General Motors produces the Chevrolet Silverado, a full-size pickup truck. It was introduced in 1999 and has since replaced the Chevrolet C/K line. However, there are several problems related to the fuel injectors. Hence Useful Guide to Chevrolet Silverado Fuel Injector Issues are required for the customers to troubleshoot the problems.

Numerous trims and options are available for the Silverado. A wide variety of body styles are available, including regular, double, and crew cabs.

Additionally, it comes with a variety of engines, such as a 4.3-liter V6, 5.3-liter V8, and 6.2-liter V8. With other full-size pickup trucks, it is in competition. For instance the Toyota Tundra, Ram 1500, and Ford F-150.

Despite being the most popular car in the country, the Chevy Silverado. There won’t be any smooth rides in this car. The Silverado has many problematic model years. The Silverado may experience issues over time, just like any other vehicle.

Silverado owners frequently report a few problems. Among them are issues with the Malibu cruise control, the diesel tuners, the AC, the trailer brake system, and the fuel injectors. Any car can experience faulty fuel injectors, including the Chevy Silverado.

Let’s have a look at some useful guide to Chevrolet Silverado fuel injector issues-

What Are Fuel Injectors?

A fuel injector sprays fuel into an engine using electronic valves that can open and close many times per second. For optimum combustion and efficiency, they have an atomising nozzle that distributes fuel evenly.

Engines powered by injectors run more efficiently and emit fewer pollutants than those powered by carburettors.

There is usually one fuel injector per cylinder in a car. You will most likely have four fuel injectors if you drive a car with four cylinders.

How Do Fuel Injectors Work?

The fuel injector controls the amount of fuel delivered to the combustion chamber, making sure the right amount is injected at the right time. Each cylinder contains a fuel delivery system that ensures responsive power output and maximum efficiency at the exact moment and quantity.

- Through the fuel lines, the fuel pump delivers petrol or diesel to the injectors.

- Fuel is sprayed into the combustion chamber at the right time by the ECU (engine control unit).

- Through the nozzles, pressurised fuel is sprayed into the combustion chamber when the ECU activates the injector. Small nozzles allow fuel to be atomised, which results in a more efficient burn.

What are the Features of the Chevrolet Silverado?

A full-size pickup truck, the Chevrolet Silverado belongs to the Chevrolet brand. It also offers some exclusive features, such as:

- Numerous powerful and effective engines are available, including 4.3-liter V6, 5.3-liter V8, and 6.2-liter V8s.

- You can choose four-wheel drive for enhanced off-road performance.

- There is a lot of storage space and room for six people in this spacious interior.

- The features of modern technology are easily accessible. There are rearview cameras, lane departure warnings, and forward collision warnings, for instance.

- Each trim level offers distinct features and options, including the WT, LS, LT, RST, LTZ, and High Country.

- Towing capacity is 12,500 pounds, which is sufficient for hauling and towing. Chevrolet Infotainment 3 is installed on this vehicle. In addition, Apple CarPlay and Android Auto are supported, as well as a Bose premium audio system.

- Depending on the trim package and model year, the aforementioned list may vary.

What are the Problems with Fuel Injector of Chevrolet Silverado?

1. Less Fuel Mileage

You might notice a decrease in fuel economy in your Chevy Silverado if you have a fuel injector problem.

As a result of clogged or dirty fuel injectors, the engine can work harder and consume more fuel due to the incorrect amount of fuel being delivered to it.

Track the fuel consumption of your vehicle as you troubleshoot this issue. You might have a problem with your fuel injectors if you notice a sudden increase in fuel consumption.

The most common solution to this problem is to clean or replace the fuel injectors. An injector cleaner can be used, which is added to the fuel tank and cleans the injectors during engine operation.

A professional cleaning or replacement of the injectors might be needed if this doesn’t work.

2. Knock/Detonation

You’ll hear a knocking sound when the fuel in the cylinders detonates in multiple places at once, also known as a detonation.

A fuel-to-air ratio that is incorrect can be caused by the fuel injectors not delivering the right amount of fuel.

In order to resolve this issue, it is necessary to pay attention to what is being said. It is possible that your fuel injectors are malfunctioning if you hear a knocking or pinging sound when your engine is under load.

You may need to clean or replace the fuel injectors in order to fix this issue. The vehicle should be inspected by a professional mechanic if the problem persists.

3. Clogged Or Dirty Injectors

Injectors that are clogged or dirty can cause a variety of problems, from reduced performance to misfiring engines.

The fuel-to-air ratio is disrupted as a result of the injectors not being able to deliver the necessary amount of fuel.

Observing the performance of your vehicle is essential to troubleshooting this problem. You might have a dirty or clogged injector if your Silverado struggles to accelerate, idles roughly, or misfires.

Clean your fuel injectors with a fuel injector cleaner if this issue persists. It may be necessary to replace or clean the injectors if the problem persists.

4. Unresponsive Injectors

Another common problem is an unresponsive fuel injector. Fuel isn’t delivered when it should be when injectors malfunction. Misfires or rough idling can occur as a result.

There are a number of symptoms that can be caused by this problem, making troubleshooting it difficult. It’s possible you’re dealing with unresponsive injectors if your Silverado is having performance issues.

Injectors that are unresponsive may need to be replaced. Since this requires specialized tools and knowledge, it should be performed by a professional.

5. Leaking Injectors

A leaky fuel injector can lead to increased fuel consumption, poor performance, and a strong gasoline smell. Injectors fail to close properly, resulting in fuel leaks.

When troubleshooting this issue, check for signs of a fuel leak, such as a strong gasoline smell or visible fuel on the ground.

It could also be a sign of an injector leak if the vehicle consumes more fuel than usual.

