Wheel lugs secure your Jeep’s wheels to the chassis. This wheel and axle hub has three to eight lugs evenly spread around the centre hub. A wheel’s bolt pattern describes the arrangement of bolts around its hub. Depending on the vehicle’s bolt pattern, some diameters and widths of wheels might not fit. But what is the 2015 Jeep Cherokee bolt pattern?

It’s not noticeable if you look closely at automotive wheel bolt patterns. Yes, counting lugs on a wheel is easy. However, it is not so obvious that two wheels with a four-bolt pattern might not fit the same vehicles. For vehicles of a particular size, manufacturers usually use the same bolt pattern, but not always. Bolt patterns are also different between manufacturers.

Read the article to learn more about the 2015 Jeep Cherokee bolt pattern and apply it to your vehicle.

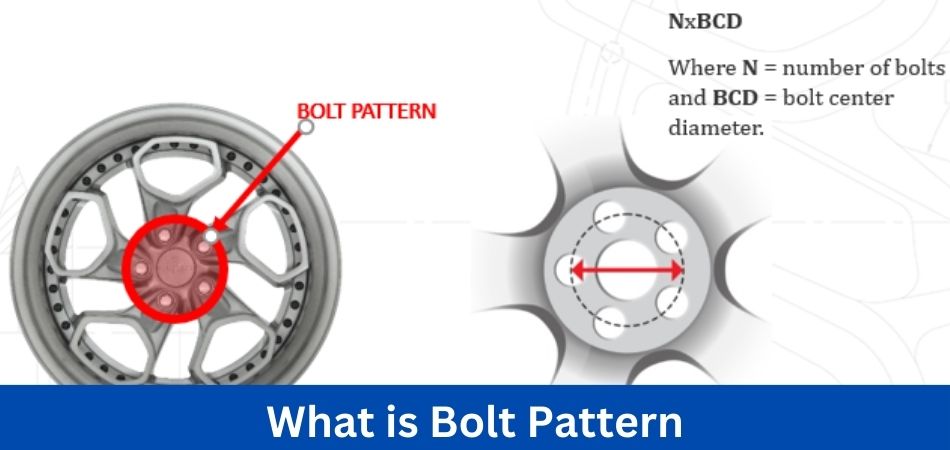

What Is a Bolt Pattern?

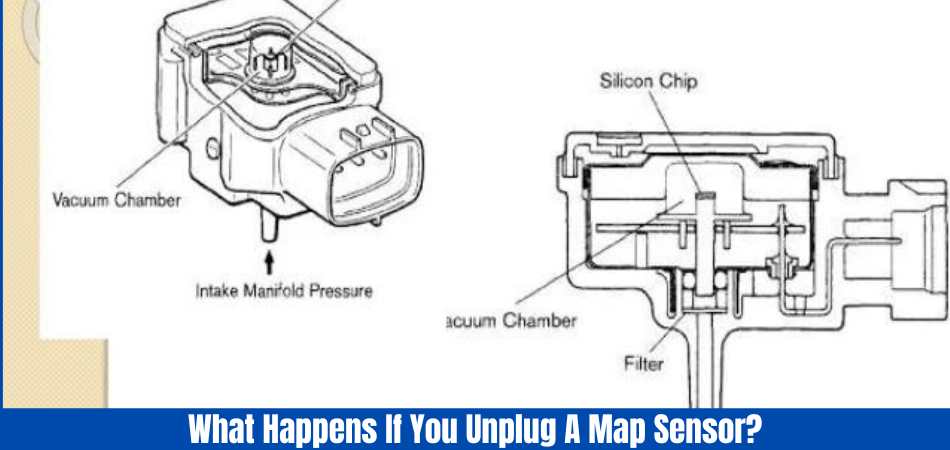

A tire’s bolt pattern indicates the number of bolts or lug nuts used to secure the wheel to your vehicle and its pitch circle diameter. That’s right. There’s something confusing about that.

Let’s take a look at it in more detail. In a bolt pattern, you need to look for two numbers. For instance, 5×110. There are five bolt holes or lug holes on the wheel indicated by the first number.

If that’s the case, what does 110 mean? An imaginary circle is formed by the boltholes at the centre of your wheel. In order to determine the second number, you need to calculate the circle’s diameter around the holes.

So This wheel has five boltholes evenly spaced around a circle with a diameter of 110 mm.

How Bolt Pattern Is Written?

An illustration of the bolt pattern is represented by a code consisting of two numbers. For example, a typical four-lug wheel has a bolt pattern of 4-4.25″. There are four lugs on the wheel, arranged around a circle 4.25 inches in diameter. Eight lugs are arranged in a circle 7.87″ in diameter on a wheel with a bolt pattern of 8-7.87″. Below is a table listing common bolt patterns for wheels with four, five, six, and eight lugs.

| 4-Lug Bolt Pattern Conversions (mm to Inches) | ||||

| 4-98mm→4-3.86” | 4-100mm→4-3.94” | 4-108mm→4-4.25” | 4-110mm→4-4.33” | 4-114.3mm→4-4.5” |

| 5-Lug Bolt Pattern Conversion (mm to Inches) | ||||

| 5-98mm→5-3.86” | 5-100mm→5-3.94” | 5-108mm→5-4.25” | 5-110mmć5-4.33” | 5-112mm→5-4.41” |

| 5-114.3mm→5-4.5” | 5-115mm→5-4.52” | 5-120mm→6-4.72” | 5-120.7mm→5-4.75” | 5-127mm→5-5” |

| 5-130mm→5-5.12” | 5-135mm→5-5.3” | 5-139.7mm→5-5.5” | 5-150mm→5-5.91” | 5-155mm→5-6.1” |

| 5-165.1mm→5-6.5” | 5-205mm→5-8.07” | |||

| 6-Lug Bolt Pattern Conversion (mm to Inches) | ||||

| 6-114.3mm→6-4.5” | 6-115mm→6-4.52” | 6-127mm→6-5” | 6-132mm→6-5.2” | 6-135mm→6-5.3” |

| 6-139.7mm→6-5.5” | ||||

| 8-Lug Bolt Pattern Conversion (mm to Inches) | ||

| 8-165.1mm→8-6.5” | 8-170mm→8-6.69” | 8-200mm→8-7.87” |

How to Measure the Bolt Pattern in 2015 Jeep Cherokee?

Aside from keeping track of your car’s bolt pattern, you must also keep track of its measurements. It is always important to know the bolt pattern’s diameter and the number of holes.

It comes in a number of different hole and size combinations, but they are all listed on a chart. Therefore, they aren’t random. Reading them while shopping is as simple as knowing what’s happening.

There are two types of bolt patterns, each classified by a different number. Suppose, for instance, your car has bolt pattern measurements of 4-4.5″. The first number indicates how many lug bolts your car has, and the second number indicates how big those five lug bolts are.

- 4 Lug Wheels

Since the 1960s, four-lug wheels have been common on compact cars. Ford Falcon and Mustang models of the 1960s used four-lug hubs and wheels on select trim levels, as well as the Ford Falcon.

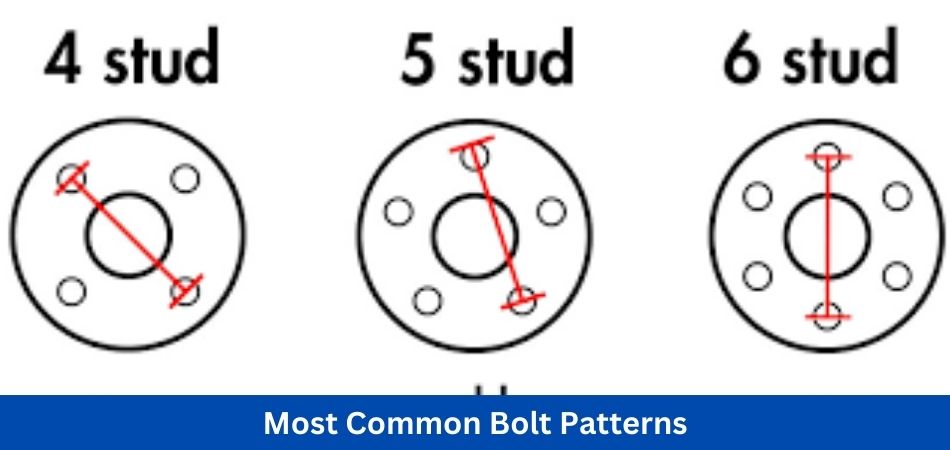

Several different bolt patterns are available for four lug wheels, including four lugs that are 4×4.5 inches and four lugs that are 4×4.25 inches. The bolt pattern of Volkswagen and other foreign cars is 4x130mm. Measuring from the center of one wheel stud to the center of the one across from it will tell you what bolt pattern you have.

Some manufacturers offer classic 4 lug wheels for many models and makes. You can also choose a Smoothie wheel (available in primer and chrome), Ford Styled Steel, and Vintage Wheel Works V48 wheels with 4 lugs. In addition to the 4×4.25 inch bolt pattern, the Smoothie wheel also includes a 4×4.5 inch bolt pattern. Classic Fords can use the other wheels because they have a single, direct fit 4×4.5-inch bolt pattern.

- 5 Lug Wheels

The most common wheel style in the collector car industry is the five-lug. Ford was the first manufacturer to use a five-lug bolt pattern in the late 1920s. Eventually, other manufacturers followed suit, designating their own bolt patterns, designating larger bolt patterns for trucks and smaller bolt patterns for passenger cars.

