for by unplugging the sensor, allowing the ECU to operate more efficiently.

4. Problems with the engine or fuel system

Unplugging the MAP sensor can mask other engine or fuel system issues that cause poor performance. It is essential to address the underlying problem as soon as possible since this is not a permanent fix.

Is it Possible to Drive with the MAP sensor unplugged?

If the MAP sensor is faulty, you can drive with it unplugged, and the car may run better as a result. The problem with that is that it can do more harm than good. With the MAP sensor unplugged, a vehicle will run too lean or too rich, which will cause the combustion area to run much hotter, causing damage to the block, pistons, catalytic converter, etc.

It would be best if you only considered running without the MAP sensor if it is so faulty that you cannot drive without it. If the sensor is unplugged, you can drive the car, but I would advise replacing it as soon as possible.

Why Does the MAP Sensor Fail?

MAP sensors are susceptible to contamination, as are most electric sensors. A map sensor that uses a hose can become clogged or leak, making it impossible to read pressure changes.

Extreme vibrations cause some cases of external damage during driving. Due to the proximity of the engine, electrical connectors can also melt or crack from overheating. It will be necessary to replace the MAP sensor in either of these scenarios.

What are the Symptoms of a Bad Map Sensor?

An engine’s air-fuel ratio will be affected by a faulty MAP sensor. An incorrect ratio will result in the engine’s ignition occurring at the wrong time in its combustion cycle. A prolonged period of severe pre-detonation will damage the internal engine parts (such as pistons, rods, and rod bearings) and eventually cause catastrophic failure. Here are some warning signs to look out for:

1. Poor Fuel Economy.

When the ECM detects low or no vacuum, it assumes the engine is under high load, so it dumps in more fuel and advances spark timing. Detonation may occur as a result of excessive fuel consumption, poor fuel economy, and poor fuel economy.

2. Power deficiency.

If When the ECM detects a high vacuum, it assumes the engine load is low, so it cuts fuel injection and retards spark timing. A decrease in fuel consumption is a good thing on the surface. In contrast, if the engine consumes too little fuel, it may be unable to accelerate and pass.

3. Inspection of emissions failed.

A broken MAP sensor increases harmful emissions because fuel injection does not correspond to engine load. Insufficient fuel may lead to higher nitrogen oxide (NOx) emissions, while excessive fuel causes higher hydrocarbon (HC) and carbon monoxide (CO) emissions.

4. Rough Idle.

An insufficient fuel injection system leads to rough idling and perhaps even random cylinder misfiring.

5. Hard Starting.

Similarly, an excessively rich or lean mixture causes the engine to have difficulty starting. You may have a problem with the MAP sensor if you can only start the engine when your foot is on the accelerator.

6. Stalling or hesitating.

A faulty MAP sensor may cause an ECM to give you a lean mixture when you are starting from a stop or attempting a passing maneuver.

7. Check Engine Light.

MAP sensor diagnostic trouble codes (DTCs) can range from simple circuit, sensor, or correlation faults to range or correlation faults, depending on your vehicle’s age. The ECM may receive false data from a failing MAP sensor, such as low engine vacuum, when the throttle position sensor (TPS) and crankshaft position sensor (CKP) both show idle.

How to Diagnose a Bad MAP Sensor?

The easiest way to confirm a faulty MAP sensor is to plug the car into an OBDII diagnostic machine and check for faults. If the check engine light is illuminated and the MAP sensor is the cause, it will be stored in the car’s fault memory. If there is no stored fault, then diagnosing a faulty MAP sensor is slightly more involved.

Here’s my method of inspecting a faulty MAP sensor:

1. Look for warning signs.

Check engine lights may indicate a faulty MAP sensor. To confirm a defective sensor, plug the car into a code reader. In some cases, there may be more than one similar fault code stored, so you may need to clear the fault codes and see which comes back on.

2. Vacuum hose for MAP sensor should be checked.

Ensure the vacuum hose connected to the MAP sensor is free of cracks, leaks, or damage. A damaged hose can cause a vacuum leak, affecting the MAP sensor’s readings. The car will usually idle rough if the vacuum hose is split.

3. Connect the MAP sensor electrically.

Connect the MAP sensor and make sure there are no damaged pins. Poor connections can cause the MAP sensor to malfunction, causing the check engine light not to illuminate or to flash erratically. Make sure the wires coming from the sensor are not damaged or disconnected.

4. MAP sensor test

The voltage output of the MAP sensor should be tested with a multimeter. Variations in voltage output should be caused by changes in engine load, e.g., revving the engine. When a vacuum is applied to a MAP sensor, you can look for a drop in voltage at specific vacuum pressures using a vacuum gauge and a multimeter.

When your engine is running rough, you can take an educated guess by simply unplugging the MAP sensor if you do not have access to a diagnostic machine. It is possible to assume the MAP sensor is the problem if the car runs smoothly without it plugged in. However, this is not a guarantee.

How To Replace A Faulty MAP Sensor?

Replacement of a failed sensor varies from vehicle to vehicle. You can use these notes below as a reference for the next replacement project, as some basic procedures are nearly identical.

If you lack experience with self-projects, consult and ask a professional about any details to ensure a smooth process.

- MAP sensors should be located on the intake manifold, either near or on top of the throttle body or on the intake manifold itself.

- Sensor screws and nuts should be removed.

- Make sure the electrical connection is disconnected. You should avoid using force to remove the connector, as it may contain a locking tab that must be removed before it can be unlatched.

- Ensure that the vacuum hose is disconnected from the sensor if necessary. Replace the suction pipe with a new one.

- Analyze the differences between the old and new sensors.

- Suction hoses may need to be reconnected if necessary.

- Connect the electrical connection to the sensor again.

