If your actuator clicking when car is off, it can be a bit disturbing. Most seasoned drivers and mechanics will tell you that actuators make such clicking sounds. If you hear a clicking sound, you should be concerned and work to resolve the issue as soon as possible. Although some actuator-clicking sounds can be alarming, most problems can resolved.

In this article, we explore actuators in more detail. In particular, we investigate why actuator clicking when car is off. We will examine how actuators work in order to better understand the problem. In addition, we will investigate possible ways to fix actuator clicking.

What is an Actuator?

Electrical signals are converted into mechanical motion by actuators. They control various car systems, including power door locks, power windows, and power seats. These components are essential to the proper functioning of these systems and can significantly enhance the comfort and convenience of passengers.

Actuators in cars come in different types. The solenoid actuator is commonly used in power door locks and starter motors, for example. In contrast, linear actuators used in power seats and windows. Your car’s actuators are all crucial to its operation, regardless of their type. Learn more about it here.

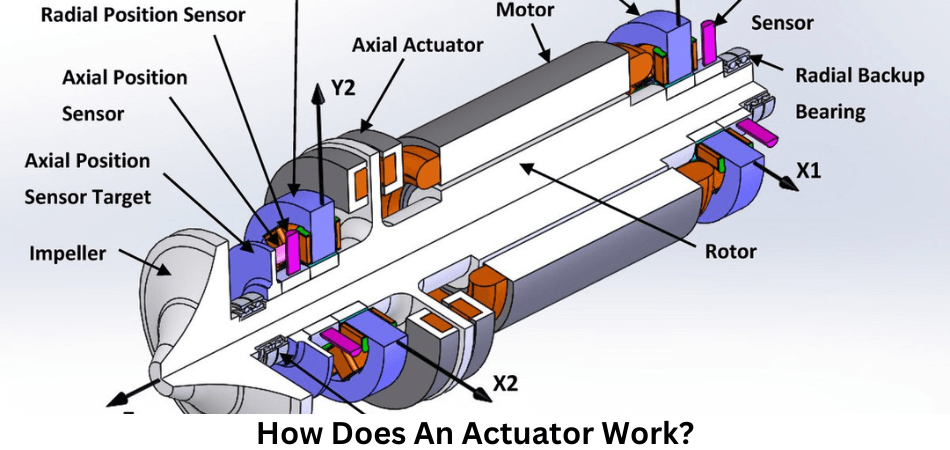

How Does An Actuator Work?

In cars, actuators are devices that convert electrical, hydraulic, or pneumatic signals into mechanical motion or force to control various functions and systems. The following systems can included in these systems:

HVAC (Heating, Ventilation, and Air Conditioning):

In As part of the HVAC system, actuators control the blend doors and mode doors, which regulate the cabin’s temperature and airflow. The car’s vents can opened or closed, the temperature can adjusted, and air can directed to different parts of the vehicle.

Power Locks:

The door locks of a vehicle can be remotely locked and unlocked using actuators. The actuator engages or disengages the locking mechanism when you press the lock or unlock button on your key fob or inside the car.

Power Windows:

The power window actuators raise and lower the windows based on your commands. Window actuators move the window up and down when you press the switch.

Variable Valve Timing (VVT):

VVT (variable valve timing adjust the timing of the engine’s valves, which can optimize performance and fuel efficiency by altering when the valves open and close.

Power Seats:

Actuators control some power seat adjustments, such as moving the seat forward or backward, raising or lowering it, and adjusting the seatback angle.

Throttle Control:

ETC (electronic throttle control) systems are often used in modern cars, where an actuator adjusts the throttle plate’s position in response to accelerator pedal input. As a result, engine power can regulated.

The following is a simplified explanation of how actuators work:

- Input Signal: The actuator operated by an input signal from a control module, such as a button press or a sensor reading.

- Mechanical Action: By converting the input signal into mechanical action, the actuator responds to the input signal. The specific action it controls can involve opening or closing a valve, moving a rod, or rotating a gear.

- Control and Feedback: In many actuators, there are sensors or feedback mechanisms that enable them to watch their position and provide feedback to the control system. When we receive feedback, we are able to ensure that our actions or positions are as we would like them to be.

- Power Source: There are several types of actuators, including electric, hydraulic, pneumatic, and combinations of these. Electric actuators, for instance, generate motion with an electric motor.

In modern vehicles, actuators allow precise control of various systems, enhancing comfort, safety, and efficiency. Onboard computer systems control them to provide a seamless driving experience and are an integral part of the car’s overall functionality.

How Do You Know If Your Actuator Has Problems?

It is possible for your actuator to be defective or malfunctioning if you notice any of these signs. These are some of the most common symptoms to watch out for:

Slow or unresponsive system

The actuator could fail if the system controlled by it (such as power door locks or power windows) is unresponsive or slow to respond.

Clicking sounds

Even if your car is not running, you might hear clicking sounds coming from the actuator if the ignition is off.

Operational inconsistency

Inconsistent operation, such as partial opening and closing of the power windows or stopping mid-operation, might indicate a problem with the actuator.

The system stops working altogether

If the actuator controls a system that stops working completely, it could be a sign that the actuator has completely failed.

And if you notice any of these symptoms, you should address the problem as soon as possible. Furthermore, if the actuator malfunctions, it can cause damage to the car’s electrical system and lead to further problems.

What Causes Actuator Clicking When Car is Off?

A clicking sound may heard on the dashboard after you turn off the engine. Even though this might not seem alarming, it is something to concerned about. In most cases, it has proven to be tricky and engaging, which is why you need a professional to help you find the reason behind the clicking sound. So let’s find out why actuator clicking when car is off.

1) Faulty blend door actuator

The blend door actuator is the leading cause of the clicking noise in the dashboard when the car is off. To regulate the climate control system in the car, the blend door actuator works in conjunction with the temperature sensors. The blend door actuator actually communicates with you when you want cool or warm air in the car. Depending on the actuator, the air will come from different vents in the car. Newer cars with climate controls for the front and back have two actuators for the blend doors.

When the car is off, a clicking noise is most likely to indicate a faulty blend door actuator. It originates from below the dashboard and is incessant. There may also be times when you hear a knock on the door. When you start the engine, you hear this noise, but it’s less common than the clicking noise.

Solution

A professional can help you solve this problem with your car. If you know a little about car mechanics and have a calibrator on hand, follow these steps. Prior to starting, you will also need a blend door actuator.

- Your battery’s negative terminal should disconnected.

- Pull off the retaining knobs on the glove box to remove it.

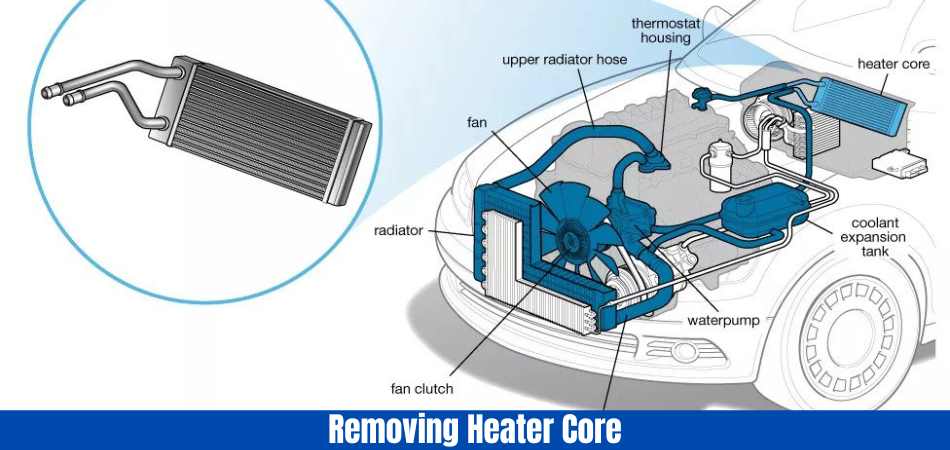

- Remove the wiring harness and locate the heater core, which is normally located behind the glove box.

- In order to remove the actuator for the door, you will need to remove the filter assembly first.

- Rotate the blend door in both directions to test whether it is working properly. As a result, the door will be operating correctly and the new actuator won’t damaged.

- Replace the actuator with the new one.

2) Faulty relay

The majority of your car’s relays located under the hood. In addition to the glove box, you may find relays inside the cabin. It is likely that you will hear clicking sounds even when the car turned off when a relay goes bad. The relay makes the noise when it engages and disengages. It may be necessary to use an OBD-II scanner to determine which relay is faulty or listen carefully to your car to recognize the source of the clicking sound.

Solution

It is relatively easy and inexpensive to fix a relay problem. You will need to purchase and install a replacement. It is important, however, to read the relay and fuse map on the cover to ensure you purchase the correct replacement. It is actually possible to replace a relay by yourself.