There are several companies that offer five-lug wheels in authentic styles to fit 5×4, 5×4.5, 5×4.75, 5×5, 5×5.5 and 5x205mm bolt patterns.

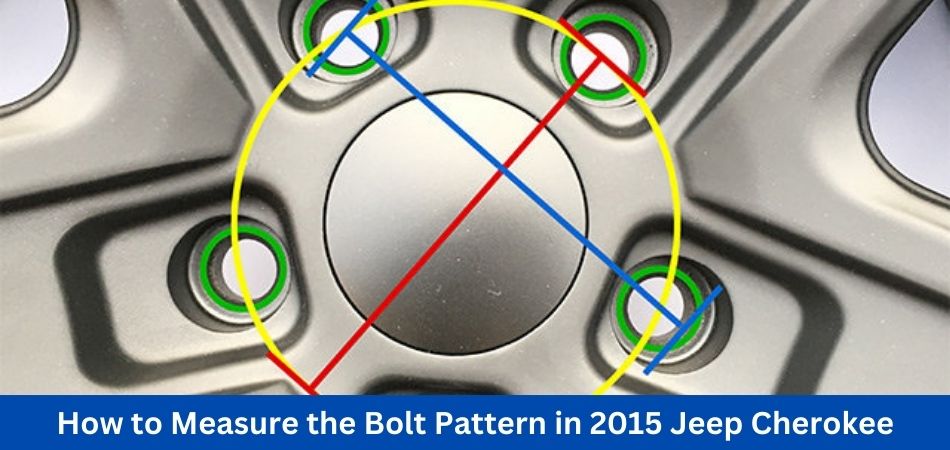

When determining the bolt pattern on a five-lug wheel, measure from the center of the stud to the edge furthest away from it. For an illustration of how it is measured, see the diagram.

- 6 Lug Wheels

This article is straightforward when it comes to the 6 lugs. Thanks to the 6 lug bolt pattern most manufacturers use, light trucks use 6 on 5.5 inches. Even though it’s important to measure, it’s the same pattern on most 1930s through 1980s 6 lug trucks. Using the stud centers as guides, measure the bolt circle from one stud to the next.

For many years, Chevrolet used 6 lug wheels on all of its trucks (and some of its cars). Before 1971, every Chevrolet 3100 and C10 (half ton) truck had six lug wheels. After 1971, Chevy and GMC trucks with four-wheel drive continued to feature six lug wheels

This is how we get the estimated diameter from a bolt pattern of five, but for a more precise reading, you will need something called a Bolt Pattern Gauge. If your vehicle has a five bolt pattern, you’ll be working mainly with estimates.

- 8 Lug Wheels

For increased load capacity, many manufacturers built heavy duty trucks with larger hubs. The result was an 8-lug wheel design that is still popular on 3/4-ton and 1-ton trucks today. There are very few differences between manufacturers when it comes to this pattern. It’s pretty common for 8 lug bolt patterns to have bolt circles of 6.5 inches. You can determine the bolt pattern by measuring from the center of one stud to the center of the one across.

Classic heavy-duty trucks can benefit from 8 lug wheels from Coker Tire. A semi gloss black powder coat or chrome finish is available on the 16-inch wheels.

What are the Most Common Bolt Patterns?

Polaris: The majority of modern and full-sized ATVs and UTVs have 4×156 wheels, except for the Turbo R and Pro R, which have 5×4.5 wheels

Can-Am: Almost all modern and full-size ATVs and UTVs have 4×137 tires

Honda: The bolt pattern on all non-sport ATVs and UTVs is 4×110 except for the Pioneer 1000 and Talon, which have 4×137 bolt patterns.

Kawasaki: The bolt pattern for ATVs with Solid Rear Axles (SRA) is 4×137. The bolt pattern on the KRX 1000 is 4×156. An independent rear suspension ATV uses a bolt pattern of 4×110. Teryx and Mule use a 4×137 bolt pattern with a 12mm stud. The Mule PRO-FXT has a bolt pattern of 4×156.

Yamaha: The 2019+ YXZ uses a 4×156 bolt pattern, which is different from the rest of the non-sport and modern ATVs & UTVs.

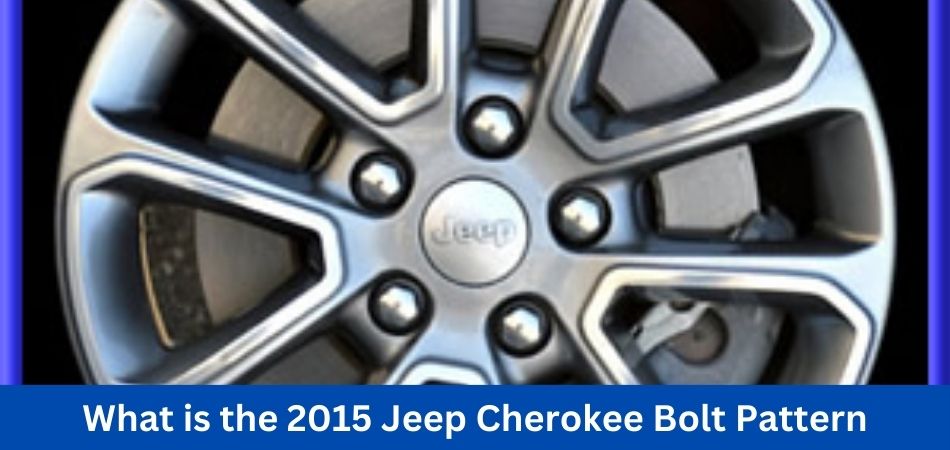

What is the 2015 Jeep Cherokee Bolt Pattern?

A set of wheels on another Wrangler might be more appealing than the wheels on your Jeep. When you were on an adventure last time, you got some ‘off-road’ rock rash and wanted to replace those wheels.

It could be a matter of time. There are times when you need to replace your wheels, and when you do, it can be confusing to determine which bolt pattern will fit your vehicle. Depending on your tires, you may know what wheel size you need, but the bolt pattern is another story.

There are different spacings between the lugs on Jeeps, so although most have five lugs, different models have different spacings. As an example, all JK Wranglers (2007-18) have a 5×5 bolt pattern – five lugs with five-inch spacing. A 5×4.5 pattern is used on earlier TJ and YJ models of the Wrangler (1997-06) and the YJ (1987-95). Below is a Jeep-specific chart that breaks down the year/model and bolt pattern of different Jeeps so you can determine which one applies to your vehicle.

2022-2021

- Jeep Grand Cherokee Bolt/Lug Pattern – PCD 5x127mm

- Center Bore (Hub Bore) 71.5 mm

- Thread Size (Lug Nut Size) – M14 x 1.5

- Tire Sizes – 245/70 R17, 265/60 R18, 265/55 R19, 265/50 R20, 275/50 R20, 295/45 R20, 295/40 R21, 305/35 R22

2020-2016

- Jeep Grand Cherokee Bolt/Lug Pattern – PCD 5x127mm

- Stock Wheel Offset – 44 to 53 mm

- Center Bore (hub bore) – 71.5 mm

- Thread Size (Lug Nut Size) – M14 x 2.00

- Stock Rim Sizes Range – 17×7.5 – 22×12.0

- Custom Rim Sizes Range – R20 – R20

- Tire Sizes – 245/70 R17, 265/60 R18, 265/55 R19, 265/50 R20, 275/50 R20, 295/45 R20, 295/40 R21, 305/35 R22

2015

- Jeep Grand Cherokee Bolt/Lug Pattern – PCD 5x127mm

- Stock Wheel Offset – 25 to 45 mm

- Center Bore (Hub Bore) – 71.5 mm

- Thread Size (Lug Nut Size) – M14 x 2.00

- Stock Rim Sizes Range – 18×7.0 – 22×10.0

- Custom Rim Sizes Range – 20×10.0 – 22×10.5

- Tire Sizes – 245/70 R17, 265/60 R18, 265/55 R19, 265/50 R20, 275/50 R20, 295/45 R20, 295/40 R21, 305/35 R22

2014-2011

- Jeep Grand Cherokee Bolt/Lug Pattern – PCD 5x127mm

- Stock Wheel Offset – 25 to 45 mm

- Custom Offset Range – 10 to 56 mm

- Center Bore (Hub Bore) – 71.5 mm

- Thread Size (Lug Nut Size) – M14 x 2.00

- Stock Rim Sizes Range – 17×7.0 – 22×10.0

- Custom Rim Sizes Range – 18×10.0 – 24×9.5

- Tire Sizes – 245/70 R17, 265/60 R18, 265/55 R19, 265/50 R20, 275/50 R20, 295/45 R20, 275/45 R21, 295/40 R21, 265/40 R22, 285/40 R22, 305/35 R22

How to Properly Torque Bolt/Lug Nuts in 2015 Jeep Cherokee?

Securing those lug nuts once the wheels are on isn’t just lip service. When driving your Jeep, it is crucial to ensure proper safety. When the wheels are on your Jeep, use a lug wrench like the Gorilla Power Lug Wrench to tighten the first lug to the correct torque (your owners manual will tell you the exact torque for your vehicle).

Next, tighten the lug nut adjacent to the one you just tightened. Continue moving across the wheel. Work back and forth across the wheel until all lug nuts have been properly torqued, following the diagram below.