- Replace any screws or nuts holding the sensor in place.

- Make sure all connections are stable before proceeding.

Conclusion: What Happens If You Unplug A Map Sensor

Now you might have some idea of What Happens If You Unplug A Map Sensor. It is essential to understand the risks and consequences of unplugging the MAP sensor, even though it might seem like a quick fix for poor performance. A malfunctioning MAP sensor can reduce fuel economy and increase emissions in your car’s engine management system.

In order to ensure your car runs smoothly and efficiently, it’s essential to diagnose and address MAP sensor problems promptly. Knowing how the MAP sensor works and the possible reasons behind poor engine performance can help you make informed decisions about maintaining and repairing your car.

Read more of our articles here.

Read Also: Unplugging your MAP sensor: What you need to know!

FAQs

What Happens If You Unplug A Map Sensor?

It disrupts the communication between a MAP sensor and an ECM when the sensor is unplugged. As a result, the engine’s performance may be affected.

If I unplug the MAP sensor, will the engine still run?

Engines may run in some cases, but they will likely operate in a default or limp mode. As a result, fuel efficiency and performance may be reduced due to pre-programmed settings.

What is the effect of unplugging the MAP sensor on fuel efficiency?

When the MAP sensor fails to provide accurate pressure data, the ECM may have difficulty adjusting the air-fuel mixture. A decrease in fuel efficiency can result from inefficient combustion.

Are there any warning lights on the dashboard if the MAP sensor is unplugged?

Most modern vehicles will display a check engine light (CEL) if the MAP sensor is unplugged. When the MAP sensor does not provide data, the ECM signals a malfunction.

Is it possible to drive temporarily without the MAP sensor plugged in?

Leaving the MAP sensor unplugged for an extended period of time is not recommended. Engines can run, but they may not perform optimally, resulting in reduced performance and increased emissions.

Duralast offers a variety of automotive parts and accessories, including brakes, batteries, and engine parts. The brand is owned by AutoZone, a leading retailer of automotive parts and accessories in the United States. For many makes and models, Duralast products meet or exceed the quality of original equipment manufacturer (OEM) parts. Duralast sells replacement parts and accessories for non-warranty vehicles in the automotive aftermarket. But the question is Is Duralast a Good Brand?

Duralast products are known for their high quality and affordability. There are, however, those who criticize it and those who support it. Duralast products may be reliable to some people, but they may be inferior to others who have had negative experiences with the brand. To provide a balanced view of the pros and cons of using Duralast products, this blog post examines the various factors that may influence Duralast’s reputation as a good brand.

An Overview Of Duralast’s History

AutoZone, a leading retailer of automotive parts and accessories in the United States, founded Duralast. In 1979, AutoZone was founded by J.R. “Pitt” Hyde III in Forrest City, Arkansas. As a single store, the company quickly expanded to multiple locations across the country selling automotive parts and accessories. During the 1990s, AutoZone started selling private-label Duralast products. In addition to meeting or exceeding OEM quality standards, these products were available at a lower price point than many OEM parts.

Duralast has evolved and expanded its product portfolio over time. In addition to brakes, batteries, engine parts, and more, the brand offers a variety of automotive parts and accessories. A popular choice among DIY mechanics and professional technicians alike, the brand focuses on quality and affordability.

The Duralast Gold line of products was launched in 2002, marking an important milestone in the brand’s history. With a limited lifetime warranty, these products are designed to offer the highest level of quality and reliability. Through the Duralast Gold line, the brand established itself as a reliable source of automotive parts and accessories.

In Due to changing consumer preferences and market trends, Duralast has undergone some changes and updates in recent years. A range of products are now available for purchase on the brand’s website and in its retail stores, for example. As well, Duralast has introduced numerous new product lines and categories, including Duralast Elite, which features high-performance parts for racing. While maintaining its focus on quality and affordability, Duralast has evolved and adapted to the changing needs of its customers.

Where Are Duralast Parts Made?

With parts manufactured all over the world, including Mexico, India, and beyond, Duralast offers a wide selection of automotive parts. We have everything you need, whether you’re looking for a reliable replacement part or something to keep your car running smoothly. Their reputation can attributed to the following factors:

- They offer affordable parts that are ideal for budget-conscious consumers.

- The materials they use are of high quality and can withstand wear and tear for a long time.

- It has been operating since the 1920s and is a trusted shop for all types of automotive repairs.

When shopping for new or replacement parts for your vehicle, Duralast is an ideal choice because they offer quality parts at competitive prices. One of the most popular names in automotive repair and maintenance today is because of their wide selection and easy-to-find locations.

With Duralast, consumers can rest assured that they’ll get dependable parts from a reputable source no matter what their budget is. It’s clear why so many people choose Duralast when considering which brand to buy for auto repairs or replacements based on this information.

Is Duralast a brand of Autozone?

AutoZone’s Duralast brand offers reliable parts at affordable prices that meet or exceed OE specifications. Private label parts feature a lifetime warranty and an internal regulator to ensure they work in hot and cold temperatures.

Furthermore, Duralast’s competitive prices allow customers to shop around and find the best deal for their buck on its wide variety of auto parts. A Duralast part manual isn’t always necessary when buying one, but it can provide additional peace of mind as it contains detailed instructions on how to properly install and use it.

Duralast parts have proven to stand the test of time when tested under real-world conditions. A trusted name in automotive retailing, this AutoZone brand consistently delivers quality products from batteries to brakes and alternators. Thus, it is an excellent choice for those seeking quality and durable aftermarket auto parts at great prices.

What are the Products Offered By Duralast?

Duralast offers an extensive selection of automotive parts and accessories, such as brakes, batteries, engine parts, and more. Duralast products offer the following benefits and features:

Quality: Quality products are designed to meet or exceed the quality of OEM parts and are tested to ensure they meet the highest performance and reliability standards.