It is typically necessary to replace a leaking injector in order to fix the problem. To ensure it’s done safely and correctly, it should be handled by a professional.

6. Fuel Related Misfires

It is possible for fuel-related misfires to occur if the fuel injectors aren’t delivering the correct amount of fuel. Misfires can result from this disruption of the combustion process.

In order to resolve this issue, you will need to pay attention to how your vehicle operates.

There may be a misfire if the engine lacks power, idles rough, or the check engine light illuminates.

It is often necessary to clean or replace the fuel injectors in order to fix fuel-related misfires. In the event that the problem persists, the vehicle should be inspected by a professional mechanic.

7. Rough Engine Idling / Stalling

An excessively or inadequately delivered fuel injection can cause rough idling or stalling. Rusty idling or even stalling can result from this.

Check your Silverado’s idling performance as you troubleshoot this problem. It could be a fuel injector problem if the engine idles rough or stalls.

Injectors typically need to be cleaned or replaced to fix this problem. In the event that the problem persists after this, a professional mechanic should inspect the vehicle to rule out a more serious issue.

8. Failed Emission Test

A failed emission test can indicate a problem with the fuel injectors. An incorrectly functioning injector can lead to excessive emissions from a vehicle.

Getting your vehicle tested is the first step in troubleshooting this issue. You may have a problem with your fuel injectors if your Silverado fails an emission test.

In most cases, fuel injectors must be cleaned or replaced to fix this problem. Following this, a professional mechanic should inspect the vehicle if it continues to fail emission tests.

9. Decreased Engine Performance

Fuel injectors that do not deliver the right amount of fuel can cause engine performance to decrease. A lack of power can result from this disruption of the combustion process.

In order to troubleshoot this issue, you need to pay close attention to how your vehicle performs. An issue with the fuel injectors could be causing your Silverado to struggle to accelerate or maintain speed.

Typically, fuel injectors need to be cleaned or replaced to solve this problem. The vehicle should be inspected by a professional mechanic if the problem persists after this.

10. Increased Fuel Consumption

Too much fuel can be delivered by the fuel injectors, resulting in increased fuel consumption. Increased fuel consumption can result from the engine burning more fuel than necessary.

Track the fuel consumption of your vehicle as you troubleshoot this issue. An increase in fuel consumption without a corresponding increase in driving may indicate a problem with the fuel injectors.

Often, fuel injectors need to be cleaned or replaced in order to fix this issue. The vehicle should be inspected by a professional mechanic if the problem persists.

11. Fuel Injector Nozzle Clogging

Dirt and debris can clog injector nozzles and cause them to fail.

A malfunctioning injector can result in reduced performance or misfires because it cannot deliver the correct amount of fuel.

If you want to troubleshoot this issue, pay attention to how your vehicle performs. The clogged injector nozzle in your Silverado might be causing your vehicle to struggle to accelerate, idle rough, or misfire.

It is typically necessary to clean the fuel injectors in order to resolve this issue. It might be necessary to replace the injectors if the problem persists.

12. Engine Misfire Triggering Engine Management Light

An engine misfire can cause the engine management light to illuminate. The combustion process can be disrupted when the fuel injectors don’t deliver the correct amount of fuel.

You can troubleshoot this issue by paying attention to the dashboard lights in your vehicle. A malfunctioning fuel injector could indicate the engine management light is on, especially if performance issues accompany it.

Often, fuel injectors need to be cleaned or replaced in order to fix this issue. The vehicle should be inspected by a professional mechanic if the problem persists.

13. Car Won’t Start Easily Or At All Due To Leaky Injector

Leaky injectors could be the cause of your car not starting easily or at all. The engine cannot start because fuel leaks out of the injector, causing fuel shortages.

When troubleshooting this issue, pay attention to how your vehicle starts. Having trouble starting your vehicle or not starting at all could be the result of leaking injectors.

It is usually necessary to replace the leaky injector in order to fix this issue. A professional should handle this task to ensure it’s done correctly and safely.

What are the Symptoms of Faulty Fuel Injector in Chevy Silverado?

It is similar to the symptoms of a bad fuel pump or fuel filter when a fuel injector is malfunctioning. As a result, checking fuel pressure before changing injectors is crucial. Unless you do, you may waste your money. The injectors are reasonably priced if you do need to replace them.

Dirty | Clogged Injectors

Experiencing difficulties when certain cylinders are not getting the right amount of fuel. The engine may struggle to turn over and even fail to start.

1. Vacant Issues

You are having a fuel atomizer in the fuel injector that isn’t operating well. Your Silverado will need help with idle. That implies that the idle speed will suddenly decrease. You’ll experience a sense of impending engine failure.

2. Emissions Issues

when the correct amount of fuel is not being delivered to the combustion chamber. That suggests that the fuel/air ratio may change in the engine, which could lead to higher exhaust emissions.

3. Loss of Power

The majority of the time, you won’t be able to “feel” the engine misfire as much. But as the engine RPM increases, you will undoubtedly feel the loss of power.

4. Less Fuel Mileage

The air/fuel ratio is continuously adjusted by the engine management computer in your Silverado. Moreover, the timing for ideal combustion The fuel economy suffers when the fuel injectors aren’t working well because it can’t do that.

5. Knock/Detonation

Detonation could cause the engine in your Silverado to blow up. The worst-case scenario is without a doubt. Never disregard an engine that isn’t operating properly. If you don’t immediately address the problem, it will eventually cause more damage.

6. Leaking Injectors

Injector problems and fuel filter clogging. An injector system leak can have several different causes, one of which is a fuel pressure regulator issue. Leaking injectors can affect an engine’s performance and fuel efficiency, and in some cases, they can cause the engine to stall or not start at all.