Check our lug nut torque chart to determine the proper torque setting if you do not have an owner’s manual. Be careful not to torque those lug nuts over. If you over-torque the lug nuts on your Jeep, they may shear off, and you may lose control. Make sure you know the torque specs for your vehicle.

How To Change The 2015 Jeep Cherokee Bolt Pattern?

Imagine that you find a set of wheels you really want to put on your Jeep Cherokee, but it doesn’t fit your bolt pattern. However, your search doesn’t have to end there – a number of manufacturers create wheel adapters, especially for such applications.

As the name implies, wheel adapters attach to your vehicle’s axle and simulate a different bolt pattern, thus expanding your wheel options. If you want to adjust your 5×114.3mm car to fit 5x100mm wheels, a good adapter can help.

Conclusion: 2015 Jeep Cherokee Bolt Pattern

When upgrading or customizing the wheels on a 2015 Jeep Cherokee, it is vital to understand the bolt pattern. In adhering to the Jeep Cherokee’s bolt pattern, enthusiasts and owners can explore numerous wheel options, enhance the vehicle’s aesthetics, and increase its performance. The bolt pattern guarantees seamless and enjoyable driving, whether Jeep Cherokee owners are seeking off-road adventures or simply a customized touch.

FAQs

Can I use wheels with a different bolt pattern on my 2015 Jeep Cherokee?

Using wheels with a different bolt pattern may lead to improper fitment and compromise safety. Keep the bolt pattern 5×110 as specified by the manufacturer for optimal performance.

What size wheels can I install on my 2015 Jeep Cherokee with the 5×110 bolt pattern?

Jeep Cherokee wheels will fit 5×110 bolt patterns within the recommended size range. You should always consult your vehicle’s manual or a professional for guidance on the right size wheels.

How safe are wheel spacers for changing bolt patterns?

It is not recommended to use wheel spacers to achieve a different bolt pattern, as this can affect the handling and safety of the vehicle. For 2015 Jeep Cherokee wheels, stick to 5×110 bolt patterns.

Are aftermarket wheels compatible with my 2015 Jeep Cherokee?

It is possible to use aftermarket wheels as long as they have the correct 5×110 bolt pattern. Make sure the aftermarket wheels meet Jeep Cherokee’s specifications and have the necessary load capacity.

What is the best way to measure the bolt pattern on my existing wheels?

Count the lug bolts and measure the distance between two opposite bolt centres to determine the bolt pattern. In the 2015 Jeep Cherokees, the bolt pattern is 5×110.

What is the maximum size of the wheels that can be installed on my 2015 Jeep Cherokee?

Keep wheels within the recommended size range to maintain proper performance and avoid issues with speedometer accuracy, handling, and safety.

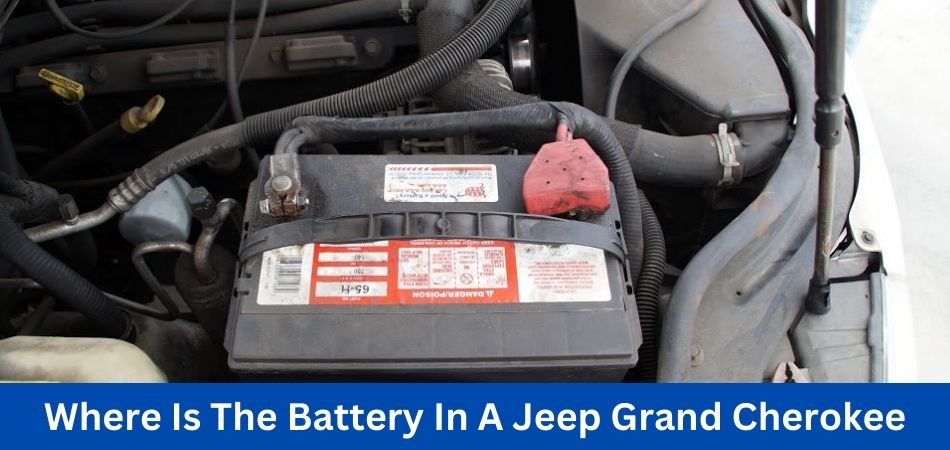

Some Jeep owners might be surprised that their car battery is not under the hood, as it is on most vehicles. A jump-start or battery replacement becomes difficult if you cannot find the battery. So,” where is the battery in a Jeep Grand Cherokee“?

Before even driving a vehicle, knowing the battery’s location is essential. The battery might be hard to track, especially if you have a Jeep Grand Cherokee. You may then wonder where is the battery in a Jeep Grand Cherokee.

Jeep Grand Cherokees are currently available in five generations. Most models with batteries under the hood have theirs in an unexpected place, while others have them under the hood.

To find the Jeep Grand Cherokee Battery conveniently, read through this article until the very end.

Jeep Grand Cherokee: Overview

The Jeep Grand Cherokee is a popular SUV with its rugged design, off-road capabilities, and luxurious features. Jeep introduced the model in 1993, and has remained a staple of its lineup ever since. With its perfect blend of style, versatility, and performance, the Grand Cherokee attracts adventure-seekers and families.

Jeep Grand Cherokee’s powerful engines are one of its standout features. You can choose from several engine options, including V6s and V8s, which provide ample power and fuel efficiency. You can rely on the Grand Cherokee to deliver a smooth, controlled ride, no matter your terrain.

There is no denying that the Jeep Grand Cherokee continues to impress when it comes to interior comfort and technology. A spacious cabin features high-quality materials, supportive seats, and an advanced infotainment system. A touchscreen display, smartphone integration, navigation system, and a premium sound system make driving an enjoyable and connected experience.

Compared to other SUVs, the Grand Cherokee is known for its outstanding off-road capabilities. The Grand Cherokee is no exception to Jeep’s reputation for producing off-road capable vehicles. Various terrain modes, advanced traction control, and advanced 4×4 systems enable the Grand Cherokee to confidently navigate rough terrain and tough conditions.

A variety of advanced driver assistance systems are available in the Grand Cherokee in terms of safety. The Grand Cherokee prioritizes your safety on the road with blind-spot monitoring, forward collision warning, and lane departure warning. Moreover, the Grand Cherokee’s excellent crash test ratings suggest its sturdy construction and robust safety features.

The Jeep Grand Cherokee is an excellent choice for style, performance, and versatility. Grand Cherokee SUVs are reliable and capable of handling every aspect of your life, whether driving to work, taking your family on vacation, or going off-road. In the SUV market, the Grand Cherokee continues to offer a wide range of features, a comfortable interior, and a rugged design.

Why is the Battery Location Of Jeep Grand Cherokee Important to Know?

If you’re a Jeep enthusiast who enjoys exploring and going on adventures, the Jeep Grand Cherokee is for you. Therefore, we all want to keep the power supply uninterrupted and in perfect condition.

It is crucial to have a good battery. As well as protecting your Jeep’s electronics, it also acts as a surge protector. The battery powers your Jeep’s lights, GPS, and stereo when the engine turns off.

In order to locate your Jeep Grand Cherokee’s battery, you must know its location. You should also know the battery location for the following reasons:

1. Easy Replacement

Your Jeep Grand Cherokee’s battery might need a replacement or changes after a while, especially if it’s a bit older. It’s a pretty simple task, but you may need to take it to a repair center since you don’t know where the battery is.

It is possible to replace the battery without additional fees if you know its location. Additionally, it simplifies your job.

2. Connectivity Error Help

The lights or stereo can have a problem, causing you to have trouble starting. In addition, it relates to the connection of the battery. Reconnecting can solve the problem completely.

You can easily access the battery if you know where it is and see if there are any connection errors!

3. Jump Start

In order to jumpstart your Jeep Grand Cherokee, you should connect the jumper cables to the battery terminal. Your engine needs a jump if it suffers a sudden power failure or you need to open the trunk without a key.

The battery must be accessed quickly in such emergencies, and you must jumpstart the vehicle as soon as possible.

4. Inspection of batteries

The battery in your Jeep Grand Cherokee will need inspection regularly if it is an older model.

5. Get Battery Fuel

Occasionally, the battery can’t supply the power you need due to a fuel crisis. The battery needs refilling with fuel, therefore. The battery location becomes quite helpful in such cases.

Without it, you can’t fill up your Jeep’s battery with fuel, and minor problems might require a trip to the shop.

Where Is The Battery In A Jeep Grand Cherokee?

The Jeep Grand Cherokee is one of the most popular and best-selling SUVs in the United States. The Jeep model combines adventure, sports, and luxury.

Because of this, all generations of the Jeep Grand Cherokee have become equally popular over the years. But, where is the battery in a Jeep Grand Cherokee?

Since 1993, the Jeep Grand Cherokee has had five generations. It is not true that all model years have a similar location for the vehicle’s battery.

Hence, you must know its exact location before interacting with it physically.

- 1st Generation Jeep Grand Cherokee Battery Location

1993 marked the beginning of the Jeep Grand Cherokee’s journey. The first generation continued until 1998. Unlike other SUVs, the under-hood engine layout remained the same.

Therefore, the first-generation Jeep Grand Cherokee battery was under the hood. Tracking the battery requires looking at the compartment left to the engine, just behind the passenger.

You simply need to pull the latch under the driver’s seat to replace the battery. Connect the negative and positive terminals after securing the hood.