Affordability: For those looking to save money on automotive repairs and maintenance, Duralast products are often more affordable than OEM parts.

Wide range of products: There is a wide range of Duralast products available for vehicles of all makes and models, including domestic and imported ones.

Limited lifetime warranty: A limited lifetime warranty is included with many Duralast products, offering customers additional peace of mind and protection.

Duralast Gold line: In addition to offering the best quality and reliability, Duralast Gold products also come with a limited lifetime warranty.

Duralast Elite line: In addition to racing brakes and suspension components, Duralast Elite products designed for high-performance applications.

Automotive aftermarket products manufactured by Duralast for vehicles that are no longer covered by a manufacturer’s warranty. Its products are popular with DIY mechanics and professionals alike and are suitable for use in a variety of industries and markets, including automotive repair and maintenance, racing, and performance.

What is the Quality of Duralast parts?

Known for their superior quality and exceptional performance, Duralast parts are tough and reliable. Its quality control protocols, rigorous materials, and industry-leading manufacturers make Duralast a good brand for affordable automotive products that perform as well or better than original equipment.

It has been reported that Duralast products last longer than other brands, rebuild better than expected, and come with a lifetime warranty. Ford parts have been my go-to brand for years without any issues and I’m confident they’re not junk. When combined with AutoZone’s excellent customer service, Duralast offers customers a great value proposition when it comes to automotive repairs.

With our products, customers are assured they are getting top-quality parts that won’t break the bank. Although there are some negative reviews about Duralast out there, overall the consensus is that it is a great option for car owners seeking high-quality parts at a reasonable price.

Is Duralast A Good Brand?

Is Duralast a Good Brand? Duralast is undoubtedly one of the most reliable and reputable brands on the market, making it a good brand. In the continental United States and some international markets, Duralast manufactures and distributes everything from engines to tie-rods.

Both consumers and large professional institutions respect Duralast in the auto parts market. You should definitely consider Duralast if you’re looking for a brand backed by professionals. You can consider them a safe choice for your auto parts needs because of their respectable business practices and fair and equitable warranty agreements.

Is Duralast A Good Brand Cost-Wise?

Duralast is pretty middle of the park in terms of their actual cost breakdown, even though their overview painted them as an optimal choice. Parts provided by them are generally durable and good quality. So cost-wise Is Duralast a Good Brand?

Most people, however, find them too expensive. This is especially true when comparing alternative manufacturers or alternative marketplaces. The quality-to-cost ratio that Duralast uses may only fit a small window of people whose budget matches it.

Many people tend to either choose something cheaper that is somewhat poorer in quality or something a little more expensive that is quite a bit better in quality. Towards the end of the article, we’ll discuss which manufacturers or marketplaces are a little pricey but quite good.

Is Duralast A Good Brand Reliability-Wise?

Whenever you choose Duralast, you can assured that you are getting a part that will stand the test of time if you find that what they have to offer meets your needs. While they offer a decent warranty on some of their parts, they are vastly inferior to other sellers like AutoZone. So Is Duralast A Good Brand Reliability-Wise?

For example, AutoZone (for example) offers a lifetime warranty on axles, which Duralast might give you a multi-year warranty on. What are your thoughts on Duralast parts 10 years from now, even if you felt inclined to believe they were slightly better? Duralast axles that are 10 years old will they still perform as well as a brand new free replacement axle? It might be possible, who knows? Probably not, though.

Is Duralast Ignition Coils a Good Product?

Duralast ignition coils provide reliable, durable performance, allowing you to hit the road with ease and peace of mind. A brand like Duralast offers high-quality auto parts at an affordable price. Their ignition coils guaranteed for a lifetime and meet or exceed OE standards.

Duralast products have received positive reviews from many users, suggesting they’re worth considering for certain vehicles. Some users, however, have reported negative experiences, suggesting OEM parts may be better suited to certain applications.

It depends on the specific product and vehicle application whether Duralast ignition coils work well. Before making a purchase decision, do your research and speak with a professional mechanic to ensure that you’re getting the best possible product.

You should compare both brands before choosing one before choosing one. Napa also offers similar products at competitive prices.

How Good Are Duralast Suspension Parts?

Are you looking for durable suspension parts? Duralast suspension parts are like sturdy anchors, ensuring smooth and comfortable rides for years to come. With heavy-gauge steel and resilient components, they meet or exceed OE performance standards.

Duralast manufactures durable parts with high-quality materials, making them accessible to the market. There are a range of positive and negative reviews for this product, suggesting it may be a better option for certain vehicles than OEM parts or other aftermarket brands like Moog. Purchasing a product, however, requires research.

How Good are Duralast Brake Pads?

The Duralast brake pads are a great choice if you concerned about your safety. There are several options available from the brand, such as Duralast Gold brake pads and standard brake pads. AutoZone offers lifetime warranties on both items. For reliable braking power at an affordable price, our products meet or exceed OE quality, performance, and durability standards.

Besides being compatible with most vehicles, their high-quality products provide excellent stability as well. According to users, Duralast’s brake pads produce less dust and have a five-year lifespan.

Is Duralast a Good Car Battery?

Duralast known for its long-lasting power and reliable performance when it comes to car batteries. AutoZone’s website has an average rating of 4.7 out of 5 stars from customers. Also, Consumer Reports rated the 51R-DLG model as a recommended battery with excellent cold cranking and life ratings. There are several models offered by the company, such as the Gold and Platinum series, which provide optimal performance in all types of vehicles. In addition to offering a lifetime warranty, Duralast also offers a wide range of car battery options. Is Duralast A Good Brand Reliability-Wise?