7. Thin Oil

A fuel injector leak prevents the combustion chamber from burning all of the fuel. Any gas that is not burned and is not released as the exhaust is collected in an oil pan. When this happens, your Silverado’s engine lubrication can get so low that it will lock up. There is an odor of fuel on the dipstick.

8. The Smell of Fuel

If your engine is receiving too much fuel, your Silverado won’t be able to burn it all. As You’ll probably notice the smell of gasoline as you drive locally. For you to catch it, there will probably be too much wind on the highway.

9. Engine Locks Up

The motor will lock up if there is too much gas in the oil. Do not drive your Silverado if you have any reason to believe there is gas in your oil. Replace the oil.

How to Diagnosis Bad Fuel Injectors in Chevy Silverado?

It’s challenging to diagnose fuel injector problems. Considering that it behaves exactly like a bad coil, a dead spark plug, and an electrical issue. To fix your fuel injector, follow these steps.

- When the engine is cold, start it and let it idle for 5 to 10 seconds.

- Use only your bare hands to locate the exhaust manifold that isn’t warm as soon as possible. Avoid doing this if the engine is warm. Spray water on the exhaust manifold if the engine is hot, or wet your hands and, if you can, quickly touch the manifolds.

- On the cylinder with the cold fuel, unplug the injector connector.

- To make sure they are not corroded, inspect the injector connector’s terminals.

- Use an ohm meter or a Noid light (the majority of auto parts stores sell cheap horns) to determine whether the injector connector is powered.

- An ohm meter should be used to measure the injector’s resistance.

- Re-connect the injector connector.

- If a Noid light or ohm meter is not accessible. You can listen for injector clicks using a rubber hose or stethoscope. Place one end of the hose or stethoscope against the injector and listen for the clicking sound at the other end. By pressing a stethoscope or rubber hose against the injector, you can listen for injector clicks. Having the other end listen after that

- Remove the coil pack by disconnecting it. which, in addition to the spark plug wire, is attached to that cylinder.

- When you turn the engine on, it ought to sound the same.

- Put the spark plug away. A dry spark plug prevents the injector from delivering fuel to that cylinder. In this case, there is no problem with the injector in the cylinder if the spark plug is wet and smells like gasoline.

- Moving the suspect injector to a different cylinder is one way to make a diagnosis. If the injector fixes the issue, kudos to you. But, this can take hours to complete on some engines.

What are the common Issues with the Chevrolet Silverado?

Besides the fuel injector problem, there are also some common problems that owners of the Chevrolet Silverado have reported. Include:

- Transmission issues: Some owners have reported problems with the transmission, such as slipping gears or delayed shifting. They can diagnose the problem and recommend the necessary repairs or replacements.

- Engine problems: The issues with the engine like excessive oil consumption or warning lights appearing on the dashboard. If you are experiencing these engine problems it is best to have the engine checked very well.

- Suspension problems: Issues with the suspension like worn shocks or struts, leading to a rough ride and poor handling.

- Electrical problems: Reports of electrical system issues have been made by some owners. Like, For difficulties with power windows or door locks

- Brake problems: There could be issues with the brake system, such as premature wear or abnormal noise.

It’s worth noting that the issues mentioned above are not exclusive to the Chevrolet Silverado. These are the common issues that can happen in any car. Also, these issues may vary depending on the model year, mileage, and overall maintenance of the vehicle.

How Much Does It Cost to Replace Fuel Injectors?

You won’t need to replace your fuel injectors if you follow your car’s service schedule and replace the oil and filters regularly. After years of neglect, your injectors may be in a very sorry state, and you will need to replace them.

It isn’t common practice to replace fuel injectors, and with the right service and upkeep, there should be no reason to do so. What is the cost of replacing injectors? How does doing so benefit you?

One fuel injector typically costs about £150, but this will vary based on the age of your car and the type of injection system you have. It is not uncommon for your quoted bill to exceed this figure due to labour costs as well.

It’s worth listening to a mechanic who recommends replacing the fuel injectors. You could incur further extensive repair costs if you do not take action, resulting in further damage throughout the fuel system and engine.

Useful Guide to Chevrolet Silverado Fuel Injector Issues

Your Chevy Silverado fuel injectors require regular maintenance to avoid issues. Check out this useful guide to Chevrolet Silverado Fuel Injector Issues.

Clean the fuel injectors regularly, use quality fuel, and replace the fuel filter according to the manufacturer’s recommendations. You can follow these tips:

Use Quality Fuel

Make sure you fill up your truck with high-quality fuel from reputable gas stations. Injectors can become clogged or damaged when fuel quality is poor or contaminated fuel is used.

Regular Maintenance

Make sure you follow the manufacturer’s recommended maintenance schedule. Performing regular fuel system inspections, cleaning, and replacing fuel filters is part of this process. Keeping the fuel system well-maintained reduces the risk of injector problems.

Avoid Running On Empty

Fuel should be kept at least a quarter full in your vehicle. Injectors may be strained if the fuel pump is forced to work harder on low fuel levels.

Use Fuel Additives

If you want to keep your fuel system clean and maintained, you should use fuel additives designed specifically for that purpose.

Using these additives can prevent deposits from building up in the fuel injectors and keep them clean.

Drive Regularly

Fuel system health is maintained by regular driving. The fuel in a vehicle can degrade over time when it is not driven for an extended period of time.

If you expect not to use your truck for an extended period of time, consider using a fuel stabilizer.

Avoid Aggressive Driving

Injectors can be stressed by aggressive driving habits such as hard braking, sudden acceleration, and excessive idling. Maintain a smooth driving style and avoid unnecessary engine strain.