Use a ten mm socket wrench and regular pliers to remove the brackets and pull off the battery.

- 2nd Generation Jeep Grand Cherokee Battery Location

After the first generation of Jeep Grand Cherokee, the second generation started in 1999. The program lasted five years and ended in 2004. Modifications and developments were few.

Accordingly, the battery is still in the exact location as in the previous generation. However, the second-generation Jeep Grand Cherokee battery location undergoes a slight alignment and shift.

During the car’s second generation, the battery locates on the extreme left side of the engine bay. Under the driver’s side dash, it is readily visible once you open the hood.

Additionally, those vehicles lack battery covers, so removing and replacing batteries requires only pliers and a wrench of a specific size.

- 3rd Generation Jeep Grand Cherokee Battery Location

Jeep Grand Cherokees were available in two segments in the third generation. Between 2005 and 2010, it received its WK and WK Facelift. This generation has seen a lot of change, especially in the engine bay.

The first thing you’ll find when you pop the hood is the battery bracket or case. Under the passenger seat, the battery location has been completely changed from under the hood.

As a result, if you plan to remove, service, or replace the battery on a third-generation Jeep Grand Cherokee, you should check directly under the front passenger’s seat.

Despite the newer arrangements, interacting with the battery was difficult. Removing the firewall allowed advanced features near the engine components without interfering with the engine bay.

- 4th Generation Jeep Grand Cherokee Battery Location

The Jeep Grand Cherokee’s fourth generation also had three sub-segments like its third generation. The fourth generation includes the WK2, WK2 Facelift, and WK2 Facelift2 models.

Since 2005, the generation has been in production. The battery location, however, did not change significantly. As in the previous generation, it was under the front passenger seat of the Jeep Grand Cherokee.

To interact with the battery, you must disassemble the entire seat. Use the seat shift switch on the right panel to elevate the seat.

Under the passenger seat, if you approach the cabin from the back, there is a small compartment. To remove it, use a flathead screwdriver. As a result, your vehicle’s battery will degrade

- 5th Generation Jeep Grand Cherokee Battery Location

Jeep Grand Cherokee’s fifth generation is the latest model in the series. Since 2022, it has been known as WL. After the fourth generation, no changes are made to the battery location.

Under the front passenger seat is your fifth-generation Jeep Grand Cherokee. Elevate it from the ground and shift it to the front. You can now remove the battery compartment cover by using a flathead screwdriver.

The whole battery is exposed for replacement as soon as the cover is removed.

| Make | Year | Model | Engine Size | Battery Group / CCA | Battery Location |

| Jeep | 2020 | Cherokee | L4-2.0L | H7 / 700 CCA | Aft of the left headlight assembly, in front of the engine compartment. |

| 2019 | Cherokee | L4-2.0L | H7 / 700 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2019 | Cherokee | V6-3.2L | H7 / 700 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2018 | Cherokee | L4-2.4L | H6 / 600 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2017 | Cherokee | L4-2.4L | H6 / 600 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2016 | Cherokee | L4-2.4L | H6 / 600 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2015 | Cherokee | L4-2.4L | H6 / 600 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2014 | Cherokee | L4-2.4L | H6 / 600 CCA | Aft of the left headlight assembly, in front of the engine compartment. | |

| 2013 | Grand Cherokee | V6-3.6L | H7 AGM / 700 CCA | Under the front seat of the passenger. | |

| 2012 | Grand Cherokee | V6-3.6L | H7 AGM / 700 CCA | Under the front seat of the passenger. | |

| 2011 | Grand Cherokee | V6-3.6L | H7 AGM / 700 CCA | Under the front seat of the passenger. | |

| 2010 | Grand Cherokee | V8-4.7L | H8 / 850 CCA | Aft of the left headlight assembly, in front of the engine compartment. |

Why Is The Jeep Grand Cherokee Battery Located Under The Passenger Seat?

Jeep owners are scratching their heads and blaming Jeep manufacturers for placing the battery in an inaccessible place since it’s typically easily serviced and accessed.

Several factors led the manufacturer to place the battery under the passenger seat rather than under the hood.

It’s not an innovation, especially for Jeep. Jeeps designed for WWII had batteries located under the seats beneath the floorboards. The design pays tribute to the original design and serves a practical purpose.

This may be because lead-acid batteries cannot operate above 120 degrees Fahrenheit. The radiator gets extremely hot, so keeping the battery close isn’t a good idea.

Moreover, the manufacturers may have preferred to use valuable engine compartment space for the engine and other components.

What Is The Jeep Grand Cherokee’s Battery Size?

Most Grand Cherokees use batteries with a group size of 34, or H7 or H8 batteries. In the latest model, the battery is an H7, which we call ‘DIN’ compatible. Reviewing the chart, you can find more information about Jeep Grand Cherokee’s amps and battery size.

| Battery Type | Engine | Cold Crank AMPS |

| H7-AGM | V6/3.6L | 850 |

| H8-AGM | V6/3.0L | 900 |

| H7-AGM | V8/6.2L | 850 |

| H7-AGM | V8/6.4L | 850 |

| H7-AGM | V8/5.7L | 850 |

When Should You Replace Jeep Grand Cherokee Battery?

It is essential to check the voltage drops regularly to ensure the battery works properly. Even though batteries typically last for five years, confusion arises when they begin to malfunction early. Your first question is, “When should you replace the Grand Cherokee battery?”

When starting the car, you may hear clicking sounds, indicating a battery problem. If the Grand Cherokee battery becomes corroded, it must be replaced.

If you replace a battery that has been regularly discharged, you don’t have to jump-start the car or change the lights.

How To Remove A Jeep Grand Cherokee Battery?

Removing or replacing a Jeep Grand Cherokee battery is the most challenging part. A tight fit can make moving the battery a little frustrating because you have to maneuver the passenger seat. You may find it helpful, however, to move your seat as far forward as possible.

For models between 2011 and 2021, follow these steps to remove the car battery. The same applies to models with two batteries or without.

Step 1: Move The Seat

Moving the passenger seat forward is the first step. It can be difficult to move it when you’ve never done it before. The user guide for your vehicle can help you determine how to do it for the first time.

In order to move the seat forward, you typically have to raise or move knobs or levers. To move the seat, follow the instructions in the guide to locate the lever. Make sure you move it as far forward as possible.

Step 2: Lift The Carpet

You usually need to lift a panel on the vehicle to access the battery. Nevertheless, you need to lift both the panel and carpet simultaneously. It may be easier to lift the carpet first before the panel.

Step 3: Remove One Battery Cable

Lifting the panel from the floor will allow you to remove one cable at a time. You will need a wrench to loosen the fastener on the negative battery cable.

You likely already have a handy wrench for this purpose, so pull it out and use it right now. You might have to borrow one to loosen the fastener if you don’t have one. Ensure that the battery head is not damaged during this process. After loosening the cable, remove it from the negative terminal.

Step 4: Pull Out The Vent Tube

The next step is to locate the vent tube on the battery. You should find instructions in the user guide on how to find it and what it looks like.

You can find it on the battery’s side. Pull it out. Afterwards, locate the hold-down plate with the two fasteners on the battery. A wrench will be needed to loosen and remove these fasteners.

Step 5: Remove The Second Cable

The next step is to remove the positive battery cable from the positive terminal. Pull the cable off by loosening the fastener with the wrench. To avoid damaging the other cable, do this carefully.

Step 6: Lift The Battery Out Of The Car

Once all the cables are loose and off the battery, you can lift the battery out of the car. Nevertheless, because of the space issue, it may be necessary to wiggle the battery before removing it.

What are the Tips For Maintaining The Battery In Jeep Grand Cherokee?

When you are in the middle of an adventure or journey, checking the battery multiple times would be a hassle. In order to avoid such situations and issues, it is best to keep the battery in good condition. Here’s what you need to do:

1. Charge the battery and check its condition

You should check the battery charge level and current condition if you’ve used the battery for a long time.

Make sure your battery is fully charged whenever you go for a drive. Make sure the battery is regularly in good health. Your Jeep should be taken to a repair shop if something seems suspicious.

2. Clean the terminals and battery of the battery

The problem with filthy batteries is that they get unhealthy too quickly. Therefore, you won’t be able to jumpstart your Jeep Grand Cherokee without a functioning battery.

If the terminals are corroded, the connection can be hampered, and a power outage could occur. Therefore, it is best to keep the terminals and battery clean.

3. Keep your batteries in a proper storage place

When replacing a battery, we sometimes forget to place it properly. Jeep Grand Cherokees are built for off-road adventures.

In this case, the battery will be subjected to several shocks and impacts without proper placement, resulting in damage. As a result, you must store the battery correctly.

Conclusion: Where Is The Battery In A Jeep Grand Cherokee

Now you might get the answer: where is the battery in a Jeep Grand Cherokee? It is your responsibility to know everything there is to know about your Jeep as a Jeep owner. You should know the location of the battery as one of the most essential pieces of information.

No matter how often your Jeep is serviced, you should know where the battery is. Also, it can be used for minor repairs, such as tightening loose connections, jump-starting, replacing batteries, etc.

We hope that we have covered all your questions regarding the location of the Jeep Grand Cherokee battery. Have a safe drive on your adventures!

FAQs

Do Jeep Grand Cherokees have two batteries?

The engine cranking and ESS systems on some Jeep Grand Cherokees are powered by dual batteries. There is only one powerful battery in the Jeep Grand Cherokee, however.