In light of all these factors, Duralast is clearly a good brand of car batteries. You can replace or exchange your battery if something goes wrong with it, even if you’ve been using it for years. Having an AutoZone nearby can be a great idea in an emergency. With Duralast’s lifetime warranty, even if your battery dies after a while, you’ll protected.

Can Duralast Wheel Bearings be trusted?

You can count on Duralast to provide a reliable wheel bearing at a reasonable price! Wheel bearings offered by AutoZone under the Duralast brand as well as the Duralast Gold brand. Durability and reliability are excellent features of the Gold option for those seeking superior performance.

Besides being factory-sealed and lubricated for life, their products come with lifetime warranties. Wheel bearings from Duralast tend to receive positive reviews from users. While some have found them to be an affordable alternative to more expensive OEM parts, others have experienced excellent quality and performance. Nevertheless, some say Timken may be a better choice for certain vehicles than other brands.

Take all of this information into consideration when deciding whether Duralast is the right brand for you. You can get the most bang for your buck without compromising safety or quality by researching FAQs and similar posts from other consumers before making a decision.

What is the lifespan of Duralast rotors?

Rotor life expectancy for Duralast rotors will range from 25,000 to 85,000 miles. A number of factors can affect the lifespan of automotive parts. Rotor longevity can affected by your driving habits, your vehicle’s condition, and how well you maintain it.

In general, rotors designed to last a long time, but eventually, they will wear down and need replacing. As a result of their quality and their usage, rotors can wear down at different rates. A well-maintained and high-quality rotor may last longer than a poorly maintained or lower-quality rotor.

Rotors should maintained according to the manufacturer’s recommendations and replaced when worn. It is important to check the condition of your rotors on a regular basis and to replace them when necessary to ensure the safety and performance of your vehicle.

What is Duralast’s warranty period?

Specific Duralast warranty terms will vary based on the product that you have purchased. To find out more about the warranty for a specific Duralast product, you can refer to the product documentation or contact AutoZone directly. Most Duralast products covered by a limited lifetime warranty at AutoZone, which means that they are covered for as long as you own them. Please read the warranty carefully and understand its terms and conditions, as some exclusions and limitations may apply.

Is Duralast a good brand compared to Autopartswarehouse and Autozone?

As these three marketplaces are highly comparable, they tend to appear in the same conversations. It should noted that each of them offers different benefits and is quite different from the others. As an example, Duralast built to last, whereas Autozone built to be decent, but also reasonably inexpensive to replace. Is Duralast A Good Brand?

In comparison to Duralast, Auto Parts Warehouse offers a nice blend between the two, though they don’t always have as many items in stock. It likely depends on what part you are looking to replace and what offers the three brands have if you are in a competition between them.

Unless it is a super niche part that they don’t carry or manufacture, it is always a good idea to browse all three of them. Here is what you should probably consider as your best option in the next section. It’s even better than Duralast.

How Do Duralast Parts Compare To OEM Parts?

No, not really. Duralast is not a bad brand by any means. Duralast’s problem is that their prices are so close to OEM parts that you might as well go with OEM parts since they’re more likely to be better and you already KNOW they’re compatible.

As your mechanic already knows the parts they are working with quite well, they can sometimes fix or replace parts more easily and solve problems more quickly. It’s true that Duralast offers a few % off of the price, but for the sake of (usually) a few bucks, you may as well go with the original manufacturer’s parts.

If you want to purchase parts, a good flowchart would be to buy from OEM unless they don’t carry the part you want for some reason or Duralast is more than 10% cheaper.

Duralast Vs Carquest

Both Duralast and Carquest have their advantages and disadvantages – so which is best for you? With over 60 years of experience in the industry, Duralast is a great choice for affordability and reliability.

When comparing the two, keep these points in mind:

- There are two types of brake pads offered by Duralast: Gold and standard. Both options praised for being stable when braking, producing less dust, and having a long service life.

- The alternators from both brands have received mixed reviews, with no clear winner.

- The quality of a product may vary depending on the type of vehicle and its application. It is important to research thoroughly before making a decision.

After considering all the factors, you should choose an auto part that meets your specific needs as well as your budget. Before investing in either Duralast or Carquest, make sure you read reviews and compare products carefully.

The next step is to compare Duralast Gold with standard Duralast products.

Duralast Vs Duralast Gold

Selecting automotive parts requires considering the differences between Duralast and Duralast Gold – they offer different levels of quality and performance.

Compared to standard Duralast parts, Duralast Gold components engineered to meet or exceed OE quality, ensuring better performance and durability.

Standard Duralast brake pads provide similar performance in normal driving conditions, but Duralast Gold brake pads provide higher quality control and a refined production process. As a result, Duralast Gold batteries offer greater vibration resistance and power, making them ideal for heavy vehicles with high demands, such as those with heated seats or infotainment systems.

In order to ensure you get the best quality and performance for your specific vehicle needs, you should research and compare products from both lines. All of these factors will help you make an informed buying decision that meets your needs.

Duralast Vs Diehard

As both Diehard and Duralast automotive batteries come with their own advantages and disadvantages, comparing them can be tricky. It well known that Duralast batteries are affordable, made with high-quality materials, and have reliable performance. Conversely, Diehard batteries’ cold-cranking amps (CCA) range from 550A to 900A, making them renowned for their exceptional longevity.

There are similar reserve capacity ratings between both brands, but Diehard provides a longer warranty of three years compared to Duralast’s two years. In the end, the right choice depends on your specific needs and what kind of vehicle you are looking for.

To ensure you get the best quality and performance for your car or truck, it is imperative to research and compare both brands’ products before making a purchase decision It is also important to consider factors such as cost, CCA ratings, reserve capacity ratings, and warranties offered by each brand when choosing between Duralast and ACDelco batteries.