3) The HVAC system is uncalibrated

It is the HVAC module that is responsible for controlling the HVAC system’s sensors, motors, and actuators. When the HVAC system is not calibrated, the sensors pick up the wrong figures, causing the module to miscalculate the motor position. With the wrong readings, the motor and actuator will make a clicking sound.

Solution

It is necessary to calibrate the HVAC system again in order to solve this problem. To resolve this issue, follow these steps;

- Start the engine by turning the ignition on.

- For climate control, press the ‘auto’ button.

- Make sure the ignition turned off.

- Switch on the engine after disconnecting the HVAC fuse for one minute. Turn the ignition on and leave it on for two minutes. By doing this, the HVAC system is reset. In order to resolve the issue effectively, you must act quickly.

- For the relearn mode to activated, let the HVAC system run for about 15 seconds.

- Let’s get started.

- On GM cars, this process is used. Using the process illustrated, other cars will calibrate their HVAC systems in a similar way.

4) Faulty stepper motor

The stepper motor is a small component located inside the dashboard. An electromagnetic actuator is a stepper motor. In your car, you’ll find a number of them. Their main function is to control the idle speed of the engine by measuring RPMs per hour. In modern cars, stepper motors are very common. Failure of a stepper motor means a step or a process has been bypassed, and the motor is making noise as a result.

Solution

An expert mechanic can diagnose stepper motor faults correctly by identifying the faulty part. The extent of damage will determine whether a stepper motor can be repaired or replaced.

In order to fix this problem, you need to disconnect the connector on the pigtail. As soon as the stepper motor has been replaced or repaired, you should calibrate the system since the control module has been scrambled and needs to be retrained.

Can Actuator Clicking Be Dangerous?

In general, actuator clicking when car is off is not dangerous. Many different parts of a car use actuators, including the HVAC (Heating, Ventilation, and Air Conditioning) system, power locks, or even the engine’s variable valve timing system. Specific functions performed by these actuators by moving certain components.

An actuator that generates a clicking sound is usually working as intended and engaging or disengaging to control a specific function. There is nothing unusual about this. It is a normal part of the operation of a car. Nevertheless, if the clicking sound is excessively loud, constant, or accompanied by other symptoms, such as a malfunction in the associated system (e.g., a door that does not lock or unlock properly), it may indicate a problem with the actuator.

If If you suspect an issue with an actuator or any other component in your car, you should have it inspected and repaired by a qualified mechanic. When you ignore potential problems with your vehicle’s systems, you may face safety risks or more significant and expensive repairs in the future. In order to ensure the safe and reliable operation of your vehicle, it is critical to resolve any underlying issues promptly.

Can I Still Drive My Car With Actuator Clicking When Car is Off?

The actuator’s relevance depends on the specific system it controls and how important it is for the car’s driving. The drivability of a car may not affected by a faulty power window actuator, but by a faulty brake actuator, certainly. To determine whether driving the car is safe, it is best to have a professional mechanic diagnose the problem.

How to Prevent Actuator Clicking?

Often, actuator clicking is the result of normal wear and tear or age-related deterioration of the actuator or other electrical components. In spite of the fact that actuator clicking and other electrical issues cannot be prevented, regular maintenance and prompt repairs can minimize the risk.

The clicking of actuators is a normal part of a car’s operation, and it cannot be prevented since these components engage and disengage to perform specific functions. Many systems inside a car use actuators and their operation accompanied by these clicking sounds. Among these systems are:

HVAC (Heating, Ventilation, and Air Conditioning):

In the cabin, HVAC actuators control the blend of hot and cold air, as well as the direction of airflow. When these actuators adjust the temperature or vents, clicking noises may heard.

Power Locks:

Power door lock systems use actuators to lock and unlock doors remotely or by pressing a button. When the actuators engage and disengage the locks, clicking sounds may heard.

Engine Components:

As actuators adjust valve timing, they can produce clicking sounds as they adjust the timing of the valves.

Other Systems:

Besides power seats and power windows, actuators are also used in various other car systems.

As actuator clicking is inherent to their operation, it cannot prevented without disabling the systems they control. It is not recommended to attempt to prevent the clicking sounds, as this could result in malfunction or reduced functionality of these systems.

To ensure that there are no underlying problems with the actuators or the systems they control, have your car inspected by a qualified mechanic if the clicking noises are excessively loud or unusual. Maintaining and repairing your car regularly can help keep its components, including actuators, in good working order.

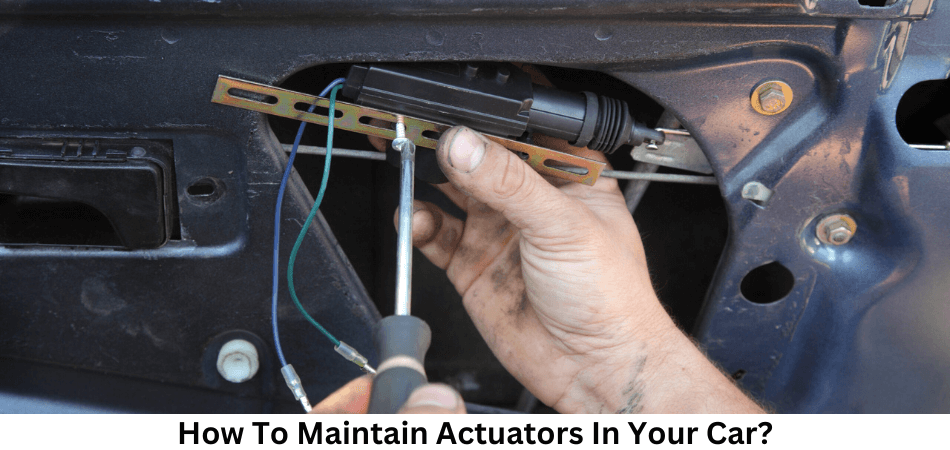

How To Maintain Actuators In Your Car?

The key to maintaining actuators in a car is to ensure that the systems they control are running smoothly and efficiently. The following tips will help you maintain your car actuators:

Inspecting regularly:

Your car’s actuators should inspected periodically. Any actuator-driven system, including HVAC, power locks, and power windows, falls under this category. If you hear or see unusual sounds, check for signs of wear or damage.

Maintain a clean and lubricated engine:

It is possible for dust, debris, and a lack of lubrication to affect the performance of actuators. It may be possible to clean the actuator and apply a suitable lubricant to ensure smooth operation depending on its type and location. Lubrication should used carefully, as some actuators do not require it and excessive lubrication can damage them.

Electrical connections should be checked:

Electrical connections are often found on actuators. It is important to ensure that these connections are secure and clean. It is possible for electrical problems to occur due to corrosion or loose connections.

Functionality testing:

Test the actuator-controlled systems on a regular basis. Make sure doors lock and unlock smoothly, windows move up and down smoothly, and the HVAC system directs air where it should. Address any issues immediately if you notice them.

Recommendations from the manufacturer:

Detailed maintenance recommendations for actuators and systems that they are a part of can be found in your vehicle’s owner’s manual. It is often recommended by the manufacturers to maintain these components in good working order.

Inspecting professionally:

A qualified mechanic should inspect your car if you suspect a problem with an actuator or are not comfortable performing maintenance tasks on your own. Diagnoses and solutions can implemented effectively by them because they possess the necessary knowledge and tools.

Replace Worn Parts:

It is possible for actuators or related components to wear out over time and need to be replaced. It is crucial to replace worn or damaged actuators and associated parts with genuine or high-quality replacements.

How Much Does It Cost To Replace An Actuator?

Depending on the make and model of the automobile, as well as the type of actuator that needs to be replaced, the cost of replacing an actuator can vary greatly. In general, parts and labor can cost between a few hundred dollars and over a thousand dollars.

Depending on the make and model of the car as well as the type of actuator that needs to be replaced, it can take a long time to replace an actuator. Including diagnosis, parts acquisition, and installation, it typically takes between a few hours and a full day.

Can I Fix A Faulty Actuator Myself?

The type of actuator that needs to be repaired and your level of experience determine how difficult it will be to fix it. In some cases, actuator repairs can be done by a knowledgeable DIYer, but in others, specialized tools and expertise are required.

The best way to ensure that the repair is done safely and correctly is to have a professional mechanic diagnose and fix the problem.

Conclusion: Actuator Clicking When Car is Off

A clicking sound from your car’s actuator when it’s off might be normal, related to security features, or indicative of a problem. Whenever the sound seems abnormal or persists, you should seek professional assistance. Maintaining your vehicle regularly and addressing issues promptly can help ensure reliable and safe operation. It’s advisable to consult a qualified mechanic or automotive technician if you’re unsure what’s causing the clicking sound. In addition to diagnosing the issue accurately, they can run diagnostic tests and recommend the necessary repairs or maintenance.

Read our more articles in here..

FAQs

When my car is off, why does the actuator click?

Several reasons can cause actuators to click when the car is off, including residual power, a faulty actuator, or a security system.

When the car is off, do actuators make clicking sounds?