What is the life expectancy of a Jeep Grand Cherokee car battery?

On A Jeep Grand Cherokee car battery typically lasts 3-5 years. With regular maintenance and recharging, the battery can last for 6-7 years. A vehicle’s driving style and maintenance affect the battery’s lifespan.

How Much Voltage Does A Jeep Grand Cherokee Battery Have?

For Jeep Grand Cherokees, a healthy battery is between 13.5V and 14.3V. The SOC gradually decreases over time. It is recommended to recondition or replace a battery if its SOC is below 70% or 12.6V.

What is the location of the Jeep Cherokee’s start/stop battery?

The auxiliary battery is the name given to the auto start/stop battery in Jeep Grand Cherokee. Additionally, it is located next to the main battery under the passenger seat. Jeep Grand Cherokees are not all equipped with auto start/stop batteries.

Cars generate all kinds of weird noises due to so many moving parts, fluids moving about, and different electrical components, many of which are normal and pose no cause for concern. However, sometimes you might notice that your Car makes humming noise when parked.

If you hear a humming noise when your car is parked, it could be the radiator fan, electric water pump, EVAP leak test, DPF regeneration, or a malfunctioning alternator. It’s the battery cooling system buzzing if you have an electric vehicle.

Read this comprehensive article explaining causes and solutions for why “your Car makes humming noise when parked.“

Is It Normal for Cars to Hum?

Cars create a variety of noises, and as long as you don’t hear any loud buzzing, metal grinding, whirring, clunking, or whining, there’s no need to call 911. Humming, for example, is one of the more innocuous noises you might hear in a car and is usually caused by the normal working of various components.

Humming Noise from Gas Cars When Parked

After parking in the garage for a few hours, you may notice a humming noise coming from the back of the automobile. That is the sound of the gasoline evaporation leakage test, and you should not be alarmed. The vehicle has an evaporative emission control system (EVAP), which seals the fuel system and prevents fuel vapors from escaping into the surrounding air.

When fuel vapors come into touch with air and sunshine, they produce smog, which is extremely damaging. The fuel pump is used to pressurize the vehicle system and test for leaks during the evaporation leakage test. Most cars are set to run this test after five hours of parking because every metallic will have contracted at that point, making it more straightforward to identify leaks. The check engine light on the dashboard will illuminate if the vehicle senses a leak.

Humming Noise from Electric Cars When Parked

Most individuals, including EV owners, are probably unaware that electric vehicles have a cooling system. Electric vehicles’ cooling system is needed to warm up the battery on cold days and cool it down because it is prone to overheating when in operation. The same is true for electric motors.

The cooling system employs ordinary coolant and a water pump to transfer the coolant. And the humming noise is caused by the water pump in conjunction with the coolant flow. The noise is significantly more noticeable in electric automobiles because there are no engine sounds, and what may confuse people is that the coolant does not circulate as frequently.

However, this is not cause for fear because if the battery overheated, you would receive a message, and if it were frozen, the same thing would occur. This precise explanation can also be found in your owner’s handbook; if not, it can be found on the dealer’s website.

Why Does a Car Make Humming Noise When Parked?

A car generates a humming noise when parked for various reasons, including electricity, fuel, AC system, brakes, inner CV joint, a faulty alternator, water pump bearing, transmission oil level, and tire balance.

Knowing the exact source of the buzzing sound is critical since it could indicate a serious problem that requires professional repair.

1. The electrical system

A weak or failing battery or a defective electrical component could cause a buzzing noise in your car. A buzzing sound might be produced when the alternator works harder than usual to charge a weak battery.

On the other hand, a short circuit or poor wiring in the electrical system can cause numerous components to create a buzzing noise.

2. The fuel system

When stopped, a car that makes a humming noise could indicate a significant problem with the fuel system. A faulty fuel pump could cause the noise. A buzzing sound might also be caused by debris in the fuel lines.

Other signs, such as difficulties starting your automobile or poor performance, indicate that the fuel pump needs to be changed.

3. System of air conditioning

Your car’s air conditioning system can potentially cause a buzzing noise in a parked automobile. When you switch on the air conditioner, the compressor or other system components may whine.

If your vehicle exhibits other symptoms, such as warm air from the vents or a weird stench, your AC system will likely need repair.

4. Brakes

If your parked automobile makes a grinding or droning noise, it could result from worn brake pads. A humming sound can be produced when the pads’ metal brushes against the rotors.

Other signs of worn brake pads include a pulsing sensation in the brake pedal and trouble stopping. The problem should be resolved by replacing the brake pads.

5. CV joint on the inside

If you hear a loud humming noise coming from your car, it could be due to a deteriorating inner CV joint. The inner CV joint is a component of the driveshaft that aids in the transfer of power from the transmission to the wheels.

Vibrations or unusual noises while driving are signs of a damaged CV joint. As a result, replacing the CV joint is frequently required to resolve the problem.

6. Alternator failure

A faulty alternator might also cause your vehicle to hum. The alternator is in charge of charging the battery and producing electricity for the electrical system.

If broken, it might cause shaking even when the automobile is parked. Dimming headlights or a dead battery are two other signs. The alternator must be replaced to resolve the problem.

7. Bearing for a water pump

If your car makes a constant humming noise when parked, it could be due to a faulty water pump bearing. To prevent overheating, the water pump circulates coolant through the engine.

Overheating or coolant leaks are signs of a failed water pump bearing. To resolve the problem, the water pump must be replaced.

8. Level of transmission oil

Transmission is poor. A low oil level or transmission problems might also cause the automobile to make noise when parked.

Symptoms of transmission problems include slipping gears, difficulties shifting, and a burning odor. Transmission repair or replacement may be required to resolve the issue.

9. Wheel alignment

A humming noise from your parked car could be caused by faulty wheel balancing.

This warning sign is usually more visible at highway speeds, although you may still hear it when the car is parked. Having your wheels balanced or rotated may assist to remedy the problem.

How to Identify the Source of the Humming Noise?

Understanding what’s creating a noise can help you determine where it’s coming from. Here are some measures you can take to figure out where the humming sounds are coming from:

- Pay close attention: Start your car and let it idle for a few minutes. Determine where the noise is originating from. Is it louder behind the hood, or can you hear it better inside?

- Check Your Fluids: A buzzing noise might be caused by low fluid levels in the power steering or gearbox. Check to see if these fluid levels are low.

- Examine the Alternator: If the noise becomes louder when you turn on electrical components (such as your headlights or air conditioning), the alternator may be the source of the problem. A professional inspection may be required to validate this.

If the buzzing noise starts when you switch on your air conditioning, there could be a problem with the AC compressor. Again, you may need to consult with a specialist to confirm this.

Remember that determining the source of a noise can be difficult. Having a technician look at it is always a smart idea if unsure.

How To Fix The Car Making Humming Noise When Parked Problem?

If your car makes an obnoxious noise while stopped, it could indicate a more significant problem. Here are some potential solutions to the car buzzing when turned off problem:

1. System of electricity

A defective alternator or a weak battery might cause a continual humming noise. You may need to replace or repair the faulty component to resolve this.

If there is a short circuit or defective wiring, a mechanic must diagnose and repair the problem.

2. Fuel system

A humming noise caused by a clogged fuel filter can be resolved by replacing it or by a professional.

Check the fuel system and consult a mechanic if the fuel pump is the problem.

3. Air conditioning system

A standard automobile noise from the air conditioning system can signal a compressor problem or a loose belt. Bring your vehicle to a repair shop for a diagnosis.

4. Brakes

Humming or clicking noises might be caused by worn brake pads. To correct this, you must replace the brake pads. If the rotors are damaged, they may also need to be replaced.

5. Wheel Bearings

A professional should replace worn wheel bearings if they are causing common automotive noises.

Driving with worn-out wheel bearings can cause major damage to your vehicle, so it’s critical to solve this problem as soon as possible.

6. Regular upkeep

Regular maintenance eliminates humming noises and keeps your automobile running smoothly.

Routine maintenance, including oil changes and tune-ups, can help prevent problems before they become major concerns.

7. Other elements

If none of the aforementioned alternatives work, there could be other underlying concerns. A specialist can identify the issue and advise you on the best action.

Taking your automobile to a competent mechanic and treating any faults immediately will prevent future damage and guarantee your vehicle works smoothly.

What are the Other Strange Noises from Your Car, and What Do They Mean?

1. Droning sound

The car can make droning noises when the tires are in poor condition. It gets more noticeable when doing corners or speeding. Tires are a vital component of every vehicle. A new pair of tires will always provide a smooth ride on the road.

2. Squealing Noise

The front end of the car occasionally makes a squealing sound. As soon as you start the vehicle, the sound becomes noticeable. The serpentine belt is the primary source of the squealing sound. The belt passes via several pulleys and wheels. It can even run on the compressor, alternator, or pulleys of the car.

After repeated use, the belt might become damaged, resulting in a screeching sound. So, if you hear such a noise, immediately inspect the belt. If you do not do this, the belt may fall off the compressor or alternator, causing the air conditioning to fail. The car may even halt in the middle of the road at times.

After hearing this noise, please inspect the tires. If the tires are underinflated, you must inflate them if you suspect feather tires (treads that have worn out and are no longer harmful).

3. Rattling sound

While driving over potholes or bumps, you may hear rattling sounds from the car. Several things are going on in the vehicle’s front end. Aside from the engine, the car’s front end has a suspension system with several significant components.