Learn more at here.

Duralast Vs Acdelco

Both Duralast and ACDelco automotive parts offer unique benefits and drawbacks, making it tricky to choose between them. Duralast offers great options with its Gold and Platinum battery lines, which highly regarded. Known for their affordability and reliability, they provide reliable performance.

As well as having a good reputation, ACDelco batteries offer a variety of CCA ratings. The Duralast models have reported to last longer by some users. There are viable options for both brands when it comes to brake pads. There limited information available about ACDelco’s offerings in comparison to Duralast’s, but Duralast’s Gold and standard brakes offer solid performance.

Overall, you should research both brands’ specifications and how they fit your vehicle needs before choosing between them. To ensure your car or truck has the best quality and performance, you should consider all aspects before buying. It’s important to compare before making a decision – what works best depends on individual requirements.

Duralast Vs Valucraft

There are two brands that offer different levels of quality and performance when it comes to automotive parts: Duralast and Valucraft. Because Duralast parts made of high-quality materials, they provide reliable performance while remaining affordable.

In contrast, Valucraft parts are cheaper, but they may not perform as well. Valucraft brake pads and rotors may not perform as well or last as long as Duralast brake pads and rotors. A Duralast part also comes with a longer warranty than a Valucraft part.

Duralast Vs Wagner Brake Pads

Choose between Duralast and Wagner brake pads, two brands with different levels of performance and quality. Duralast’s reliability and affordability make it a popular product. Duralast Gold and Standard brake pads are affordable options that made with high-quality materials and known for their reliable performance.

Conversely, Wagner offers ThermoQuiet brake pads, known for their excellent stopping power and quiet operation. It has reported that they provide better wear and service life than other brands. Prior to making a purchase decision, you should research the best option for your vehicle’s needs, as both Duralast and Wagner brake pads offer good quality and performance. There are a number of benefits to each option, so you can find the one that suits your needs best.

Duralast Vs Everstart

A comparison of Duralast and uralast and Everstart automotive batteries? Considering the pros and cons of each will help you decide which is best for you. In addition to its affordability and quality materials, Duralast known for its reliable performance. Performance and reliability are highly regarded when it comes to their gold and platinum options.

Conversely, Everstart batteries also considered durable and reliable, with a lifespan of 2- 5 years. They’re sold at Walmart made by a company that produces some of the more premium brands too, offering up to 800 CCA ratings for better cold-cranking performance in some cases.

Despite the fact that both brands offer good quality, you should research each product carefully to ensure that it meets your specific vehicle needs. Depending on your situation, either could be the right choice. Therefore, weigh both equally before choosing which is best for you. Be sure to keep these considerations in mind as you research Duralast vs. OEM.

Do Duralast products have any common issues or complaints?

Customers have reported a range of problems with Duralast products. There are serious quality concerns for some drivers, from wiper blade fitment issues to defective parts such as radiators and battery chargers within a short time period of use.

A remanufactured part, such as an alternator, may not meet the same standards as a new one due to the rebuilding process. Wheel bearings and suspension parts can differ in terms of performance between different vehicles, causing some users to choose other brands such as Moog or Timken.

It is important to do your research and compare products before making a purchase in order to get the best value for your vehicle needs, even if these complaints don’t reflect the brand’s overall quality. If Duralast is right for you, you can make an informed decision. In the coming weeks, we’ll examine Duralast’s quality and reliability in comparison with other automotive brands.

Conclusion: Is Duralast A Good Brand?

Now that you know more about Duralast, you should have a better idea of whether the company is right for you. The brand provides high-quality products that built to last and are certainly reputable. It is clear that Duralast is on par with its closest competitors Autozone and Auto Parts Warehouse. However, Duralast isn’t competitive with most OEM options. You might as well invest a little more in OEM parts.

Read more of our articles here.

FAQs

Is Duralast a reputable brand?

Automotive professionals generally consider Duralast to be a reputable brand. Several auto parts stores and retailers carry their products, and they have been in business for many years.

What is the reliability of Duralast products?

The Duralast brand is known for its reliability. Batteries and brake parts are essential auto parts that many consumers trust for their durability and performance.

What kind of warranty does Duralast offer?

Warranty coverage varies from product to product with Duralast products. If you purchase an item, you should read the warranty details to understand how it is covered.

Compared to other automotive brands, how does Duralast fare?

A number of well-known automotive brands compete with Duralast. Individual preferences and product categories may influence the comparison. Make an informed decision by researching and reading reviews.

Can you tell me where I can buy Duralast products?

Duralast products are available at auto parts stores, online retailers, and even some large general merchandise stores. To find the closest location, check the Duralast website or contact a local retailer.

Have you been having problems with the blower motor on your car? You may need to bypass the blower motor resistor if this is the case. Our goal in this article is to provide step-by-step instructions on how to bypass blower motor resistor in order to get it working again.

The wiring harness needs to be unplugged from the blower motor resistor in order to bypass a blower motor resistor. In this way, the fan motor will be able to run at full power without being constrained by the resistor. You can learn more about the process on how to bypass blower motor resistor and what you need to do to ensure a successful bypass by reading on.