In some cases, residual power in the car’s electrical system can cause actuators to make clicking sounds. Nevertheless, excessive or irregular clicking should be investigated.

Do I have a faulty actuator if I hear a clicking sound?

Listen carefully for the source of the clicking to determine if it is a faulty actuator. A problem with an actuator may be causing the sound to come from a specific door or component.

Is it possible for a security system to cause actuators to click when the car is off?

The car security system may activate actuators to lock or unlock doors, causing clicking sounds when the car is off. For confirmation, check the settings of your security system.

If the clicking bothers me, what should I do?

Consult your car’s manual or a professional mechanic if the clicking noise is bothering you. It can be dangerous to ignore unusual sounds.

If you’re looking for a superior SUV experience, the 2023 Chevrolet Equinox is the perfect vehicle for you. Whatever your needs are, the Equinox can handle it. Prescott Valley Chevrolet customers report the Equinox has superb handling, with a smooth, responsive ride. Additionally, fuel economy is excellent. Yet, the Chevy Equinox Maintenance Schedule is necessary to keep the vehicle running.

Those in the backseat will appreciate the Equinox’s spaciousness. Budget-conscious buyers will appreciate the 2023 Equinox’s affordable price tag. Its turbocharged 1.5-liter four-cylinder engine produces 170 horsepower and 203 lb-ft of torque. If you’re looking for a reliable, comfortable, and stylish SUV, the 2023 Chevy Equinox is the perfect choice.

Maintaining your Equinox at the Prescott Valley Chevrolet dealership is the best way to keep it operating at its best. A few of Equinox’s scheduled maintenance visits highlighted below. So let’s learn more about the Chevy Equinox Maintenance Schedule.

What are the Features of Chevy Equinox?

The 2023 Chevy Equinox is a capable mainstream compact SUV. It comes standard with a variety of infotainment and safety technology, even at the base LS trim level. Aside from its inoffensive design, the Equinox offers generous interior space for passengers and cargo. It’s a lot more fun to drive than it looks. The car’s anemic turbocharged four-cylinder engine delivers only 175 horsepower. Equinox lacks flavor compared to many more flavorful competitors. All these alternatives have more personality and verve than the Mazda CX-50, Honda CR-V, VW Tiguan, and Ford Bronco Sport. But, the Equinox remains one of the best-selling compact SUVs. Read here more.

Engine, Transmission, and Performance

With its sluggish performance and underpowered turbocharged 1.5-liter four-cylinder, Equinox’s turbocharged 1.5-liter four-cylinder won’t impress any fans. Equipped with the optional (and heavier) all-wheel-drive system (front-wheel drive is standard), the Equinox requires a heavy foot to speed up to highway speeds. In spite of its fuel-saving design, the six-speed automatic shifts , but it is reluctant to downshift when extra power needed. We tested an all-wheel-drive Equinox RS trim at our test track, which reached 60 mph in 8.0 seconds.

Equinox’s handling is competent and its steering is accurate and direct. Rougher stretches of road send some unpleasantness into the cabin, especially with the optional 19-inch wheels (17s are standard). Additionally, the Chevy is capable of towing up to 3500 pounds.

Fuel Economy and Real-World MPG

According to the EPA, the front-wheel-drive Equinox will achieve 26 mpg in the city and 31 mpg on the highway. AWD reduces fuel economy by 2 and 1 miles per gallon, . In our real-world fuel-economy test route, we drove a 1.5-liter Equinox with front-wheel drive at 75 mph and it returned 32 mpg.

Interior, Comfort, and Cargo

Equinox’s cabin has a nice design and built with durable materials. There are enough amenities to keep front- and rear-seat passengers happy on longer trips in the spacious interior. While there are plenty of cupholders in the cabin, the most luxurious features are either optional or standard equipment on LT and RS models. Despite some rivals offering more space behind the rear seats, we were still able to fit eight carry-on suitcases. Except for a large center console storage bin, Equinox’s cabin storage is average.

Infotainment and Connectivity

The Equinox’s dash features a 7.0-inch touchscreen that displays Chevrolet’s MyLink infotainment system with its ease of use and speed of response. Bluetooth phone and audio streaming, USB connectivity, and an auxiliary input jack are all standard. Equinox offers 4G LTE onboard Wi-Fi, making it one of the most connected crossovers on the market.

Safety and Driver-Assistance Features

NHTSA gave the Equinox a five-star rating, but the Insurance Institute for Highway Safety (IIHS) did not name it a Top Safety Pick. There are also a variety of driver-assistance technologies available with the compact crossover. Among the key safety features are:

- Automatic emergency braking with pedestrian detection as standard

- With lane-departure warning and standard lane-keep assist

- Cruise control with adaptive settings is available

- Warranty and Maintenance Coverage

Chevy’s basic warranty package is as basic are those of its competitors. Hyundai Tucson and Kia Sportage both offer longer protection plans. One dealer maintenance visit is also free within the first year of ownership, which is a nice perk.

- The limited warranty covers 36,000 miles or three years

- The powertrain warranty covers 60,000 miles or five years

- For the first visit, maintenance is complimentary

What are the Problems with Chevy Equinox?

1.Issues with the Timing Chain in a V6 Engine

A damaged timing chain in a V6 engine is one of the most common problems Chevy Equinox owners face.

combustion engines consist of fixed cylinders and pistons that move. Through the intake valve, fuel and wind mix to form a mixture that passes through the cylinder. Burning fuel and air produce energy once they enter the cylinder.

The combustion cycle releases gases that drive the pistons down the cylinders. In turn, this causes the crankshaft to spin, which raises the pistons again. During this part of the process, burned gases leave the exhaust valve. Both intake and exhaust valves controlled by a camshaft. In order for these valves to open and close at the best time, a timing chain used. Additionally, a timing chain synchronizes the rotation of the crankshaft and camshaft. Intake and exhaust valves close at ideal times when the timing chain is working . Timing chains stretch out, which affects this process.

The vehicle’s internal computer system will sense something is wrong and light up the check engine light. The check engine light may come on when the timing chain stretches or becomes slack due to this reason.

2. Oil Consumption Problems in the 4 Cylinder Engine

Because the Chevy Equinox has a four-cylinder engine, it’s not uncommon for this kind of engine to consume oil . There is one major drawback to four-cylinder engines: they tend to consume a lot of oil compared to engines with fewer cylinders.

As For a Chevy Equinox, GM recommends burning less than one quart of oil every 2,000 miles. A four-cylinder engine in a Chevy Equinox can consume over four quarts of oil every month, according to owners and drivers. There is no doubt that this is higher than what General Motors estimated. Your Chevy Equinox may consume even more oil per month depending on how often you drive it.

3. Oil Leaks Are Another Common Problem with the Chevy Equinox

Whether it’s because of a bad rear main seal or another problem, oil leaks with Chevy Equinoxes tend to happen more than they do with other vehicles.

4. Bad Piston Rings Are Also a Common Issue as well

The fix for a Chevy Equinox that consumes oil like there’s no tomorrow may be as simple as replacing the piston rings. It is possible for excessive oil to seep through piston rings if they aren’t sealing . GM acknowledges that this is a common problem, especially with second-generation Chevy Equinoxes introduced between 2010 and 2017.

According to General Motors, most of the common causes of excessive oil leakage in Chevy Equinoxes explained in a technical service bulletin.

5. Issues with EVAP Codes

When the gas cap on a Chevy Equinox fails, it can cause a whole host of problems. The evaporation emission control system (EVAP) is an important part of the vehicle. It prevents gas fumes from escaping from the gas tank.

Also to keeping your car from smelling of gas outside, the EVAP serves another important purpose. As a result of the EVAP, toxic pollution reduced. An EVAP code will appear in the diagnostic process if the gas cap loosens, wears out, or the purge valve malfunctions.

What is the Chevy Equinox Maintenance Schedule?

Let’s have a look at the Chevy Equinox Maintenance Schedule and necessary services.

7,500-Mile Service

By Chevrolet, you should perform scheduled maintenance on your 2023 Equinox every 7,500 miles. At this first visit, the technicians will check the engine’s oil level and change the oil and oil filter. Despite designed to lubricate and protect engines for a long time, motor oil deteriorates over time. Changing the oil regularly will reduce engine wear .

Whenever you bring your Chevrolet Equinox in for its 7,500-mile service, the technicians will inspect all the features that keep your SUV running , including the brakes and tires. They will check the fluid levels and top them off if necessary. Additionally, they’ll rotate the tires and check the wipers’ condition. During every maintenance visit, these services included, so you can drive your Equinox in safety and comfort.

22,500-Mile Service

It recommended that the passenger compartment air filter replaced besides to regular maintenance. Incoming outside air filtered by this piece of equipment before it enters the passenger cabin through the vents. It’s important to replace this piece of equipment, since it’s filthy and can cause health problems for you and your passengers.

45,000-Mile Service

To keep the engine running , the air filter needs to replaced after 45,000 miles. Low fuel economy, poor engine performance, and weak acceleration are all signs that the air filter needs to replaced. To keep the engine components running, the service technicians will also replace the transmission fluid.