Worn bushings can cause a rattling noise. A bushing aims to dampen vibration, reduce noise and friction, and absorb road bumps. Rubber is used to make these bushings. However, they can be shattered with time, resulting in a rattling sound from the car.

However, other reasons may be, such as worn struts, ball bearings, or sway bar links. It’s difficult to isolate the components causing the rattling sounds. When the automobile is in the parking position, you can do a bounce test at home.

Firmly press down on the vehicle’s front end. It may not tell you which bushing is faulty, but it will tell you whether or not the suspension system is to blame for the rattling sound. Take your vehicle to a local repair if you hear the noise throughout each bounce test.

4. Whining or Squeaking Sound

Low-power steering fluid might generate squeaking, groaning, or whining when rotating the steering wheel. To function correctly, the power steering system in older vehicles requires fluid. When the fluid level drops, turning the steering wheel becomes difficult. You may also hear squeaky or whining sounds. You can resolve the issue by topping off the power steering fluid reservoir.

Other factors could exist as well. For example, if the power steering pump fails, air might enter the lines and cause squeaking or whining.

5. Growling or screeching

If you hear a screeching or growling sound when you step on the brakes, there could be a problem with the car’s brakes, which is unsafe. Brakes are an essential component of any vehicle. The brake pads have worn out if the automobile makes a lot of noise when you step on the brakes.

However, if it makes a tiny screaming or growling noise when you step on the brakes, the brake pad is deteriorating, and the caliper is grinding on the rotor. In both circumstances, the brake pad must be replaced.

6. Loud Bang

Hearing a loud blast from the back of the automobile, akin to a firecracker or gunshot, is rather alarming. In most situations, the cause is an insufficient mixing of air and fuel in the combustion chamber. More fuel and less air in the chamber can result in a loud bang sound.

There could be other factors as well. For example, there could be a problem with the sparkplug. Hearing such a loud bang implies that the engine is working well. The car’s exhaust system may be irreparably ruined if you don’t address the problem immediately. As a result, we urge that you take the car to a qualified auto repair shop immediately.

7. Rumbling

You may hear a rumbling sound and feel vibrations when the vehicle is idling. It suggests several probable explanations. An improper air-fuel combination in the combustion chamber could cause this problem. Fuel injectors might become clogged over time and no longer give adequate fuel to the combustion chamber.

Furthermore, if the air filter becomes clogged, there will be no oxygen in the chamber. You may fix it by replacing the air filter.

Occasionally, the oxygen sensors fail over time, which could explain the rumbling sound. There could be a problem with the spark plug. A rumbling sound will be heard if the sparkplug does not consistently burn the air-fuel mixture.

8. Knocking

A knocking sound may be heard from the car’s engine hood. When the fuel inside the combustion chamber burns simultaneously, the engine runs properly. However, a banging sound is produced if the fuel does not burn simultaneously. Using low-octane fuel, you may occasionally hear a knocking sound from under the hood.

Sounds like the washing machine is on high spin.

If you are on the road and hear a sound from a vehicle, such as a washing machine running at high speed, the problem is severe. The lug nut may be loose, indicating the car’s wheels are not correctly attached. So, take the vehicle to the nearest repair as quickly as possible.

9. Roaring sound

While speeding, you may hear a roaring sound. There could be several explanations for this. For example, if there is a problem with the catalytic converter, you will hear such a sound.

All the exhaust gasses are normally sent through the muffler, reducing the roaring sound. However, if there is a crack in the exhaust system, the gases will escape before reaching the muffler, resulting in a roaring sound.

When to Consult a Professional Mechanic?

While some automotive problems can be resolved at home, there are instances when you should take your vehicle to a professional technician. Here are some examples of when you should seek expert assistance:

- Unsure of the Noise Source: If you’ve tried to locate the source of the humming noise but are still unsure, a mechanic can assist you. They have the skills and experience to swiftly and reliably identify noise sources.

- Sophisticated repairs: such as changing an alternator or a transmission, necessitate using specialist tools. If this type of repair is required, leaving it to a professional is preferable.

- Persistent Noise: A mechanic can assist if you’ve attempted to resolve the issue, but the humming noise persists. Sometimes, the problem is more intricate than it appears.

Final Thought

When your automobile is parked, a humming noise can indicate various problems, ranging from power steering troubles to a broken alternator. While determining the noise source can be difficult, the problem can be identified and resolved with the appropriate methodology.

Remember, if you’re unsure about a noise your automobile is making, you should always visit an expert.

Read more of our articles here.

Read Also: Common Car Noises and What They Mean.

FAQs

Can Tires Cause Your Car to Hun?

Technically, tires produce a buzzing noise that increases in volume with speed, but it sounds similar to wind noise and does not draw your attention. Other components, such as the radiator fan, AC fan, and electric water pump, can hum under specific conditions.

How Can I Make My Electric Water Pump Quieter?

There is no method to reduce electric water pump noise as long as the engine and cooling system are operational. However, suppose the water pump becomes louder than usual. In that case, you should have your cooling system serviced because the automobile could suffer from a faulty water pump, insufficient coolant, or air trapped in the system.

What Is the Noise of a Faulty Radiator Fan?

A functioning radiator fan generates a humming or high-speed wind noise. On the other hand, a malfunctioning radiator fan can generate a grinding noise, indicating that its bearing is worn out, or a whirring noise, indicating that one of the fins is broken or vibrating owing to a damaged bearing.

What temperature causes the radiator fan to activate?

The engine determines the temperature at which the radiator activates. This can be 180°F (83°C), 200°F (95°C), or even 230°F (110°C). Keep in mind, however, that the coolant temperature at the radiator fan switch is not the same as the coolant temperature sensor, which provides data to the dashboard temperature gauge.

What Does a Failing Alternator Sound Like?

A failed alternator might produce a grinding or low-frequency humming noise, suggesting that the bearing is worn out, or a buzzing sound that increases with engine speed, indicating the faulty voltage regulator. If the alternator bearing seizes, you will frequently hear the belt screeching.

Your car’s brakes should respond quickly and effectively when you press the brake pedal to stop or slow down. If your car has an Anti-Lock Braking System (ABS), you may sometimes notice that the brake pedal goes to the floor or feels mushy. Having difficulty controlling the vehicle can be alarming and dangerous, as it can make it harder for you to avoid collisions. But Can Abs Cause Brake Pedal To Go To The Floor?

A sinking brake pedal is an extra cause for concern, considering the potential consequences of any brake problem. It is imperative to dive in and solve the issue before continuing to drive with brakes you are unsure of.

In this article, you’ll learn the four most common reasons why your brake pedal goes to the floor, along with some helpful tips. Further, we will also discuss Can Abs Cause Brake Pedal To Go To The Floor?

It’s time to get started, so let’s begin.

How Do Brakes Work?

You can prevent brake failure by understanding how your brakes work:

- By pressing on the brake pedal, you create a mechanical force that is amplified by the brake booster.

- In this case, the hydraulic pressure is converted from mechanical force to hydraulic pressure by the master cylinder.

- Your master brake cylinder then presses hydraulic brake fluid into your brake lines and hoses, which carry it to the wheels.

- As the brake fluid pressure increases, the caliper piston presses the brake pads against the brake rotors.

- In drum brake vehicles (usually the rear brake), the brake shoes, rather than pads, are pressed against the brake drum by a wheel cylinder.

What is ABS?

An Your car’s anti-lock brake system (ABS) prevents the wheels from locking up when you brake. The result can be a loss of steering control and a longer stopping distance.

Using sensors that monitor wheel speed and other factors, ABS modulates brake pressure independently for each wheel. There are valves, an electric control unit, a pump, and wheel speed sensors in this unit. Learn more at here.

How Does ABS Work?

A car without ABS experiences friction when the brake pads squeeze against the rotors, slowing down the wheels. Overbraking or braking on a slippery surface can lock up the wheels, which means they stop rotating.

As a result, the car may skid and lose control, potentially resulting in an accident. By using a computer-controlled hydraulic system to adjust the brake pressure for each wheel, ABS prevents wheels from locking up.

When a wheel slows down too rapidly, ABS reduces the brake pressure on that wheel. Skidding is reduced because the wheel continues to rotate, allowing steering control to be maintained.

What are the Benefits of ABS?

Among the benefits of ABS in braking systems and vehicles are:

1. Performance Improvements in Braking

With ABS, the driver is able to stop the vehicle more quickly and safely, reducing the stopping distance.

2. Stability enhancements for vehicles

When driving on wet or slippery roads, ABS helps the driver maintain control of the vehicle.

3. Confidence increased among drivers

The driver gains more confidence and reduces the risk of an accident with ABS, as it provides a more predictable and stable braking experience.

4. Wear and tear on tires reduced

The tires may last longer because ABS prevents the wheels from locking up and reduces skidding and sliding.

5. Improved steering control

ABS allows the driver to maintain steering control of the vehicle during hard braking, essential for avoiding obstacles.

6. An overall improvement in safety

Having ABS on your vehicle can help prevent accidents and reduce the severity of injuries in the event of a collision. Most countries now require ABS on all new vehicles.

What are the Symptoms of Brake Pedal Going to the Floor?

The following symptoms can occur when the brake pedal pressed to the floor:

1. A spongy or soft brake pedal:

Air in the brake lines can cause the brake pedal to feel soft or spongy when you press down on it. It can also be a leaking brake fluid or worn brake pads.