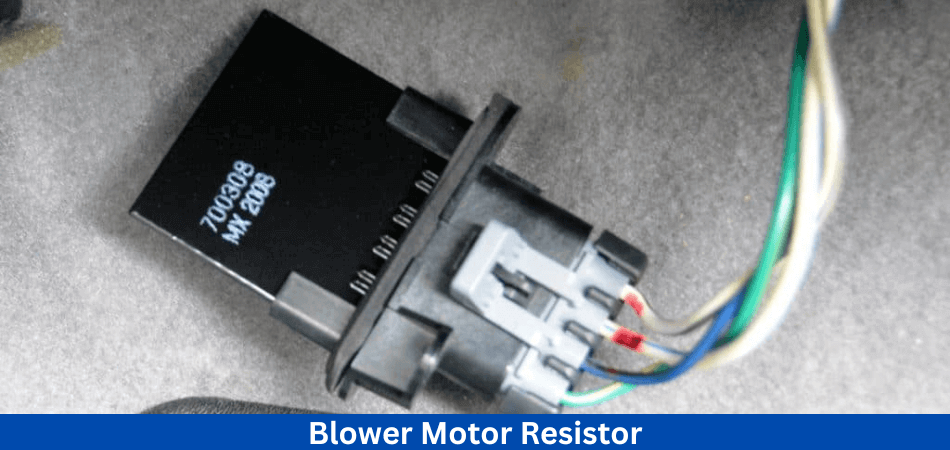

What Is a Blower Motor Resistor?

An actual blower motor switch is the switch or button on the dash that you use to boost or decrease the blower motor’s speed. A fan is the only one that powers the blower motor. Rather than simply stopping and restarting, the blower motor can operate at a variety of speeds thanks to the resistor. The blower motor cannot regulate the fan speed when a resistor fails in the blower motor. In this case, the fan will only operate at its maximum speed, and it will not allow the air to escape.

Blower motor problems can indicated by fluctuating fan speed or running out blower motor resistors. An HVAC system uses a blower motor resistor to control the speed of the blower motor and prevent overheating. Replacing the resistor is not necessary if you know the problem is not due to the resistor. It is best to replace the resistor if you notice any of the above symptoms.

What Does The Blower Motor Resistor Connect To?

It is traditional to ground and wire the resistor in series with the blower motor assembly when using blower motors. Controlled by a resistor that differs in resistance from blower motor to blower motor. This controls the current flowing through the blower motor.

Resistors located close to the air cabin filter are easy to replace because they are simple to replace. If the resistor is faulty, the blower will only run at one speed with the HVAC controls and not at any other speed. There is a blower motor resistor behind the glove compartment or at the bottom of the HVAC housing. It may be necessary to use tools to remove the glove box on some vehicles, but it may not be necessary in others.

To remove the resistor, the wiring harness must disconnected and the screws removed. The garage is a good place to store your blower motor if it is not functioning in the middle of summer. If you don’t want to invest in new equipment, here are some easy steps to replace a blower motor. By using the FIXD Sensor and app, you can monitor the health of your car at all times.

It may caused by corrosion or overheating when your blower motor resistor fails. Motor current controlled by the resistor, which is a mechanical device. Overheating and failure of the resistor may result if the resistor is overrun. During certain conditions, the fuse on the resistor board may blow, resulting in a reduction in blower speed. In the event that the resistor fuse blows, your car will continue to run at high speeds, but it will need to replaced.

Where Is The Resistor Located In Blower Motor?

Usually, the heater blower motor resistor located underneath the dashboard. Within the compartments of the heater and air conditioner, it can found. An air conditioning system device controls the blower motor fan.

An electrical component resistor (also called a blower motor resistor) can prevent current flow into the blower fan. Fans can sped up or slowed down using this feature. Slower rotation of the fan causes less air to circulate throughout the cabin, which reduces resistance. A faulty blower motor resistor will result in heat loss and air loss in your automotive HVAC system. To replace a good one, here are some suggestions.

In the open circuit, the Ohmmeter registers infinity, which indicates the blower resistor needs to be replaced. In this way, the system will remain more uniform, and a cause may even be discovered.

Can You Bypass A Blower Motor Resistor?

An electronic blower motor resistor regulates the motor’s speed through an electronic control system. As well as the blower motor and the control switch, the resistor connected in series with them. Control switches control the voltage applied to blower motors. By changing the resistance in the circuit, the blower motor resistor controls the speed of the blower motor. In most cases, the resistor locates near the blower motor in the air duct.

So how to bypass blower motor resistor? Actually it won’t be difficult to bypass the blower motor resistor. There are a few steps involved in replacing the resistor, in addition to finding and disconnecting it. It is important to have a resistor in the cooling system. The amount of current flowing through the motor can control its speed. An automobile’s climate control system includes a blower motor resistor. A blower motor’s speed is controlled by this device by controlling the flow of current through it. Additionally to regulating the air temperature in the vehicle, it determines the speed at which it circulates.

What are the Signs of a Bad Blower Motor Resistor?

Although they are pretty darn reliable, blower motor resistors can go bad without much warning. The good news is that a blower motor resistor can diagnosed fairly easily.

A bad blower motor resistor can identified by some of the following signs:

- Inability to control HVAC fans (all or certain speeds)

- Only the highest speed setting works on the fan

- There is no air coming from the vents

- A fan that runs intermittently or inconsistently

According to our story above, you’ll likely first notice the problem when the passenger cabin in your vehicle doesn’t cool down or heat up as it normally would-which brings us to an important point. In addition to affecting your HVAC system’s ability to heat up and cool down, a bad blower motor resistor directly affects airflow.

How to Bypass Blower Motor Resistor?

Resistors on blower motors can fail and need to replaced in some cases. The blower motor can become noisy and cause reduced air flow. It is necessary to bypass the blower motor resistor in order to solve this problem. So how to bypass blower motor resistor?

Finding the blower motor resistor is the first step in bypassing it. The rectangular shape of this component can identified on the firewall of a vehicle. The rectangular shape of this component can identified on the firewall of a vehicle.

After installing the bypass wire, the next step is to connect it to the power supply. The positive terminal of this wire should be connected to the positive terminal of the blower motor, and the negative terminal should connected to the negative terminal. When this done, the blower motor will be able to operate at its full speed since the resistor will bypassed. Lets learn all the method on how to bypass blower motor resistor.