60,000-Mile Service

Besides to the usual services, replace the spark plugs and inspect the spark plug wires during this mileage interval. By performing this service, you can be sure that you will be able to start your car every time you turn the key.

90,000-Mile Service

It’s 90,000 miles and your car is running great, so it’s time for a comprehensive inspection to ensure that continues in the future.

All your car’s parts need to be in good condition to keep functioning for the next 90,000 miles during this inspection and service appointment. This includes all the services between the 7,500- and 60,000-mile service intervals. Check the tread depth of your Chevy Equinox tires to make sure they don’t exceed 4/32″. Consider replacing your vehicle’s tires if this is the case.

100,000-Mile Service

To reduce fuel economy, poor performance, and hard starts, the spark plugs will replaced after 100,000 miles.

150,000-Mile Service

A flush and change of the engine coolant will performed at 150,000 miles. During the winter and summer, this fluid prevents the engine from freezing and overheating. Another reason to change the coolant at this point is that old coolant cannot protect the cooling system from rust. During the service, the technicians will also check the coolant hoses for wear and leaks. If necessary, they will replace the drive belts as well.

By taking care of these service items, you will ensure your Equinox runs properly and for years to come.

How Often Should You Service Your Chevrolet Equinox?

If you want your car to last, make sure it serviced on time and according to the proper schedule. Also to preventing more extensive problems in the future, taking your car in for service as recommended by the manufacturer means you’ll save money on car repairs and get to drive your car longer. In your vehicle’s manual, you can find the Chevrolet Equinox maintenance schedule to ensure proper service performed. To keep your Chevrolet Equinox in top shape and safe to drive, you must keep up with all service intervals.

What are the Additional Maintenance / Care for your Chevrolet Equinox?

Earlier you have learnt about the Chevy Equinox Maintenance Schedule. However, apart from Chevy Equinox Maintenance Schedule there are some additional maintenance too. Read to learn more.

Alignment

- For your tires to perform at their best, alignment is crucial.

- You may need to adjust your alignment if you notice your vehicle pulling one way or the other as you drive.

Batteries

- During engine start-up, the battery supplies energy to the vehicle.

- A great battery with full cranking power can prevent breakdowns and failures to start your vehicle. The Reserve Capacity (RC) is also important due to additional electrical accessories like on-board computers and navigation systems.

Brakes

- To drive safely and successfully, you must have good stopping power. In addition, it’s important to know if your brakes are working properly when you need to stop.

- A chirping, grinding, or squealing noise or difficulty stopping the vehicle are signs of brake wear.

Fluids

- In order to maintain optimum performance, you should maintain adequate fluid levels in your vehicle.

Hoses

- Maintaining the condition of hoses such as heater and radiator hoses is important.

- A worn, cracked, soft, or blistered hose is a sign of wear.

Lights

Make sure your headlights are bright and work properly when there limited visibility.

Multi Point Vehicle Inspection

- Invest in a multi-point vehicle inspection to protect yourself and your investment. Dealers can examine critical systems and inform you when they may need to repaired. Many components are also checked visually.

- The inspection includes a check of your tires, brakes, belts, hoses, lights, and fluids.

Tires

- The tires on your vehicle are what keep it moving, so we make sure they are properly aligned, balanced, and in top condition. Tire rotation recommended every 7,500 miles or 12,000 kilometers.

- Your tire needs replacing if: three or more tread wear indicators are visible around the tire; the cord or fabric is visible through the rubber; or the tread or sidewall cracked or cut.

Windshields

- Take advantage of the best view of the road. Clean and scratch-free windshields are essential for safety, appearance, and optimum performance.

- Scratches, cracks, wind noise, or water leaks are all signs of wear.

Wiper Blades

- Ensure your wiper blades are in good condition so you can see clearly through your windshield.

- Rubber that worn or split may show signs of wear, such as streaks or skipping across the windshield.

What are the Pros and Cons of Chevy Equinox?

Pros of Chevy Equinox

- Welcoming Interior

As a result of the Equinox’s top-of-the-line Premier trim, its interior was both well-equipped and enjoyable to be in. The cabin features a stylish two-tone design and excellent materials quality, as well as niceties such as a heated steering wheel, hands-free power liftgate, and heated front seats on the Premier trim.

- Easy Controls

Depending on trim, the Equinox comes with either a 7- or 8-inch touchscreen mounted high in the center of the dashboard. In addition to accommodating convenient physical controls for audio and climate, the system responds quickly and has a simple menu structure.

- Room for the (Small) Gang

Even though some others in the category are more spacious, the cabin offers enough legroom and headroom for adults front and rear. It’s easy to install car seats with Latch anchors, and the seat belt stalks are tall enough to connect easily with booster seats. The cargo space is likewise adequate, if not class-leading, and a handy underfloor storage area keeps small items contained.

- Budget Friendly, With a Catch

Pricing is one of the areas where Equinox has an edge over some competitors. Base 2023 Equinox models with front-wheel drive start at $27,995 (including destination) – significantly less than Honda CR-Vs or Toyota RAV4s. It’s still a bit more than a Hyundai Tucson, and all of these competitors offer more standard safety features.

Cons of Chevy Equinox

- Powertrain Problems

An automatic transmission and a turbocharged four-cylinder engine provide 175 horsepower. In addition to not being particularly peppy nor refined, the engine is slow to respond from a stop and has little reserve power for passing and merging. Additionally, the engine contributes to an already noisy cabin, and the automatic stop-start system is anything but smooth. When the SUV started, it automatically turns on again.

- Disappointing MPG

As a result of its lackluster performance and stop-start system, the Equinox is not particularly fuel-efficient. According to the EPA, base models with FWD achieve 26/31/28 mpg city/highway/combined, which is less than similar versions of the CR-V, Tucson, and RAV4.

- Noisy Cabin

Compared to its competitors, Equinox’s cabin is louder due to wind, road, and engine noise. It is arguably the engine that is the worst offender, exhibiting a lack of refinement that is not only unpleasant to listen to, but also causes vibrations in the steering wheel and accelerator pedal that only worsen with speed.

- Rough Rider

In addition to its ride and handling, Equinox is also behind its competitors. When compared to the best in the category, which offers either a comfortable ride or sporty handling or a combination of both, the Equinox is just rough and unrefined. There is a lack of composure throughout the cabin as it shakes and bounces over road imperfections.

How Reliable is The Chevrolet Equinox?

Chevrolet Equinox’s reliability can vary depending on factors such as maintenance, usage, and model year. In general, the Chevrolet Equinox considered a reliable compact SUV, but there can be differences between model years and models.

On highways and in cities, the Chevrolet Equinox offers a solid handling experience. It is a smooth and comfortable drive. There is a good grip on the road by the vehicle. The fuel economy is one of the best in the class for a compact SUV. A segment-leading 39 MPG achieved by the 2018 Chevrolet Equinox Diesel.

As a result of Equinox’s seat height, drivers have excellent forward visibility. Longer drives are more comfortable since there is ample support. In terms of driving comfort, the Chevy Equinox is a very comfortable vehicle. As well as offering a wide range of powertrain options, the car meant to provide comfort and convenience for its occupants. Long journeys made more comfortable with bucket seats.

Although Chevrolet Equinox models have generally had a good reputation for reliability, individual experiences may vary. Consider the vehicle’s maintenance history before making a purchase, and have a trusted mechanic inspect the vehicle if you can. A reputable dealership may also offer certified pre-owned options with warranties and comprehensive inspections, providing additional peace of mind.

Conclusion: Chevy Equinox Maintenance Schedule

Now you have some idea about the Chevy Equinox Maintenance Schedule. Chevrolet Equinox has been a compact SUV in its lineup for many years. For individuals and families seeking an affordable compact SUV with decent interior space and features, the Chevrolet Equinox is a good choice. In order to ensure a vehicle meets your expectations and needs, you should research the exact model year and trim level you’re interested in. For the latest information on the vehicle’s performance, reliability, and features, consider driving it and consulting reviews.

FAQs

Does the Chevrolet Equinox come with both front-wheel drive (FWD) and all-wheel drive (AWD)?

In addition to FWD and AWD configurations, the Chevrolet Equinox comes in a variety of trim levels and engine choices.

How many seats does the Chevrolet Equinox have?

There is a standard seating capacity of five passengers for the Equinox, but some models offer the option of a third-row seat to accommodate seven passengers.

Is the Chevrolet Equinox equipped with any notable safety features?

Typical Chevrolet Equinox safety features include lane departure warning, forward collision alert, automatic emergency braking, and more. Depending on the trim level, some of these features may be standard or optional.

How much can the Chevrolet Equinox tow?

Equinox’s towing capacity varies based on engine and drivetrain configuration. The towing capacity ranges from 1,500 to 3,500 pounds, depending on the model year and configuration.

How fuel-efficient is the Chevrolet Equinox?