2. Light on the brakes:

In the event that you see a brake warning light on your dashboard, this may indicate that there is a problem with your brakes.

3. The brakes are not responding:

Whenever you press down on the brake pedal, your car does not slow down or stop as expected, this is a very dangerous situation. Your brakes may be having a serious problem if this happens.

Other Signs of Brake Trouble

Besides these problems, you may also notice other signs of brake problems that require immediate attention. A car with brake problems is never a good idea to drive. Any problem with your brake system could prevent you from stopping your vehicle. There are also other signs of brake trouble, such as-

- An ABS or brake warning light on the dashboard

- Noises such as grinding, scraping, or squealing

- A burning chemical smell or a smell coming from the carpet

- Whenever you brake, you pull to one side

- If you brake, you may feel a vibration or wobble

- The brakes are emitting smoke

When your brakes squeal, they’re overheating and on the verge of failure. You should pull over your vehicle immediately if you suspect your brakes are too hot.

Can Abs Cause Brake Pedal To Go To The Floor?

Can Abs Cause Brake Pedal To Go To The Floor? ABS does not directly affect how far your brake pedal goes to the ground. It prevents the brake pedal from going to the floor instead. Further, it releases brake pressure when it detects a wheel is about to lock up, which prevents the pedal from going to the floor.

There is, however, a possibility that a malfunction in the ABS can cause the brake pedal to go down. Having a malfunctioning ABS module or hydraulic control unit can result in your brake pedal feeling spongy or soft or even going all the way down.

What Causes the Brake Pedal Going to the Floor?

In most cases, a brake pedal that goes to the floor caused by a leak in the brake system, either externally or internally. Besides the master cylinder, brake calipers, and brake lines, external leaks can occur anywhere in the system. There is likely a problem with the master cylinder if there is an internal leak. Can Abs Cause Brake Pedal To Go To The Floor? Yes, it can.

In addition to these reasons, there are other possible causes as well. Here is a comprehensive list that includes a few tips on solutions as well. The brake pedal can go to the floor for several reasons. Here are some solutions to these problems.

1. The brake lines contain air

Brake pedal force transferred to brake calipers by hydraulic pressure in your car. Having air in the brake lines can prevent the hydraulic pressure from building up, causing the brake pedal to go all the way down.

Solutions

Breathing your brakes will remove any air that may be present in the lines.

2. Leak in brake fluid

Leaking brake fluid is another potential cause of a brake pedal going to the ground. Whenever there is a leak in the brake lines or any of the brake components, you lose a lot of brake fluid and your brake pedal will feel spongy.

Solutions

- The first step is to locate the leak’s source. The brake line may damaged, the caliper or wheel cylinder may be leaking, or the brake hose might torn.

- Secondly, replace the damaged component or repair the leak, and then bleed the brakes to remove any air.

3. Damaged brake pads

It is possible for your car’s brake pads to wear down, resulting in a spongy or soft brake pedal. As a result of worn brake pads, the brake pedal may go right to the floor if there is not enough friction.

Solutions

- Step 1. If the brake pads are worn, replace them.

- Step 2. Check the brake calipers to ensure they are working properly.

4. A defective master cylinder

In the brake system, the master cylinder is responsible for generating the hydraulic pressure that is needed to stop the car. Having a faulty master cylinder or a worn one can result in the brake pedal going down to the floor.

Solutions

- Ensure that the master cylinder replaced with a new one. The 788 inch bore master cylinder is our pick.

- Below is a video that will show you how to fix a sinking brake pedal.

How Can ABS Affect Brake Pedal Feel and Performance?

It is true that ABS can enhance braking performance in many situations. But it can also introduce some challenges that affect the feel and performance of the brake pedal. When air trapped in the brake lines or when the ABS module malfunctions, the brake pedal can feel spongy or low. A spongy brake pedal indicates that there is a delay in building up pressure in the brake system, resulting in reduced stopping power and driver confidence.

When the ABS module fails to activate or modulate the brake pressure properly, a long stopping distance or increased pedal travel may result. Many factors can contribute to this, including a faulty wheel speed sensor, damaged brake lines, worn brake pads or rotors, or a malfunctioning ABS pump or solenoid. A problem with the ABS system may indicated by the ABS warning light on the dashboard.

When Should You take Your Car in for Repair?

It’s always a good idea to have your car repaired as soon as possible if your brake pedal goes all the way down.

As your foot presses your foot onto the brake pedal, the brake fluid transfers the pressure from the pedal to the calipers, which squeeze the brakes.

In order to ensure the safety of yourself, your passengers, and other road users, you should investigate the problem right away. Basically, putting off this task until it’s too late is not a good idea!

Nevertheless, you can do it yourself if you wish. However, someone unfamiliar with brakes should not attempt this, as incorrect work can worsen the situation. You should seek professional assistance if you feel uncomfortable doing this yourself.

Can You Drive When the Brake Pedal Goes to the Floor?

You should never drive a vehicle that has a brake pedal that sinks to the floor or has difficulty achieving pressure. There is a serious brake problem here that needs to addressed and repaired as soon as possible. It would be highly dangerous to neglect doing so and pose severe safety risks.

What Should You Do If Your Brake Pedal Goes to the Floor While Driving?

Pull over as soon as possible and stop applying gas. When you are in an emergency situation, do not simply yank on the brakes.

You should downshift to use engine braking and apply your emergency brake only after you have completely stopped. You should then contact a towing company or mobile mechanic to inspect and repair your vehicle.

The risk of injury to yourself and others is too high if you continue driving if you are experiencing brake problems. Moreover, you probably won’t be able to get insurance coverage if you are negligent.

Let’s examine how your brake system works in more detail since we briefly discussed brakes.

How Much Will this Cost to Get It Fixed?

In general, a broken brake pedal can cost anywhere from $100 to $600, depending on the extent of the damage and the type of car. It is recommended, however, that you have a qualified mechanic evaluate the problem for an accurate estimate.

Therefore, it’s difficult to determine which cause would cost the most to fix. You’re probably looking at about $200 to £300 if there is brake fluid leakage from the caliper, rubber lines, or rusted brake lines.

The brake master cylinder needs to replaced, and you don’t want to go with the cheapest one. As a result, you can expect to spend about $100 to $150 for labor and $150 to $250 for the part itself.

In this case, you would only have to pay for the work of aligning the brake shoes, which could cost up to $150. The cost could quickly rise to a few hundred dollars if the brakes damaged.

Keeping in mind that these are only estimates, and the final cost can vary depending on many factors, such as location, quality of parts, and who performs the work.

What are the best ways to take care of the ABS in your car?

Keeping your anti-lock braking system (ABS) in good working order is essential for safe and efficient braking. The following tips and steps will help you maintain your ABS:

1. Performing regular inspections:

Keep an eye on the ABS warning light on your dashboard periodically. The system may be malfunctioning if it remains illuminated. You should have it checked by a professional.

2. Fluid for brakes:

Your car’s brake fluid should be at the recommended level and in good condition. It is common for brake fluid to absorb moisture over time, which can affect the performance of the ABS system. Your car’s owner’s manual should tell you how to replace the brake fluid.

3. Maintenance of tires:

Ensure that your tires are properly inflated and that their tread depth is adequate by keeping them at the recommended pressure. To function correctly, ABS relies on wheel speed sensors, so tire condition is vital.

4. Maintain clean sensors:

It is essential that the ABS system has wheel speed sensors. Make sure they are clean and free of debris and corrosion. If necessary, gently clean them with a soft brush or cloth.

5. Inspection of brake pads and rotors:

Keep your brake pads and rotors in good condition by inspecting them regularly. It is possible for worn brake components to affect ABS performance. Brake pads and rotors should replaced as needed.

6. Diagnostic scans for ABS:

When your ABS warning light comes on, have it checked by a qualified mechanic who has diagnostic equipment. To pinpoint the problem, they can retrieve error codes from the ABS control module.

7. Brake softly:

If possible, avoid slamming on the brakes. It designed to prevent wheel lockup during hard braking, but excessive use can damage the system.

8. Be cautious when driving:

To avoid activating the ABS, drive safely and maintain a safe following distance.

Final Thoughts: Can Abs Cause Brake Pedal To Go To The Floor

Now you have some idea on Can Abs Cause Brake Pedal To Go To The Floor. It’s a nightmare to find your brakes without hydraulic pressure. When this happens, you will usually be able to figure out the cause if you know the most common causes. Despite the fact that you might need a professional to fix it, it isn’t a major repair. The cost shouldn’t be anything more than a necessary expense considering the consequences.

Read more of our articles here.

FAQs

How does ABS work in a vehicle?

ABS is an acronym for Anti-lock Braking System. During hard braking, this safety feature prevents wheel lock-up. While braking, ABS modulates brake pressure to each wheel independently to maintain steering control.

Is it possible for ABS to cause the brake pedal to go to the floor?

ABS does not cause the brake pedal to go to the floor on its own. It helps maintain control during hard braking by preventing the wheels from locking up. Other brake system problems usually cause the brake pedal to go to the floor.

How can a malfunctioning ABS sensor affect the brake pedal?

There is a possibility that a malfunctioning ABS sensor can cause a brake pedal problem. The ABS system may forced to activate unnecessarily if an ABS sensor fails. This may affect brake pedal feel. It is not the primary cause of a brake pedal going to the floor, however.