Inspect For Leaks

Regularly inspect the fuel system, including the injectors, for signs of fuel leaks. There is a risk of fuel leaks damaging injectors and causing other problems. Leaks should be repaired immediately if you notice them.

Address Warning Signs

Fuel injector issues can cause rough idle, poor acceleration, decreased fuel efficiency, or engine misfire. Pay attention to any warning signs of fuel injector problems.

If To diagnose and address the problem early, have your truck inspected by a qualified mechanic if you notice any of these symptoms.

Conclusion

The Chevrolet Silverado may encounter issues that can affect various components. If you encounter fuel injector problems, it is recommended to bring the vehicle to a professional mechanic or dealership for proper diagnosis and repair.

Regular engine and fuel system maintenance. Such as replacing the air filter, checking the fuel pressure, and cleaning the fuel injectors, can also prevent these problems. To prevent some of these issues from occurring. Ensure that you inspect the issues early on before they become more serious.

Keep Reading Ford 5.8 Engine Problems: Causes & Solution Explained!

FAQ

How can I use a multimeter to check injectors.?

Consequently, you’re going to get your multimeter, turn it on, and set it to ohms. This Omega horseshoe sign represents a 200 setting. When it reaches 200, too. We could examine every fuel.

A fuel injector should have how many volts, exactly?

The coil is typically powered by 12 volts in most injectors, and the driver powers the circuit by pulling it to the ground. The injector causes the voltage to decrease to almost zero when turned on. If not, it might be a sign that the injector’s injector coils are open or that a wiring harness connection is weak or open.

Can I clean the fuel injectors myself on my Silverado?

It is possible to clean fuel injectors yourself, but doing so calls for the use of specialized tools and some mechanical expertise. If you feel uneasy about the process. Seek professional help.

How much does it cost to change a fuel injector in a Chevrolet Silverado?

The price to replace a fuel injector on a Chevrolet Silverado can change based on the vehicle’s year, make, and model and the repair’s location. The price per injector can range from $200 to $600 on average, with labor costs adding another $100 to $200.

What tests do technicians conduct when testing injectors?

Technicians can evaluate the mechanical performance of a fuel injector on a spark ignition engine by using a two-channel test on an oscilloscope. Due to the design and functionality of the injector, this test is only applicable to low-pressure fuel injectors.

The Ford 5.8 liter engine, also known as the 351 Windsor, was produced by Ford Motor Company from 1969 to 1996. It is used in a wide range of vehicles, including the Ford F-150, Mustang, and Bronco. But are you aware of Ford 5.8 Engine Problems?

There are several reasons why problems may occur with the Ford 5.8 engine. Some of the most common causes include Lack of regular maintenance, Overheating, Oil leaks, Misfiring, Rough idling, Wearing out of internal parts, and overloading or overuse.

The 5.8-liter engine was famous for its durability and reliability, as well as its power and performance. It was also popular among enthusiasts for its potential, modifications, and upgrades. The 5.8-liter engine was replaced by the Ford 4.6-liter engine in the 1990s, which offered better fuel efficiency and emissions control.

Here, we’ll discuss everything about the Ford 5.8 engine, its problems, and its fixes!

The Most Common Problem With The Ford 5.8 Engine!

The common problems are listed below:

- Piston and Rod Quality Issues

- Leaking

- Lack of regular maintenance

- Overheating

- Oil leak

- Misfiring

- Rough Idling

Let’s briefly explain all these problems and the necessary fixes to avoid further damage!

Piston and Rod Quality Issues

Due to flaws in design and manufacturing, Ford 5.8L engine pistons and connecting rods caused issues for several owners. Ford 5.8L engine piston and rod upgrades are possible with the necessary equipment, some research, and some time.

Taking out the worn-out pistons and rods is the first step in installing a new aftermarket upgrade kit. To do this, you must remove the pistons from the cylinders and disconnect the connecting rods from the crankshaft. Cleaning the cylinders and connecting rod journals using a brush and an engine-safe solvent is the next step after removing the old pistons and rods.

The replacement pistons and connecting rods are the next step. Pistons and connecting rods must be installed into the engine’s cylinders. After installing new pistons and connecting rods, you must reassemble the engine and test it for leaks by turning the key.

Leaking

Inadequate or old seals and gaskets, engine block or head cracks, broken hoses, and even loosened fasteners can all contribute to leaks. If you don’t inspect, it can lead to more complications.

The oil leaked from the engine can enter the engine through the spark plugs and cause the engine to misfire. It’s recommended that you take your automobile to a mechanic, but if you’re feeling adventurous, you can try certain fixes alone.

- Inspect your engine’s hoses, seals, and gaskets as a first step. Replace them if you find any of them to be broken or leaking.

- If none of those options work, utilize auto shop tools and parts.

- Next, inspect the engine block and head for any signs of cracking.

- A sealant or a patch kit is usually all needed to fix these.

- You may need a new engine block or head if the spaces are too great.

- Last but not least, double-check every engine bolt.

- Ensure all bolts are tightened to Ford’s standards to prevent leakage.

- If your engine leaks after you’ve checked all these places, it’s time to take it in for a professional diagnosis and repair.

- If you follow these instructions and repair the leaks independently, you can avoid visiting the specialist and the associated costs.

Lack of regular maintenance

One of the main reasons for the Ford 5.8 engine problems is a lack of routine maintenance. Regular oil changes, tune-ups, and other normal maintenance should not neglect.

Because doing so can cause the engine to accumulate dirt, debris, and carbon. Which, over time, can harm internal components. Additionally, it can lead to the breakdown of the engine oil. Which might result in a loss of lubrication and worsened wear on internal components.