Method 1: Direct Wiring

Bypassing the blower motor resistor, direct wiring connects the blower motor directly to the power source. Manually adjusting the power supply to the motor allows you to control the fan speed.

Step-by-step guide

Follow these steps to bypass the blower motor resistor using direct wiring:

- Remove the wiring harness: Carefully remove what found near the blower motor itself or in the HVAC system’s ductwork.

- Disconnect the wiring harness: Disconnect the wires connecting the blower motor to the resistor.

- Power and ground wires: Locate the power and ground wires connected to the blower motor. If necessary, refer to the wiring diagram for your vehicle.

- Cutting and stripping the wires: Use wire cutters/strippers to cut the wires leading to the blower motor resistor. To expose the wire conductors, remove a small portion of insulation from the cut ends.

- Connect the power and ground wires: Connect a 12V power source directly to the blower motor’s power wire, such as the battery’s positive terminal. A suitable ground point, such as the vehicle chassis, should connected to the ground wire.

- Insulate the connections: Cover each wire connection with electrical tape as a short-circuit protection measure.

Pros and cons of the direct wiring method

The advantages and limitations of direct wiring are as follows:

Pros:

- Bypass method that is simple

- Directly controls the speed of the blower motor

- Resistor replacement is a cost-effective alternative

Cons:

- For desired fan speed, the power supply may need to be manually adjusted

- If operated at high speeds for extended periods, it can strain the blower motor

- It does not provide the original functionality of the blower motor resistor, such as automatic speed adjustment based on temperature

Method 2: Using a Bypass Harness

Using a bypass harness, the blower motor is directly connected to the power source, bypassing the blower motor resistor. As a result, the bypass process has simplified, and the connection has been made more organized and secure.

Installation process

You can bypass the blower motor resistor by installing a bypass harness as follows:

- Make sure you purchase a bypass harness that is compatible with the make and model of your vehicle.

- To prevent any electrical mishaps during installation, disconnect the vehicle’s battery.

- Identify the blower motor resistor. The blower motor resistor is usually located near the blower motor or inside the ductwork of the HVAC system.

- Carefully disconnect the wiring harness that connects the blower motor resistor to the vehicle’s electrical system.

- Through the wiring harness previously attached to the resistor, connect the bypass harness to the blower motor.

- Make sure all connections are secure and properly seated. Any additional steps or recommendations should followed according to the manufacturer’s instructions.

- To restore power to the vehicle’s electrical system, reconnect the vehicle’s battery once the bypass harness has installed.

Pros and cons of using a bypass harness

There are several benefits and considerations to using a bypass harness:

Pros:

- Provides a plug-and-play bypass solution that simplifies the bypass process

- Minimizes the risk of electrical problems by ensuring secure and reliable connections

- Makes it easier to remove and reinstall if necessary

- Ensures that the electrical system of the vehicle maintains its original integrity

Cons:

- For your specific vehicle, you will need to purchase a compatible bypass harness

- Compared to other bypass methods, this may be a more expensive solution

- Specific vehicle models may not have harnesses readily available

Method 3: Installing a Resistor Pack

You can also bypass the blower motor resistor by installing a resistor pack. A new group of resistors substituted for the faulty one, providing a fixed resistance value. By using the resistor pack, the speed of the blower motor can be properly regulated.

Locate the resistor in the blower motor of the HVAC system to begin. Identify the faulty resistor and disconnect the wiring harness. Removing the resistor from its mounting location and noting its original location is the first step.

The new resistor pack should now aligned correctly in the mounting location. Make sure the connections on the pack match those on the wiring harness. Be careful not to damage any surrounding components when installing the resistor pack.

Connect the wiring harness to the resistor pack once the resistor pack has been securely installed. Make sure the blower motor is working as it should. With the new resistor pack installed, the blower motor speed should be effectively controlled.

There are pros and cons to using a Resistor Pack to bypass a faulty blower motor resistor. Let’s examine them in more detail:

Pros and Cons of Installing a Resistor Pack

Pros:

- The resistor pack ensures adequate regulation of the blower motor speed by providing a fixed resistance value. In this way, the cabin airflow can maintained.

- Specific vehicle models are compatible with resistor packs, which ensure a seamless fit and electrical compatibility. As a result, compatibility issues during installation reduced.

- Compared to more complex methods such as modifying the wiring harness, installing a resistor pack is relatively straightforward. Many vehicle owners can do this project themselves with basic automotive knowledge and the right instructions.

- By removing the resistor pack and reinstalling the original resistor, you can return to the original blower motor resistor configuration. By doing this, flexibility provided as well as the ability to switch back if necessary.

Cons:

- Specific vehicle models may require different resistor packs, so they may not be universally applicable. To avoid compatibility issues, make sure the resistor packs you purchase are compatible with your vehicle’s make and model.

- In spite of the fact that a resistor pack regulates blower motor speed, it does not entirely bypass the resistor. There is still some resistance in the circuit due to the pack acting as a resistor. It may affect the blower motor’s overall functionality in some cases.

- A resistor pack costs more than a jumper wire, which is a more straightforward method. There can be a wide range of prices for resistor packs based on their brand and quality, as they are typically aftermarket components.

- If a resistor pack installed on the vehicle, the warranty provided by the manufacturer may voided. Check the warranty terms and conditions before proceeding with this method to avoid potential problems.

Method 4: Installing a Variable Speed Controller

A Variable speed controllers allow you to adjust and control the speed of the blower motor. The fan speed can be precisely controlled by installing a variable speed controller instead of bypassing the blower motor resistor.