It depends on the engine choice and driving conditions to determine the fuel efficiency of the Equinox. The compact SUV segment known for its competitive fuel economy.

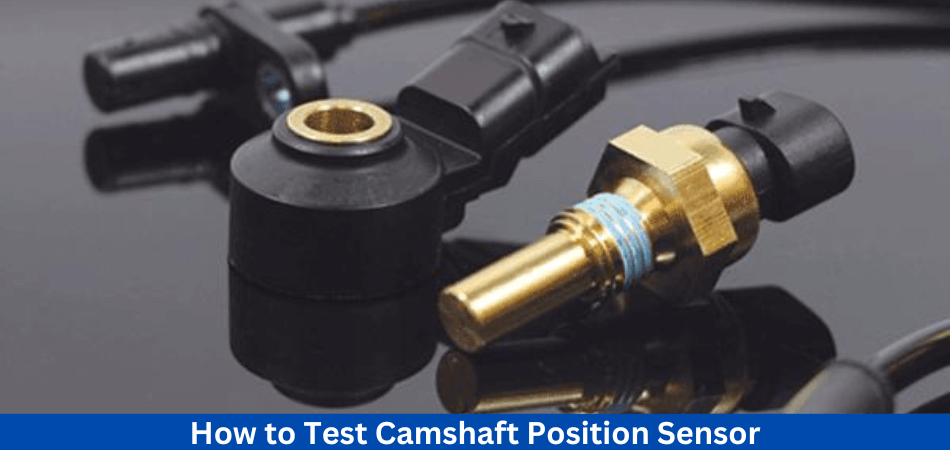

Crankshaft and camshaft position sensors make the rotation of a vehicle’s engine possible. When a sensor malfunctions, a car won’t start; it would make noise, but won’t move. The engine may lose power, misfire, or not spark while starting. Cars can be driven with faulty sensors in many cases, but they shouldn’t as it leads to more danger. Without treatment, you will have to pay for expensive repairs, and your engine may suffer permanent damage. So, How to Test Camshaft Position Sensor?

The camshaft position sensor (CMP) can be checked for functionality and correct operation by checking its functions. The symptoms of malfunction show a total failure of the sensor or its unstable operation, and a multimeter or diagnostic scanner is needed for an accurate diagnosis. It is rare for the sensor itself to fail, but its wiring and plug require attention. In this article, we’ll briefly learn about everything about Camshaft Position Sensor including, How to Test Camshaft Position Sensor.

What Is a Camshaft Position Sensor?

Camshaft position sensors (CMPs) track and send information to vehicle ECMs/PCMs about the actual position of an engine’s camshaft. As a result, this information becomes crucial in determining the positions. Because intake and exhaust valves are throughout both engine banks, since lifters/pushrods correlate with cam/valve timing.

The timing of an engine’s ignition system and fuel injectors is dependent on its camshaft timing. It would be impossible to regulate injector pulse timing or spark advance without such feedback. Additionally, implementing such technology as variable valve timing between banks 1 and 2 would be a pipe dream. A tone ring positioned at one end of the camshaft position sensor captures the signal from the camshaft position sensor, which operates on magnetism.

An engine’s management software receives feedback via a waveform signal generated by the teeth of the tone ring as the camshaft spins. Learn more here.

What are the Types of Camshaft Sensors?

Generally, camshaft position sensors come in two types:

1. Magnetic type or variable reluctance: There are two wires on this type of sensor, which makes it easy to identify. There is an alternating current (AC) sine wave signal produced by the magnetic type.

2. Hall effect type: In this type, there are three wires: one for the reference signal or power, one for the ground, and one for the signal voltage.

Identify the type of sensor you have in your system. There may be a third shielded wire on some magnetic types that helps cancel noise. Consult your vehicle’s service manual if necessary.

What are The Functions of the Camshaft Position Sensor?

In order to better understand how the camshaft position sensor works, let’s look at an example. The camshaft opens the engine valves when an internal combustion engine is started.

As a result, air and fuel directed into the combustion chamber by the engine control module. Then, the valves closed so the piston could begin compressing the air and fuel.

Power produced when the engine control module ignites the combustion process to drive the piston down. Then it reaches its highest point. By opening the exhaust valves, the camshaft permits the piston to return to its original position. After that it release exhaust gases from the exhaust manifold.

The camshaft position sensor and other components also contribute to combustion in an engine.

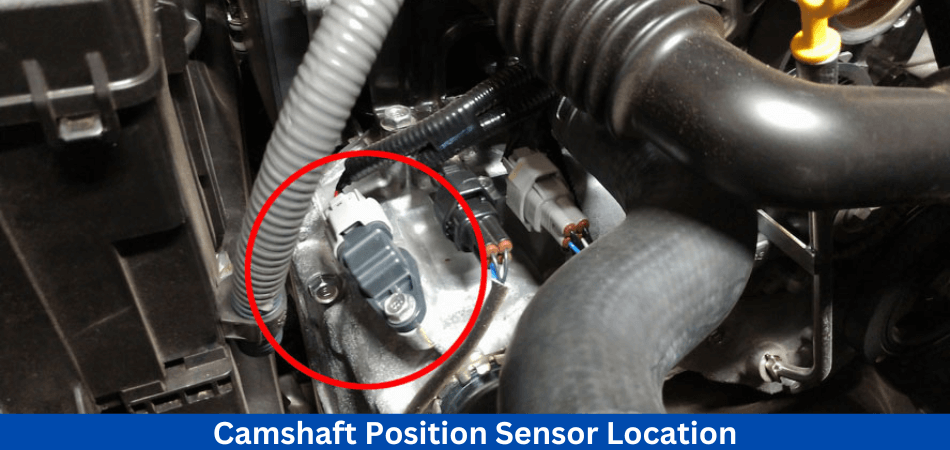

Where Is the Camshaft Position Sensor Located?

The exact position of an engine’s camshaft position sensor varies from vehicle to vehicle. Depending on the engine, the sensor may be mounted directly within the unit’s front timing cover. In some vehicles, this sensor is mounted on the valve cover or cylinder head.

If you are unsure about the exact location of your vehicle’s camshaft position sensor. Then consult your factory-specific service and repair manual.

What are the Symptoms of a Faulty Camshaft Position Sensor?

There are a variety of secondary symptoms associated with a faulty Camshaft Position Sensor, some of which can be quite troubling. When diagnosing an issue of this type, recognizing these symptoms can be invaluable.

There are several common issues associated with a faulty or failing camshaft position sensor.

1. Illuminated Check Engine Light

Most of the time, a faulty camshaft position sensor will illuminate the check engine light on a vehicle. When a vehicle’s PCM logs one or more timing-related diagnostic trouble codes, this occurs.

2. Starting Difficulties

A vehicle won’t start without a valid timing signal from the camshaft position sensor. Vehicles may only start intermittently or fail to start altogether when this happens.

3. Stalling

For some vehicles, an accurate camshaft position sensor signal required to continue operating. The engine will likely stall if this signal is lost, even for a moment.

4. Erratic Idle

A vehicle’s camshaft position sensor may begin to malfunction when the engine idles at first. Any signal data presented to the vehicle’s ECM/PCM is relatively inaccurate.

5. Hesitation/Loss Of Power

An engine with a failing camshaft position sensor might also appear low on power, hesitate under load, or lurch or jerk when accelerating. The ECM/PCM of an engine receives inaccurate or inadequate feedback.

6. Reduced Fuel Economy

To facilitate efficient fuel delivery and spark timing, internal combustion engines require accurate camshaft position sensors. When the sensor fails, fuel is often consumed excessively, resulting in reduced fuel economy and increased exhaust odor.

7. Failed Emissions Test

A malfunctioning camshaft position sensor can cause state-mandated emissions tests. Even short periods of overfeeding can result in overly rich exhaust emissions.

What Causes the Camshaft Position Sensor to Fail?

There are a number of reasons why a vehicle’s camshaft position sensor can fail. Exposure to prolonged periods of extreme heat is one of these causes. Camshaft position sensors often fail following instances of engine overheating. Which explains the higher-than-normal frequency of such failures.

Premature fatigue and failure can also caused by contamination from oil, coolant, or other chemicals. Sensor wiring receptacles or other wiring can contaminated by this contamination. As a result, the insulation material that protects the wiring of the circuit can break down.

It is also possible for this sensor to damaged by road debris when it is hit by an impact. If not protected by a suitable undercover, debris can strike timing cover-mounted camshaft position sensors.

Can You Drive With a Bad Camshaft Position Sensor?

In most cases, it is not recommended to drive with a bad camshaft position sensor, unless it is absolutely necessary to reach a safe destination for repairs. Such failures are often accompanied by a variety of drivability-related symptoms.

If one drives in this manner, one may end up stranded on the side of the road with little recourse.

It is always advisable to replace a faulty sensor at the earliest opportunity. Since the camshaft sensor in question continues to deteriorate, this prevents further hardship. A trusted service center should contacted as soon as possible if you do not feel comfortable doing the repairs yourself.