Checking and changing spark plugs, fuel filters, air filters, and other worn parts are all part of routine maintenance. Failure to do so may result in poor performance and decreased fuel efficiency, which may cause more significant problems.

Overheating

The Ford 5.8 engine problems have a number of typical, one of which is overheating. Overheating can cause several factors. Including a failing water pump, a clogged radiator, or a malfunctioning thermostat. A failed water pump will not be able to circulate coolant through the engine, causing the engine to overheat. A clogged radiator can cause a restriction in the coolant flow, leading to overheating. A malfunctioning thermostat can cause the engine to run too hot or too cold, also leading to overheating.

Another cause of overheating can be a malfunctioning cooling fan. Which is responsible for blowing air over the radiator to cool down the coolant.

Oil leaks

A broken oil pan gasket, valve cover gasket, or rear main seal can all cause oil leakage. These seals and gaskets are in charge of maintaining the engine’s oil level and avoiding leaks.

They are made of rubber or other materials that can deteriorate over time when exposed to high temperatures, oil, and other toxins. Oil can seep out of these gaskets or seals. When worn out or damaged, they harm the gearbox, exhaust system as well as other components of the engine.

A cracked oil pan gasket can spill from the engine’s bottom. A damaged rear main seal or a blown valve cover gasket can cause oil leaks from the top of the engine.

Read More Why Is My Jeep Wrangler Leaking Oil? Reasons Explained!

Misfiring

A damaged spark plug or ignition coil, for example, can contribute to misfiring in an ignition system. These elements are in charge of generating the spark necessary to ignite the engine’s fuel. When they break down, the engine may either not start or run poorly. Vacuum leaks and clogged fuel injectors are some potential causes.

A vacuum leak can make the engine run lean, which can lead to misfiring, and a clogged fuel injector can make the mixture rich and thus lead to misfiring.

Rough idling

The engine runs unevenly at idle and rattles or vibrates excessively. This is referred to as “rough idling.” There are a number of things that might lead to this, such as,

- Vacuum leaks: A vacuum leak can cause the engine to run lean, which can cause rough idling, poor acceleration, and a decrease in fuel efficiency.

- Clogged fuel injectors: A clogged fuel injector can cause a rich mixture and rough idling, poor acceleration, and a decrease in fuel efficiency.

- Malfunctioning mass airflow sensor: A malfunctioning mass airflow sensor can cause the engine to receive the wrong amount of air. Which can cause rough idling, poor acceleration, and a decrease in fuel efficiency.

- Ignition system: A faulty ignition component can cause rough idling.

- Incorrectly adjusted valves or timing: The valves or timing may not fix well, causing the engine to run roughly

- Worn-out internal parts: Worn-out internal parts such as worn-out piston rings, valves, and bearings can cause rough idling

To fix rough idling, it is important to identify the underlying cause of the problem and then repair or replace the faulty component.

Wearing out of internal parts

As the engine runs for kilometers, interior part wear and tear is a regular issue that can arise. As the engine operates, internal parts such as piston rings, cylinder walls, and bearings are subjected to a significant amount of wear and tear. Over time, these parts can lose their efficiency and effectiveness, leading to a variety of problems.

- Oil consumption: Worn-out piston rings can allow oil to pass by and burn, causing increased oil consumption.

- Power loss: Worn-out cylinder walls and bearings can cause power loss, reducing the engine’s ability to produce power.

- Knocking or ticking noise: Worn-out bearings can cause a knocking or ticking noise from the engine.

- Low compression: Worn-out cylinder walls or piston rings can cause low compression. Which can lead to poor engine performance.

- Excessive smoke: Worn-out piston rings or cylinder walls can cause oil to burn which can lead to excessive smoke from the exhaust.

Overloading or overuse

Another typical source of issues with the Ford 5.8 engine is overloading or overuse. Heavy towing or racing use of the car can put a lot of strain on the engine and eventually lead to issues. The engine has to work harder, which might cause internal parts to deteriorate faster.

- Power loss: Overuse can cause power loss, reducing the engine’s ability to produce power.

- Overheating: Towing heavy loads or using the vehicle for racing can cause the engine to overheat. Which can cause damage to internal components.

- Reduced fuel efficiency: Overuse can lead to increased fuel consumption and reduced fuel efficiency.

- Increased wear and tear: Overuse can lead to increased wear. And tear on internal components, such as pistons, cylinders, and bearings.

- Increased emissions: Overuse can lead to increased emissions due to the engine working harder than it’s designed to.

- To prevent problems caused by overloading or overuse. It is important to use the vehicle. Within its capabilities, avoid towing heavy loads or using the vehicle for racing.

Watch Here

Is Ford 5.8 Engine Good or Not?

On paper, the Ford 5.8L engine looked like a real winner. It was used in the 2013–2014 Ford Shelby GT500, which was one of the most powerful production automobiles in the world at the time.

The 5.8L is a V8 with a four-valve-per-cylinder valvetrain and a pair of overhead camshafts (DOHC). It has a block and a head made of metal. The engine is 5,810cc in size, with a compression ratio of 9.0:1, a bore of 3.681 inches, and a stroke of 4.165 inches.

The Eaton TVS 2300 supercharger, cold air intakes, and 60 mm throttle contribute to the vehicle’s supercharged and intercooled ambition. The fuel distribution is controlled using an SPFI system.

In combination, these parts allow the Ford 5.8L engine to generate 662 horsepower at 6,500 rpm and 631 lb-ft of torque at 4,000 rpm. It has an electronic system that allows for over-revving up to 7,000 rpm for up to eight seconds at a time, while its usual redline is at 6,250 rpm.