If my brake pedal goes to the floor, what should I do?

For safety reasons, it is crucial to address the issue immediately if the brake pedal goes to the floor. Immediately stop driving the vehicle and take it to a qualified mechanic or repair shop for an inspection and repair. Driving with a brake issue can be extremely dangerous.

Is regular maintenance able to prevent brake pedal issues, including ABS issues?

Brake fluid flushes, brake pad inspections, and proper care of ABS sensors can help prevent brake pedal problems, including ABS problems. Your brake system can operate correctly with routine maintenance.

If you are late for work, receiving an error message from your chassis control system can be frustrating. Pressing the Start Engine button usually causes it to appear. If your car is acting up, you might wonder what’s wrong with it. So, How to fix Chassis Control System fault?

Nevertheless, it isn’t immune to problems like any other part of your vehicle. You can avoid unexpected troubles in the future by understanding these issues, their causes, and how to fix them.

Nissan Rogue and other cars with this technology commonly experience chassis control system errors. Any of the three systems can be affected by a fault or problem detected by the chassis control module. These systems include active trace control, active engine brakes, and active ride control.

This guide will give you a better understanding of How to fix Chassis Control System fault; the common problems it encounters, and, most importantly, how to fix them.

What Does Chassis Control Mean?

The chassis control system is one of the features that Nissan Rogue or X-Trail V-Series owners appreciate. As a result of Nissan’s research, the chassis control system is designed to provide a smooth driving experience for the driver while maintaining maximum passenger safety. How does the chassis control system work? In rough terrain, the chassis control is essential to the safety of your vehicle because it collects data about wheel speed, acceleration, G-forces, etc… which prevents too much pressure on the car.

In recent years, chassis control systems have undergone much development thanks to advanced technologies. As the automotive industry advances technologically, chassis control systems are becoming increasingly sophisticated so that driving and turning can be made more smooth. Three leading technologies make up an active chassis control system:

1. Active Ride Control

Depending on the road or terrain conditions, this system will automatically brake and adjust traction to help the car drive smoothly and smoothly on uneven roads. In addition to reducing vibrations on the passengers, the brake system creates a little impact force that does not slow down the vehicle, only allowing the shock absorber to absorb the impact force faster. Additionally, the sensors detect changes in wheel speed to change the engine torque, allowing the vehicle to maintain a steady speed.

2. Active Engine Brake

When cornering or braking, this safety feature assists the driver. As a result of monitoring the vehicle’s speed, steering, and braking systems, the engine braking level will be increased or decreased according to the vehicle’s speed. A driver can reduce the force on the brake pedal with this extra support, which will help smooth driving and make it safer for everyone.

3. Active Trace Control

Using this system, the driver gains more confidence when cornering by adjusting braking force according to steering level, speed, and braking force due to emergency turns or entering or separating highway lanes. When driving the Nissan Rogue at high speeds, over 80 km/h, many Nissan Rogue owners stated that they are very confident; the car turns smoothly at high speeds every time.

The chassis control system combines these three technologies to provide a confident driving experience, as well as a comfortable ride for all passengers. Simply by reading these words, it is difficult to grasp the significance of this system.

What are the Benefits of Chassis Control System?

The chassis control system is a modern technology in Nissan Rogue and select Nissan cars. It has many benefits on all types of roads that improve your driving experience. When the chassis control is activated, a flash will appear on the information display. Here are some of the benefits you enjoy at that time.

1. Improved rider comfort

As a result of the chassis control system in the Nissan Rogue, passengers are able to enjoy better cabin comfort. The system reduces vibrations and up-and-down movements regardless of the road conditions. During cornering and heavy braking, the driver and passengers will not feel thrown out of their seats.

You can control the car with the chassis control system in order to make gentle movements and keep it stable.

2. Confidence among drivers

Driving on uneven country roads can be challenging because stabilizing the car can be difficult. The ability to negotiate sharp bends is also a skill that most drivers lack. You can remain confident knowing you have an assistant behind the scenes when the chassis control system is active.

3. Longer tire life

Controlling the chassis ensures the transaxle’s stability, ensuring even tire tread wear. The tire would only be able to take weight and pressure from one side, especially on rough roads. It is this unbalanced wear that leads to premature tire failure. In general, the chassis control system makes it much easier to get the most out of your tires.

What Is the Chassis Control System Fault?

In order to understand the chassis control error, we need to dig deeper into the role that this system plays in Nissan cars. A new technology specific to Nissan is the chassis control system. The system includes active engine braking, active trace control, and active ride control.

Sensors like wheel speed sensors provide data to the chassis control system. Additionally, it receives information regarding yaw rate, g-forces, and driving forces from steering, acceleration, and braking. This data is then used by the engine control unit (ECU) to control engine braking and transmission systems to improve driving performance. As a result, the technology enhances cornering, braking, and your comfort behind the wheel.

If there is a fault with the chassis control system, an error message appears on the message center. Among these are active ride control systems, active engine braking systems, and active trace control systems. Almost every Nissan Rogue or other model with this technology suffers from this problem.

What are the Common Symptoms of a Chassis Control System Error?

When there is an error with the chassis control system, your car usually won’t remain silent. In order to take early action, you need to be aware of the symptoms that it will use to communicate with you. The following are some common signs that your chassis control system may have a problem:

1. Noisy sounds

A clunking, squeaking, or knocking sound while driving, especially when turning or going over bumps, may indicate something wrong with your chassis.

2. Issues with steering

You may have a problem with your car’s chassis if you have steering problems, such as stiffness in the steering wheel or the vehicle pulling to one side.

3. The uneven wear of tires

A chassis control system ensures an even distribution of weight throughout your vehicle. You may notice uneven or rapid tire wear if there is a problem.

4. The ride quality is poor.

An issue with the suspension, which is part of the chassis system, could be causing your car ride to feel bumpier or less comfortable than usual.

5. Indications of damage

It is possible for the problem to be visually apparent at times. In some cases, the frame or suspension components of your vehicle may appear sagging or damaged.

What Are The Reasons For A Chassis Control System Error?

A chassis control system can sometimes malfunction, just like any electronic system or vehicle component. What are the reasons for this? Here are some possible solutions for how to fix the chassis control system error caused by a faulty chassis control system:

1. A loose connection between the battery and the device

There will be an effect on the current if the car terminal is loose. Having less power going to the electrical systems will lead to faulty electrical parts and sensors in the car, including the chassis control system. Your dashboard will display a warning light at that point.

This error can be resolved by tightening the battery cable if a loose battery connection is responsible. A driver who knows how to switch a wrench or screwdriver can easily tighten the positive or negative cable of their battery connection. To tighten the connection, there will usually be a nut attached to the battery terminal. You can turn this nut as needed.

2. Dead and dirty battery

Battery corrosion or dirt can build up over time, or your battery may be dying. You may also notice that your vehicle has problems starting or with electrical components, especially your chassis control system.

As a result, this system will no longer function and display a warning notification on the dashboard. Cleaning solutions (baking soda) can be applied to the car battery to remove corrosion after rinsing.

Be sure to reconnect the cables after you have cleaned your car battery after disconnecting them.

You can revive a dead battery by following these steps:

- You may be able to jumpstart your vehicle with the help of a second battery, a battery booster, or a jumper cable. Don’t shut off your car engine because the battery won’t accept a charge at that point.

- Distilled water may flood the plates completely when the electrolyte level is low and allow a slightly wider reaction area when the electrolyte level is low. The motor may be able to rev a few more times with this change. Aspirin or Epsom salt can also be used to revive a battery, in addition to distilled water.

- Having a dead car battery prevents the engine from starting, let alone the chassis control system from functioning.

There is usually a way to revive a dead car battery – at least temporarily – so that you can keep driving. Nevertheless, it is inevitable to replace your battery sometimes, even if it can be revived.

3. Failure of the ABS sensor

When you brake, your car’s ABS sensors and module work together to keep it stable. Because they measure the wheel speed, ABS sensors are also known as wheel speed sensors.

A wheel rotation and speed sensor monitors the wheels’ rotation and speed. The ABS sensor cannot provide data to your chassis if it is not functioning, so an error can occur in your chassis control system. The ABS sensor may need to be repaired or replaced to fix this problem.

4. Issues with ground lead

When the ground lead has some faults or shows an error sign, the chassis control cannot operate. Your car’s ground lead is the connection between the minus battery terminal and the chassis.

A wire like this can be easy to overlook, but it plays a crucial role in the entire electrical system of your car. The ground cable of this battery conducts all the current flowing in your vehicle.

Your car will have electrical problems if you don’t have a good ground lead, and the chassis control will malfunction. Having these issues won’t be just a minor inconvenience since they will affect the operation of your vehicle. Finding and replacing the defective ground lead with a fresh one is the best solution in this situation.

5. Wiring harness with a defect

In a wiring harness, power and information are transmitted through wires. Besides being an insulating tube, it contains cables and wires that connect various electrical and electronic components of your car.

In an organized manner, wires can pass through it. Your car will not start if the chassis fails to send commands to other components due to defective wires. The defective wires need to be found and fixed.

How to Fix Chassis Control System Fault?

As soon as you’ve diagnosed the problem, you can begin addressing it. But How to fix Chassis Control System fault? The following are some common issues you might encounter and how to fix them:

1. Fixing Suspension Issues