Why Should You Check Crank Sensors Regularly?

Crankshaft sensors convert mechanical energy into electrical signals that power ignition and fuel injection systems in engines. Multimeter testing ensures that the crankshaft sensor is functioning and sending accurate information to the vehicle’s computer.

Misfires, poor power, stalling, hard starting in cold weather, and reduced acceleration can caused by faulty crank sensors. It may be possible to identify problems with a crank sensor that might otherwise be difficult to diagnose without testing it. By checking your crankshaft sensor, you can extend the lifespan of your vehicle. Read more to learn about How to Test Camshaft Position Sensor.

What You Need To Know Before Testing Camshaft Position Sensor?

It is essential to ensure that all safety protocols have followed before using a multimeter to test the crankshaft position sensor. Be sure the vehicle parked safely, level, and that the negative battery cable disconnected before beginning any tests. Digital multimeters should also used with extreme caution. Since incorrect readings can damage electrical components or even short-circuit them.

Also, it’s important to know where the crankshaft sensor located within the engine and how it works. On either inline or V engines, these sensors are generally mounted near the flywheel, so some engine disassembly required to reach them. The type of crankshaft position sensor installed in your vehicle is also crucial. Many modern cars use either hall effect or variable reluctance sensors.

Then, using a multimeter, you can test the crankshaft position sensor once all safety precautions have been taken.

How to Test Camshaft Position Sensor?

Now let’s learn the steps of How to Test Camshaft Position Sensor.

1. Testing a Magnetic type CMP Sensor

The magnetic-type CMP sensors produce their own AC (sine wave) signal. If you want to test AC (alternating current) voltage, you will need a digital multimeter (DMM).

To prevent the engine from starting, disable the ignition system or fuel system. A jumping wire can used to ground the ignition coil and high tension wire from the distributor cap. Metal brackets or bolts can used on the engine for this purpose. You can also prevent the engine from starting by removing the fuel pump fuse. Refer to your vehicle’s manual if necessary.

- If you have a manual transmission, set it to Neutral or Park.

- Be sure to engage the emergency brakes.

- Make sure the CMP sensor unplugged.

- DC voltage should be set on your multimeter.

- If the ignition is on but the engine is off, check for voltage at the harness connector. The terminal may have around 1.5 volts depending on your particular model. You should consult the owner’s manual of your vehicle.

- You can now read AC voltage with your DMM meter.

- Make sure your DMM leads connected to the pins on the sensor terminals.

- For a few seconds, have an assistant crank the engine.

- You can check your multimeter’s voltage by reading it.

- Your results should compared to the specifications in your repair manual.

2. Testing a Hall Effect Type CMP Sensor

A Hall effect sensor produces a squared, digital signal representing the highest and lowest voltages.

- Park (automatic) or Neutral (manual) your transmission.

- Be sure to engage the emergency brakes.

- Stop the engine from starting by removing the fuel pump fuse. You may need to consult the owner’s manual of your vehicle if necessary.

- Make sure your DMM is set to DC volts.

- Connect your DMM’s ground lead (black) to battery negative, the post with the negative (-) sign. And back probe the power wire on the harness connector with the DMM’s red lead.

- For a few seconds, have an assistant crank the engine.

- A DMM reading of about 5 volts should be obtained.

- Back probe the harness connector’s ground wire with the red lead of your DMM. Connect the ground (black) lead of your DMM to the negative lead of the battery.

- Crank the engine for a few seconds with an assistant.

- A voltage reading of about 0.1 or 0.2 volts is normal.

- You can now back probe the signal wire on the harness connector with the red lead of your DMM. Make sure the ground (black) lead of your DMM connected to the negative terminal of your battery.

- Start the engine briefly with the assistance of an assistant.

- In the range of 0 to 5 volts you should get a fluctuating voltage reading.

- There are some errors with your signal values, but the power and ground values are fine, so replace the CMP sensor. If necessary, consult the electrical value specifications in your vehicle repair manual.

How Much Voltage Should a Crank Sensor Have?

Earlier you have learnt about How to Test Camshaft Position Sensor. Now lets move to the voltage section. It depends on the type and make of the vehicle and what voltage the crank sensor should have. A multimeter generally measures between 0.1 volts and 5 volts when testing crankshaft sensors. Crankshaft sensors operate on analog signals that fluctuate with engine speed. You’ll need to adjust your multimeter settings accordingly in order to accurately measure this signal.

If you’re not sure which setting to use, consult your vehicle’s repair manual or ask an experienced mechanic. You should check the voltage reading at idle speed after you’ve set up your multimeter correctly. You should see a reading between 0-2.5 volts, depending on your vehicle’s make and model. A crankshaft sensor that reads above or below this range should be replaced.

While the engine is running at higher speeds, you should also check the voltage. If the reading is outside of this range, the crank sensor needs to be replaced. The reading should usually be between two and five volts. Besides, if your vehicle has other electrical issues, such as a malfunctioning alternator or spark plugs,. Then the readings may not be accurate, and further diagnostics may required.

Can You Test a Crank Sensor With Oscilloscope?

Using an oscilloscope, you can test the crankshaft sensor. An oscilloscope measures electric signals over time.

With the crankshaft sensor connected, it displays voltage changes as the engine runs and the crankshaft rotates in real time. Using this information to diagnose or tune the sensor can provide valuable insight into its performance.

An oscilloscope can used to test your crankshaft sensor. Connect one probe from the oscilloscope to your engine’s ground point (the battery negative post is ideal), and the second probe to the crank sensor’s terminals. Observe the oscilloscope waveform after starting your engine. Voltage spikes and drops should not occur intermittently on the sensor’s waveform. You may need to conduct a further investigation if you notice any irregularities.

If you plan to use an oscilloscope to test your car’s crankshaft sensor. Not only should you check your car’s service manual, but also your vehicle’s manual may contain specific information about how to do so. Moreover, if you are unfamiliar with oscilloscopes, it is best to leave this task to a qualified mechanic with experience reading waveforms.

What If My Crankshaft Sensor Passes the Test?

You may not be experiencing a malfunction due to the crankshaft sensor if you pass the test. The problem may also be caused by other sensors, spark plugs, or wiring around the area. A professional diagnostic might be a good idea if you can’t find anything wrong with those components either. In some cases, a technician can diagnose the problem and fix it.

In some cases, crankshaft sensors that pass the test but still have problems with your vehicle’s performance are faulty or malfunctioning. It may be necessary to replace the component with a new one in this case.

No There’s no denying that crankshaft sensors are vital components of a vehicle. Maintain it in good working condition by testing it regularly and replacing it as needed to ensure optimal performance. By following these steps, you can avoid costly repairs in the future.

How to Replace the Crankshaft Sensor?

Once the crankshaft sensor has been tested and determined to be faulty, it needs to be replaced. There may be several steps involved in this process, depending on your vehicle. A crankshaft sensor is usually accessible by removing components and disconnecting wiring harnesses.

Disconnect any associated wiring after you have located the component and unbolted it from its mounting bracket. After removing the old crankshaft sensor, install the new one in reverse order, ensuring all connections secured.

Test that everything is working as expected by starting the car. After checking everything out, reinstall any removed components and reconnect any disconnected wiring harnesses. Now that your crankshaft sensor has replaced, it should work properly.

If you are replacing the crankshaft sensor, follow all safety instructions properly. By doing so, you will ensure you drive safely and your car runs optimally.

What is the Replacement Cost of a Camshaft Position Sensor?

Depending on the make and model of the vehicle, camshaft position sensor replacement can cost varying amounts. As a result, the costs of parts, labor, and labor hours required to complete such repairs differ significantly.

In spite of this, the cost of such repairs tends to be predictable. Typically, replacing the camshaft position sensor on a vehicle costs between $100 and $250. Purchasing a replacement sensor itself will cost around $30-$120. while installation-related labor will cost another $70-$130. A shop supply charge may incurred in certain cases.

Additional Tips and Advice

It is important to remember that crankshaft position sensors are delicate when testing them with a multimeter. When you handle them incorrectly, you risk damaging the sensor and causing bigger problems. You should follow the following advice to ensure that your tests are accurate and to avoid damaging the sensor:

Make sure to use a Current Limiting Resistor (CLR) when connecting the crankshaft position sensor to power sources. It prevents the sensor from being overloaded with voltage or current that could damage it.

Before performing any tests on the crankshaft position sensor, make sure all connections are secure. Sensors can be permanently damaged by loose connections leading to inaccurate readings.

When testing the crankshaft position sensor, make sure your multimeter is set to the appropriate range. It is important to adjust the settings and ranges of multimeters carefully to get accurate readings.

Make sure you have experience with electrical work before attempting to repair or replace a crankshaft position sensor. It is important to handle these sensors with care in order to avoid any potential damage.