The engine, combined with the Shelby GT500’s incredible engineering, allows the car to accelerate from 0 to 60 mph in 3.5 seconds and reach a high speed of 200 mph. It surprised expectations by returning 15 mpg in the city and 24 mpg on the interstate, despite being a performance-oriented power unit.

Conclusion: Ford 5.8 engine problems & solutions.

One of the ways to diagnose the problem is by using an OBD (On-Board Diagnostics) scanner. You can connect this device to the vehicle’s computer to read diagnostic trouble codes. And provide information about the vehicle’s performance. It can help you identify the issue and understand what you must do to fix it.

It’s important to remember that some problems can be complex and may require multiple steps to diagnose. So it’s always best to consult a qualified professional to get a proper diagnosis.

Keep Reading Ford 400 Engine Problems & Solutions

FAQs

How many cubic inches is 5.8 ford engine?

The 5.8-liter Ford engine has a displacement of 360 cubic inches.

What is ford’s strongest engine?

As of 2023, the Ford Shelby GT500’s 5.2-liter supercharged V8 engine is considered to be the strongest engine produced by Ford, producing over 700 horsepower.

Which Ford is the best for fuel?

The specific Ford model that is the best in terms of fuel efficiency depends on a number of factors such as the type of vehicle (sedan, SUV, etc.), the engine size, and the specific trim level. However, some of the more fuel-efficient Ford models include the Ford Fusion Hybrid, Ford C-Max Hybrid, and the Ford EcoSport.

What is Ford’s fastest engine?

As of 2023, the fastest engine produced by Ford is the 5.2-liter supercharged V8 engine found in the Ford Shelby GT500, which can produce over 700 horsepower and reach a top speed of over 180 mph.

Which Ford car has the highest mileage?

Some Ford models known for their high fuel efficiency and good mileage include the Ford Fusion Hybrid, the Ford C-Max Hybrid, and the Ford Focus Electric. These vehicles can achieve gas mileage in the high 40s to low 50s in miles per gallon, depending on driving conditions and other factors.

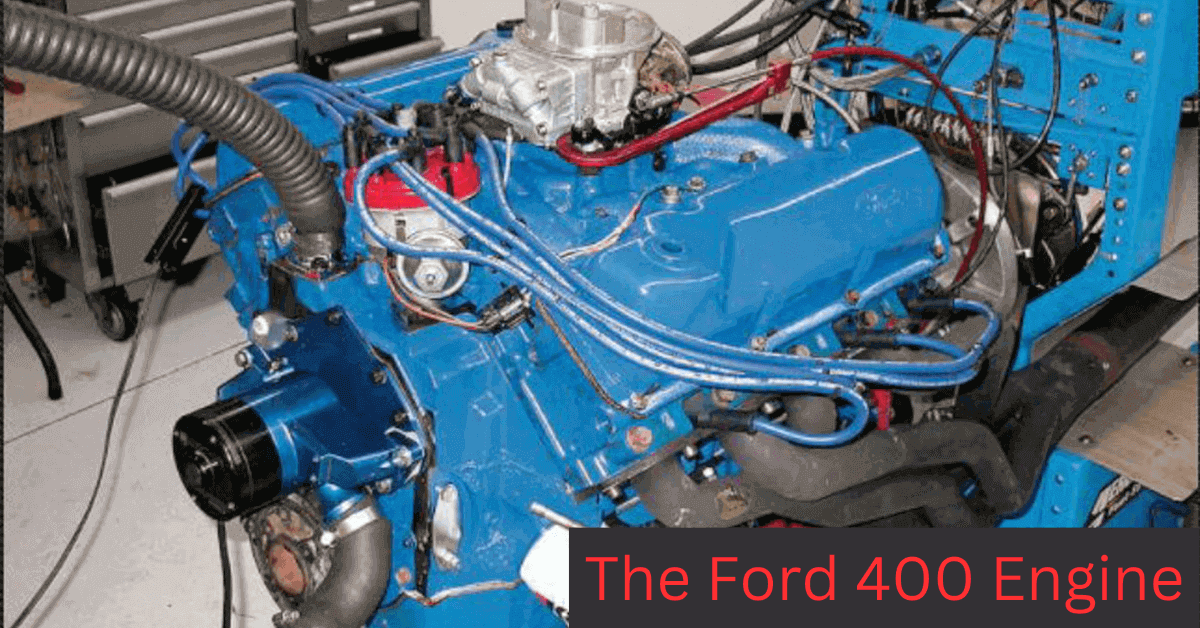

The Ford 400 engine is a V8 engine that was produced from the 1970s until the 1980s. Some common Ford 400 engine problems are overheating, low oil pressure, and valve train noise for instance.

Potential solutions to these problems include checking and replacing the thermostat, checking and replacing the oil pump, and checking and replacing the valve lifters.

However, the engine may also have cylinder heads, gaskets, and timing chain issues. Also, due to its design flaw of having excessive deck clearance, the engine may have issues with the compression ratio being too high, leading to problems with the combustion chamber and poor fuel economy.

Let’s go over the Ford 400 engine problems and solutions.

Ford 400 overheating issues

It is vital to make sure of the following things to address Ford 400 engine overheating problems:

Coolant levels: Make certain the coolant levels are at the proper level and are not low. Check for system leaks if the coolant levels are low and fix them as necessary.

Radiator and hoses: Inspect the radiator and hoses for damage. Change it, if they break or leak.

The thermostat controls how much coolant flows through the engine. A faulty thermostat can cause the engine to overheat. Check if it needs to replace.

Water pump: The water pump is responsible for circulating the coolant throughout the engine. If it is failing or not working well, replace it.

Fan clutch: The fan clutch controls the engine’s cooling fan speed. If it is faulty, it can cause the engine to overheat. Check and replace if necessary.