Step-by-step instructions

Here are the steps to bypass the blower motor resistor with a variable speed controller:

- Your vehicle’s blower motor and electrical system should fitted with the appropriate variable speed controller. Take into account factors like compatibility, installation ease, and features available.

- Before installing the battery, disconnect it as a precautionary measure to avoid electrical accidents.

- You can find the blower motor resistor inside the HVAC system’s ductwork or near the motor.

- Carefully disconnect the wiring harness that connects the blower motor resistor to the vehicle’s electrical system.

- The variable speed controller must connected according to the manufacturer’s instructions. In most cases, the controller connected to the blower motor via the wiring harness that was previously attached to the resistor.

- Make sure all connections are properly seated and secured. Make sure to check the manufacturer’s instructions for any additional steps or recommendations.

- Connect the vehicle’s battery after installing the variable speed controller to restore power to the electrical system.

Pros and Cons

There are several benefits and considerations to using a variable speed controller:

Pros:

- It allows you to adjust the fan speed precisely according to your comfort needs

- Maintains the original wiring integrity of the vehicle’s electrical system

- Reduces blower motor strain by allowing gradual speed adjustments

- Provides automatic fan speed adjustment based on temperature settings, if supported by the controller

Cons:

- This requires the purchase of a variable speed controller compatible with the blower motor on your vehicle

- A controller’s features and specifications may require additional wiring and adjustments during installation

- Variable speed control adds functionality to this bypass method, making it more expensive than other bypass methods

When you understand the precautions, methods, and considerations involved with bypassing the blower motor resistor, you will be confident in using these techniques to regain control over your vehicle’s HVAC system. Always prioritize safety, follow the manufacturer’s instructions, and seek professional assistance if you have any questions. Bypassing the blower motor resistor will provide you with a comfortable and efficient ventilation experience.

How to Troubleshoot a Blower Motor Resistor Bypass?

Several steps can be taken in order to troubleshoot the bypass if it does not seem to work correctly. Check the connections to make sure they are all properly connected. As soon as the connections made, the fuse should checked. For the blower motor to work again, the fuse must replaced if it has blown.

What are the Benefits of Bypassing the Blower Motor Resistor?

- There are several advantages to bypassing the blower motor resistor. It allows you to regain control over the fan speed, ensuring optimal comfort inside your vehicle.

- In addition, it eliminates the need for a potentially expensive resistor replacement.

- Furthermore, bypassing the resistor can provide a temporary fix if a replacement part is unavailable.

Replacing the Blower Motor Resistor

In the event that the bypass is not successful, the blower motor resistor may need to replaced. A new resistor can installed in place of the old one after the old one has removed. Ensure that the new resistor is the same type and size as the old one so that it will fit correctly.

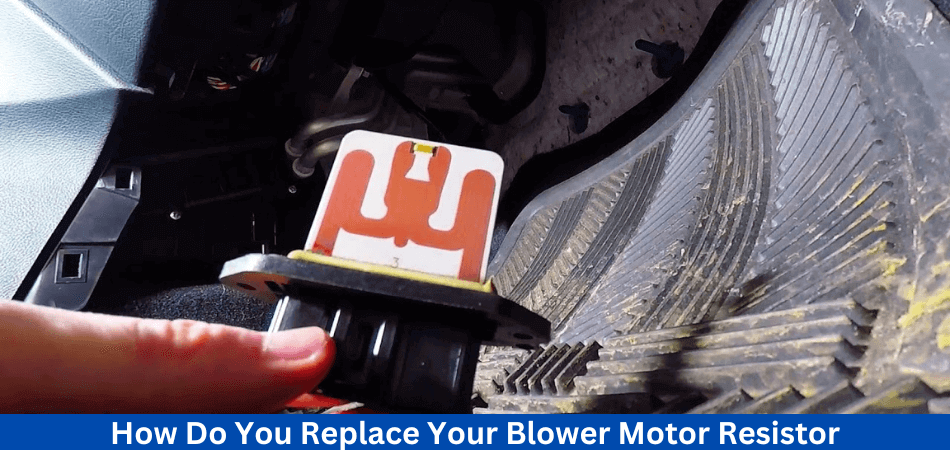

How Do You Replace Your Blower Motor Resistor?

This guide outlines how to replace a faulty blower motor resistor.

- Identify the blower motor resistor

Find out where the resistor for the blower motor is located. The battery is usually found beneath the dash or in the engine compartment on the passenger side. The blower motor is close to it.

- Remove the motor resistor from the blower

Make sure the AC pigtail and cooling duct are disconnected from the components surrounding the blower motor resistor. The blower motor resistor can removed by ratcheting loose the bolts holding it in place. Removing the blower motor resistor is as easy as removing the bolts.

- Remove all wires from the device

The wires attached to the blower motor resistor should cut once the resistor has been removed. Wire strippers or scissors can used to cut the wires.

- Remove the old blower motor resistor and install the new one

Before continuing installation, apply dielectric grease to the housing of the blower motor resistor. By doing this, you will keep water out, a problem that is common when driving off-road. To protect the component, apply a coating to the plastic.

Put the blower motor resistor back where it belongs. Finish the job by tightening the screws and connecting the pigtail.

A pigtail may also worn out if it has already used for some time. If this is the case, proceed to the next step.

- Attach the pigtail to the wire

Reconnect the new wires after disconnecting the worn-out ones. This should be relatively straightforward since most cables are color-coded. The new wires should connected to the connections. You have completed the task by returning the pigtail to its original position.

Preventing Further Damage

Following the replacement or bypass of the blower motor resistor, steps must taken to prevent further damage. It is possible to do this by checking the air filter and replacing it if necessary. Moreover, the wiring may need to checked for damage or corrosion and repaired or replaced if necessary.

Conclusion: How to bypass blower motor resistor?