Conclusion: How to Test Camshaft Position Sensor

Now you have a clear idea of How to Test Camshaft Position Sensor. In conclusion, testing a crankshaft sensor with a multimeter is a relatively easy process. Following these steps will help you determine if the sensor is functioning properly quickly and accurately. Keep yourself safe when working with electrical components by taking safety precautions. Regularly testing your crankshaft sensor will enable you to identify potential problems. For many years to come, this will help preserve the performance of your vehicle.

Read more of our articles here.

FAQs

What is the appropriate ohm value for a crank sensor?

Different models and makes of crankshaft position sensors have different resistances. A resistance of 500-1500 ohms is generally recommended. If you want to be sure, consult the service manual for your vehicle.

How does a faulty crankshaft sensor affect the engine?

Several engine problems can caused by a faulty sensor, including misfires, stalling. Also, it can cause fault codes to appear in your engine control module, resulting in an illuminated check engine light.

How safe is it to use a multimeter to test a crankshaft sensor?

You should always take the necessary safety precautions. Ehen testing your crankshaft position sensor with a multimeter. It is also important to read and follow the instructions for the multimeter you are using, as improper use could result in electric shock. For help using a multimeter safely, contact a qualified mechanic.

How can I determine if my crankshaft sensor is working correctly?

You should test your crankshaft position sensor with a multimeter to the instructions. A qualified mechanic can assist you if you’re not sure how to do this. A malfunctioning sensor can also be visually checked for signs of wear or damage.

When should I test my crankshaft position sensor?

You should perform regular maintenance checks on your vehicle’s crankshaft position sensor. To ensure optimal engine performance and reliability. Once a year or every 10,000 miles, test it with a multimeter according to the manufacturer’s instructions. The sensor should replaced as soon as possible if any issues found during the test.

There is nothing that lasts forever, and your transmission is no exception – especially if it is automatic. A transmission in a car will last up to 200,000 miles on average. Therefore you might need to rebuild it. But How long does it take to rebuild a transmission?

When your car has reached 200,000 miles, or if you are considering having it rebuilt, you might wonder how much it will cost and how long it will take. This article will cover How long does it take to rebuild a transmission, including it’s pros and cons. Lastly, we’ll discuss if the transmission rebuild is worth the money.

What is a Transmission Rebuild?

A transmission rebuild involves inspecting and replacing faulty transmission components with new ones. Yet, it’s not as easy as it sounds since it’s one of the most demanding automotive repair procedures.

You won’t be able to handle this on your own, and picking the right mechanic is important. When it comes to automatic cars, the transmission contains a lot of moving parts. In order for the rebuilt system to work, these sensitive parts must replaced.

Learn more at here.

How to Tell That Your Transmission Needs Repairs?

There is no light on the transmission of a vehicle, despite it being a vital component.

But, you can detect transmission issues before you become stranded with a car that won’t move. You can find them here:

1. The check engine light:

There are many problems that can indicated by this light, such as transmission problems. This light should never ignored, and you should visit a mechanic as soon as possible. A vehicle’s warning light is only illuminated when something serious is likely to happen. If you think there is a problem, you must have it checked as soon as possible.

2. Fluid Leaks:

You can drive either an automatic or a manual. Transmission fluids must lubricated, and leaks can cause a problem. You should check your transmission if you see brown spots on your parking space or if your transmission fluid is low.

3. Sluggish acceleration:

Generally, expert drivers can tell if their cars are malfunctioning. It’s likely that you have a transmission issue if you feel like your car is not accelerating. Check it out to save money on repairs.

4. Sounds:

The transmission may be malfunctioning if you hear unusual sounds, especially during shifting.

If you hear clunking, squealing, rattling, or slight humming, your transmission is faulty. The sooner you get things under control, the lower your costs will be.

What You Should Know Before a Transmission Rebuild

You may need to consider a transmission rebuild if your vehicle’s transmission shows signs of wear or injury. During transmission rebuilding, the transmission disassembled, inspected, and any damaged or worn parts replaced. If you decide to rebuild your transmission, here are some things you need to consider:

Cost:

Rebuilding a transmission can be costly. Often costing several hundred to several thousand dollars. A lot depends on how your vehicle was built and model, where the transmission was damaged, and the cost of replacement parts.

Time:

In some cases, transmission rebuilds can take up to a week or more to complete. This depends on the difficulty of the rebuild and availability of replacement parts.

Quality of Parts:

The quality of replacement parts is crucial when it comes to transmission rebuilds. Rebuilding a transmission requires high-quality parts to ensure long-term durability. The mechanic may use low-cost parts in an attempt to save money. But this can result in future problems and potentially more expensive repairs.

Warranty:

Any transmission rebuild work performed by a reputable mechanic will be covered by a warranty. Before accepting the work, ask about the warranty.

Maintenance:

To ensure the longevity of a rebuilt transmission, proper maintenance is essential. If you need to change transmission fluid or perform other maintenance, follow the manufacturer’s recommendations.

Experience:

The transmission rebuild should be performed by an experienced, qualified mechanic. Choose a mechanic who has experience rebuilding transmissions for your vehicle’s make and model and who has a track record of success.

While transmission rebuilding is a time-consuming and costly process, it is crucial for ensuring your vehicle’s longevity and performance. It is important to choose a reputable mechanic and use high-quality parts, as well as maintain the rebuilt transmission properly to ensure its longevity.

What are the Processes to Rebuild Manual Transmission?

- Make sure your problem is not limited to your clutch, and rebuild the transmission if necessary.

- Remove the transmission from the vehicle.

- Check the clutch disc, pressure plate, flywheel, and other connected components.

- To restore clutch function, replace any cracked elements.

- Reinstalling the transmission is time-consuming. If necessary, top up the transmission fluid.

- Make sure the clutch installed and adjusted by performing a lift check.

- It will be ready to drive several miles after being street-tested to confirm optimal transmission and clutch operation.

What are the Factors Affecting How Long a Transmission Rebuild Will Take?

A Busy mechanic shop – It’s said that a busy mechanic shop is a good one. And often this can be true. The mechanics will be in high demand, so it may be difficult to get a fast turnaround if they are good.

There is also the possibility of the opposite happening. Due to the mechanics’ poor skills, anything they do takes a long time. Whatever you do, don’t expect to get your car back the next day if you have the transmission rebuilt.

Parts availability –

Most part suppliers will carry the most common transmission parts if you drive a popular type of vehicle. It’s likely that you’ll only need to make a phone call to get things like a master transmission rebuild kit, solenoids, and gaskets. A gear or pump can found from a salvage yard if a hard part needs to replaced. The parts required to rebuild your transmission may take longer to get if your vehicle is a bit more unusual.

Installing and removing the transmission –

On some vehicles, removing the transmission takes only a couple of hours. Besides, it can take as long as 4-6 hours to remove the old transmission from more complicated vehicles. After the transmission has been rebuilt, it must be reinstalled.

Rebuilding the transmission –

Transmissions can dismantled, diagnosed, and rebuilt in 3-4 hours by an experienced transmission rebuilder. It can be time-consuming and distracting for them to jump from one job to another in a busy shop. Additionally, some automatic transmissions are more complex than others. , which takes more time.

As soon as the rebuilt transmission has reinstalled, the vehicle needs to tested to ensure that it is working . It may be necessary to remove and disassemble the transmission if it doesn’t work . Even more time will required for this.

Rebuilding a transmission takes time. , it’s not a good idea to be without your vehicle too long. In the same vein, you don’t win a mechanic by rushing the job and not doing it right.

How Long Does It Take To Rebuild a Transmission?

So the question is How long does it take to rebuild a transmission? A qualified shop can rebuild a car transmission in 1-2 days, and a truck transmission in 2-3 days.

There are many factors that determine how long it will take to rebuild your transmission:

- Transmission complexity

- Parts and tools are available

- Difficulty in removing and reinstalling

- Mechanic’s level of experience

The rebuilding of most passenger vehicle automatic transmissions will take up to two days 9 times out of 10. There is a good chance that your manual transmission will be rebuilt within the same day if your car built before 2010.

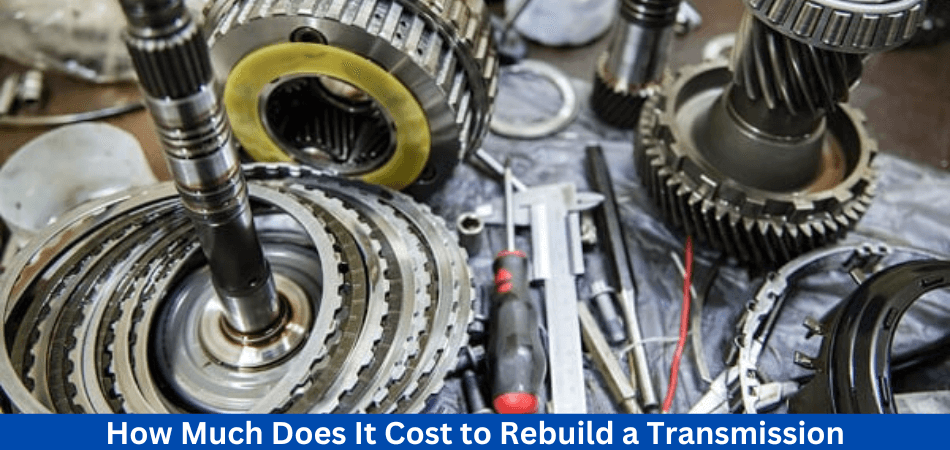

How Much Does It Cost to Rebuild a Transmission?