Timing: Check the engine’s timing, if it’s off, it can cause overheating.

Ford 400 poor performance

To solve the poor performance of the Ford 400 engine problem, it may be necessary to check the following:

Ignition system: Check the ignition system for any issues. This includes the distributor cap, rotor, spark plugs, and ignition wires. It’s necessary to replace any worn-out or broken parts.

Gas: inspect it for any problems. The fuel filter, fuel pump, and carburetor are all part of this. It’s necessary to replace any worn-out or broken parts.

Cleaner: Improper performance of the engine might result from an airflow restriction caused by a dirty or clogged air filter. Replacing a blocked air filter is essential.

Time: Examining and modifying the timing can make the Ford 400 engine run more smoothly. The timing includes both the opening and closing of the engine’s valves as well as the timing of the ignition spark.

Compression: A compression test is a simple way to check the health of the engine, it measures the amount of pressure in each cylinder when the starter motor is cranking the engine over. If the compression is low in one or more cylinders, it can indicate a problem such as worn rings, a damaged valve, or a blown head gasket.

Exhaust system: The exhaust system’s main function is to remove the harmful gases created during the combustion process from the engine. If the exhaust system restricts or leaks, then it can cause backpressure, which can lead to poor engine performance and fuel economy.

Vacuum leaks: To check for vacuum leaks on the Ford 400 engine, you can use a vacuum gauge or a vacuum pump, which you can buy or rent from an auto parts store. The vacuum gauge is connected to the intake manifold, and the engine is started.

Oil leak in Ford 400 engine

There are several causes of oil leak in the Ford 400 engine, including worn or damaged gaskets and seals. Some common areas where oil leaks can occur for instance:

Oil pan gasket: You identify the oil pan gasket by a puddle of oil on the ground under the vehicle, or by oil dripping from the bottom of the oil pan.

The oil leak may also lead to a burning oil smell. It is also important to make sure that the oil pan is well sealed and tightened to prevent future leaks.

Valve cover gasket: Oil leaks can occur because of deterioration or wear to the valve cover gasket, which seals the valve cover to the engine head. If oil is dripping from the top of the valve cover or there is a burning oil odour, then you have a valve cover gasket leak.

However, it is necessary to remove the valve cover from the engine to repair a valve cover gasket leak.

Rear main seal: The rear main seal sits between the engine block and the crankshaft, and can become worn or damaged, causing oil to leak.

Scheduling cover gasket: The timing cover gasket, seals the engine block and timing cover together, allowing oil to leak.

Oil tank adapter: Oil may flow if the oil filter adapter if torn or lose.

However, finding the precise location from which the leak is coming is necessary to remedy an oil leak.

Read More Why Is My Jeep Wrangler Leaking Oil? Reasons Explained!

Carburetor problem in Ford 400 engine

A range of Ford 400 engine problems, such as poor engine performance, stalling, and trouble starting. Typical issues with carburetors that document include:

Clogged carburetor: Over time, dirt, and debris can accumulate in the carburetor, causing it to become clogged. This also can restrict the flow of fuel to the engine, causing poor performance.

Carburetor jets worn out: Further, the carburetor jets are in charge of supplying fuel to the engine. They might not be able to distribute the right amount of fuel.If they are unclean or worn down, then this would make the engine perform poorly.

Leaking carburetor: The carburetor can develop leaks, either at the gaskets or at the needle valves. This can cause a loss of fuel, resulting in poor engine performance indeed.

Choke issues: When the engine is cold, the choke regulates how much air gets into the carburetor. If the choke is not working well, then the engine may have difficulty starting or may stall.

In order to fix carburetor problems, you need to diagnose the specific issue. Visual inspection and diagnostic testing also can be used to accomplish this.

Timing problem

Timing issues with the Ford 400 engine can lead to a number of issues, such as poor engine performance, stalling, and trouble starting. Further, there have been reports of many typical timing difficulties, including,

1. Timing Chain Extend: The timing chain may stretch with time, resulting in incorrect engine timing. This can also cause the engine to stall or run poorly.

2. Timing Chain Tensioner Failure: The timing chain tensioner is responsible for maintaining the proper tension on the timing chain. If it fails, then the timing chain can become loose, causing the engine timing to be off.

3. Timing Chain Guides Wear Out: While the timing chain guides keep the chain running smoothly. If they wear out, then the chain can jump the timing, causing poor engine performance and damage.

4. Timing Gears Wear Out: The timing gears keep the engine’s timing in sync. If they wear out, then the engine timing throws off, causing poor engine performance and damage.

Let’s see Ford 400 engine rebuild

Final Words

It is very important to regularly maintain and service the engine to prevent these problems and ensure the proper functioning of the vehicle.

However, by keeping up with regular maintenance, you can extend the life of the engine and prevent costly repairs in the future. It’s also essential to have a professional mechanic diagnose the issue and fix it if any issues arise.

FAQs

Is the Ford 400 a good engine?

The Ford 400 engine is a durable and reliable engine indeed. It was also well known for its high-performance capabilities and was used in a variety of Ford vehicles, including trucks, vans, and muscle cars. It was also known for its ability to handle high horsepower and torque, making it a popular choice for hot rods and street machines.

What years are the Ford engines to avoid?

While the Ford F-150 trucks with the Triton V8 engine from the 2004 to 2007 model years had known to have significant reliability issues.

These model years are generally considered to be some of the least reliable Ford F-150s and are generally recommended to avoid by many experts and consumers.

How much HP does a Ford 400 have?

The Ford 400 engine was produced with different horsepower ratings depending on the year and model. However, the factory horsepower rating for the Ford 400 engine ranges from around 185 horsepower to well over 300 horsepower.