Okay, so we’ve discussed how long it will take a transmission to be rebuilt, but what about the cost?

It depends on the type of transmission and the year, make, and model of your vehicle and what it will cost to rebuild a transmission. A transmission in an older car is generally much cheaper to rebuild than one in a new car with complicated internals.

In general, rebuilding a car transmission costs between $1,500 and $4,000, and rebuilding a truck transmission costs between $2,500 and $6,000. It depends on the specific transmission, the number of parts that need to replaced, and how much labor needed.

Major transmission damage (broken teeth on many gears, etc.) will be more expensive to rebuild than minor damage (like blown seals).

By transmission type, here’s how much it costs to rebuild a transmission:

- Manual Transmission – $1,500 to $2,500

- Automatic Transmission – $2,500 to $4,000

- CVT Transmission – $3,000 to $5,000

- Diesel Transmission – $3,500 to $6,000

The average cost of rebuilding an automatic transmission is higher than that of rebuilding a manual transmission.

Different Expenses to Rebuild a Transmission

There are several factors that can affect the specific costs associated with replacing or rebuilding a transmission. Among the most important expenses are:

For transmission repairs or rebuilds, labor costs can be a significant part of the cost. Labor costs affected by many factors, including the expertise and experience of the mechanic performing the repair.

The cost of replacement parts can vary significantly depending on the type of transmission and the amount of repair needed. Some components are very expensive, while others are quite affordable.

- The repair may must additional expenses for fluids and supplies as well as replacement parts.

- For diagnosing specific transmission issues, it may be necessary to charge a diagnostic fee.

- There may be additional costs associated with towing a car to the shop for repairs if it can’t be driven.

- According to the regional and local laws, taxes, and fees may increase the cost of the repair.

Before agreeing to any transmission work, ask the repair shop for a detailed estimate. This can help you comprehend the exact costs involved and help you decide whether to proceed with the repair or consider other options. If you’re looking for a repair shop, it’s important to choose one that has a good reputation and consider factors such as warranties and guarantees.

What are the Time Differences Between Manual vs. Automatic Transmission Rebuilding?

How long does it take to rebuild a transmission? Because it requires the removal and of the transmission, replacement, or repair of worn or damaged parts. And assembly and installation of the transmission. Although the rebuild process is similar for manual and automatic transmissions. There are some key differences that may affect the rebuilding time.

A manual transmission has fewer parts than an automatic transmission, so it can be rebuilt more quickly. Transmissions with automatic transmissions need extra and inspection. Because hydraulic pumps and torque converters are more complicated.

The labor cost of rebuilding an automatic transmission may be higher than that of rebuilding a manual transmission. Because of the longer rebuilding process and the greater specialized knowledge required.

Manual transmission parts may be more readily available than automatic transmission parts. This depends on the make and model of the vehicle. Rebuilding can be slowed down if certain parts need to be ordered or made custom-made.

On Rebuilding a manual transmission can take between 4 and 10 hours. While rebuilding an automatic transmission can take between 6 and 20 hours. It may take longer depending on the make and model of the vehicle, the damage, and the skill level of the mechanic.

If you’re considering a transmission rebuild, it’s important to find a reputable mechanic with experience working on your vehicle’s transmission. A successful rebuild can be ensured and the risk of future problems can be reduced.

How Long Does a Rebuilt Transmission Last?

Rebuilt transmissions should last just as long as new or remanufactured transmissions – around 100,000-200,000 miles. It is likely that the transmission will last at least 40,000 miles if the rebuild was done on the cheap and not all worn parts were replaced.

Your transmission’s number will change depending on how well you maintain it and whether the mechanic rebuilt it correctly.

If you tow a trailer every day and drive a lot, you can expect the transmission to last less than 200,000 miles. Alternatively, if you drive your car only on weekends and take good care of it, the transmission may last much longer than 200,000 miles.

What are the Pros and cons of Rebuilding a Transmission?

It is a good idea to rebuild your car’s transmission (if it is in good enough condition to be rebuilt) when it comes to reliability and longevity. Rebuilt transmissions can last another 100,000 miles or more if they are done well by a professional. Additionally, since the mechanic will disassemble the transmission, you’ll be able to check every single internal part and ensure there are no surprises down the road.

Rebuilt transmissions are likely to last for a very long time, but they are expensive to rebuild. It is important to note that rebuilding your car’s transmission gives you certainty that every component is in good working order.

Is a Transmission Rebuild Worth It?

In light of recent economic events, you may wonder whether it’s even worth rebuilding your car’s transmission. Rebuilding a transmission, buying a junkyard replacement, or purchasing a remanufactured transmission are all options for fixing a broken transmission.

In If you can afford it, remanufactured transmissions will probably last another 200,000 miles. Rebuilding your transmission can save you some money if it’s possible. Last but not least, if you’re on a really tight budget, consider replacing your transmission with one from a wrecked vehicle.

There are many factors to consider when choosing the best option for your case. Let’s go over most of them now.

Is it cheaper to Rebuild a Transmission Instead of Replacing it?

Rebuilding a transmission is cheaper than replacing it. New transmissions can cost well over $4000 while rebuilding could cost between $1500 and $4000. In contrast, it may be faster to replace a failed transmission than to rebuild it. The lasting time of a rebuilt transmission varies. About 50,000 miles is the average lifespan of a rebuilt transmission. Alternatively, a new transmission will last up to 300,000 miles if it serviced and checked frequently.

Transmission rebuild vs. Remanufactured Transmission

In some cases, remanufactured transmissions are better than rebuilding your car’s transmission. A remanufactured transmission may be better than a rebuilt transmission in some cases. As a result, a remanufactured transmission returned to its factory settings by the remanufacturer.

Only remanufactured transmissions handled by these specialists. You can replace your failed transmission with a ready-and-waiting remanufactured one. Experts who conduct it thoroughly examine the transmission in a manner similar to a transmission rebuild.

In order to restore the transmission to its original state, they replace all the soft and hard parts and use factory settings. Due to the fact that these transmissions built according to the manufacturer’s specifications, they may even be better than the originals. CVT transmission problems and symptoms differ from those of regular automatic transmissions in part because of the type of transmission.

This is due to manufacturers making adjustments to the same type of transmission for upcoming models. This way, you can find a transmission with no known faults that has updated and brought back to factory condition. Having a mechanic that is familiar with your particular transmission type can save you a lot of time and money.

Why a Remanufactured Transmission Might Be a Good Option For You?

Remanufactured transmissions are an excellent alternative to brand-new ones. These are completely reengineered and assembled in a factory. Typically, they upgraded from their stock form, which means they can eliminate many design flaws that cause premature component failure. As a result, a remanufactured transmission will last much longer than an original one.

Each remanufactured transmission from Street Smart Transmission undergoes a rigorous build process to ensure quality. Nearly 100 technicians specialize in different aspects of the construction process.

During this remanufacturing process, all of the crucial components from the donor transmission tested to ensure that they meet the original equipment specifications. Cases, pumps, gears, shafts, valve bodies, torque converters, and other components examined for hairline cracks, metal tensile strength, warping, etc. Components that do not meet the specifications discarded and replaced.

Once the parts have cleaned, they sent to the appropriate assembly stations for reassembly. It is the responsibility of quality control managers to ensure that the build meets the specified parameters throughout the process. Any necessary modifications or upgrades are also performed or added in order to fix factory design flaws. A dyno machine used to test the valve body and ensure it performs as specified. Prior to installation, all solenoids tested.

A newly remanufactured transmission goes to the dyno room for testing after its final quality control inspection, using software called CARS (Computer Aided Real-World Simulation) to simulate the real world. A number of real-world driving situations cycled through the transmission to ensure it performs as specified by the factory. As well as breaking in the friction components, it also ensures that it is completely ready to use once it installed.

What to Expect After a Transmission Rebuild?

When your transmission is rebuilt, your vehicle will drive smoother and shift more smoothly. Rebuilding your transmission should restore your vehicle’s performance and reliability.

As part of the rebuilding process, the transmission disassembled, inspected, and rebuilt with new or repaired parts. Taking care of existing transmission problems, such as slipping or shifting, will prevent future problems.

It will be necessary to inspect the transmission after the rebuild has completed to ensure that it is operating properly. Diagnostic equipment may used to check for issues during the test drive.

It’s important to keep in mind that a transmission rebuild might solve some problems with a defective transmission, but it might not address all your concerns. Also, the engine or drivetrain may need to inspected and repaired.