How many liters is a Ford 400 engine?

The 400’s 4.0 in (102 mm) bore and stroke gave it “square” dimensions indeed. Ford advertised the engine as having 400 cu in., but it actually had 402 cu in (6.6 L). Ford engineers also boost the block deck height to 10.297 inches as opposed to the 351C’s 9.206 inches to suit the larger stroke.

How do I identify a Ford 400 engine?

For the Ford 400 engine, you can find the casting number on the passenger side of the block,also near the bell housing. The most common casting numbers for the Ford 400 engine are “D1AE” and “D1VE.” It’s worth noting that some Ford 400 engines may have been rebuilt or modified, so the casting number may not match the original engine.

RELATED:

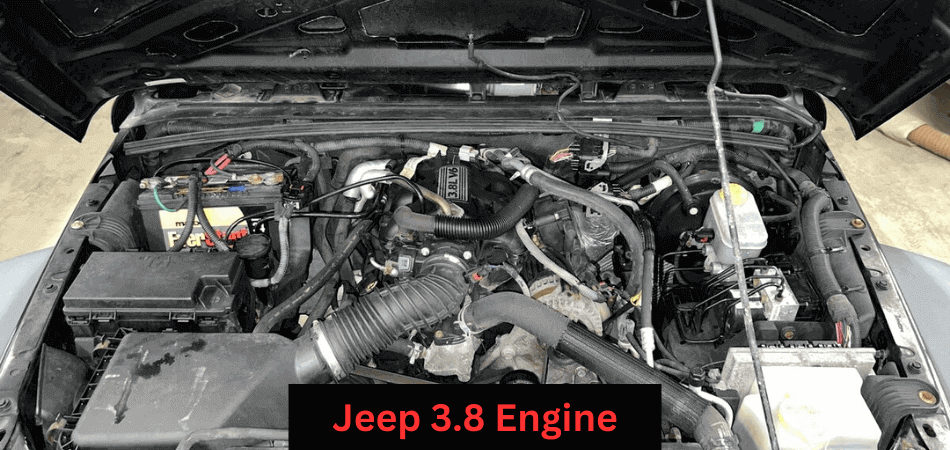

The 4.7-litre HO (High Output) engine is a V8 engine. Chrysler produced it for use in several of its vehicles, including the Jeep Grand Cherokee. This engine provides increased power and performance compared to the standard 4.7-litre engine. However, there are several Jeep 4.7 Ho engine problems arised over the course of years

The 4.7-litre HO engine produces a power output of 305 horsepower and 334 lb-ft of torque. It features a DOHC (Double Overhead Cam) design and utilizes a VVT (Variable Valve Timing) system to optimize performance. Additionally, it uses a 32-valve design with a 10.5:1 compression ratio. It was available on the Jeep Grand Cherokee from 2005-2010.

The 4.7-litre HO engine was popular for its durability and reliability. But like any engine, regular maintenance is important to keep it running smoothly.

Otherwise, some issues may arise including oil consumption, Crankshaft sensor failure, oil leak, poor spark, noise etc.

In this article, we’ll discuss the most common Jeep 4.7 Ho engine problems and solutions.

Jeep 4.7 Ho Engine Overview

The 4.7L PowerTech has a cast-iron cylinder block with a bore spacing of 4.09 inches (104 mm), a deck height of 9.09 inches (231 mm), and an angle of 90 degrees between the cylinder banks, making it ideal for using one crankpin journal for two connecting rods. All dimensions of the engine block have been redesigned from scratch.

In the debut engine, a nodular cast-iron crankshaft was mounted on the block instead of five individual main bearing caps using a single bedplate. Vibration and noise are reduced by the compacted graphite iron bedplate.

The connecting rods are fracture-split and made of powder-forged metal. The pistons are cast aluminum with moly coated skirts. A stamped steel oil pan seals the crankcase from underneath. A balancing shaft is needed for the 3.7L V6, but not for the 4.7L.

How Good Is the Jeep 4.7 Engine?

It features a cast-iron cylinder block with a bore spacing of 4.09 inches (104 mm), as well as a deck height of 9.09 inches (231 mm) and a 90-degree angle. A new engine block was created for this engine based on all dimensions being new. “High-Output” versions of Chrysler’s 4.7L PowerTech engine were introduced in 2002.

In addition to standard Jeep Grand Cherokee Overland models, this version was used in several Jeep Grand Cherokee Limited vehicles. Also included are two knock sensors, new camshafts, high-compression domed pistons, and a tuned intake on the 4.7L V8 High Output engine. The 5.7L V8 Hemi engine was then replaced with a high output version with 30 horsepower and 35 lb-ft of torque. There were some minor changes to the standard version in 2005, including two knock sensors. A huge change was made to the 4.7L PowerTech engine in 2008.

For the 2008 model year, PowerTech’s 4.7L V8 engine featured two spark plugs per cylinder and all-new cylinder heads. A brand-new and lightweight piston and forged steel combination were installed at the bottom of the engine. Furthermore, the compression ratio was increased from 9.0:1 to 9.8:1.

How Much Horsepower Does A 4.7 Liter V8 Engine Have?

The Ram has a 4.7-liter V8 engine that offers 310 horsepower and 330 pounds-feet of torque, which serves as the middle engine. Despite its impressive power, this engine’s poor gas mileage leads many to recommend the 5.7-liter Hemi V8, which delivers 390 horsepower and 407 pounds-feet of torque.

Most Common Jeep 4.7 Ho Engine Problems & Solutions!

The most common problems associated with the 4.7-litre HO (High Output) engine in the Jeep Grand Cherokee include:

- Timing chain issues

- Oil consumption

- Head gasket failure

- Crankshaft sensor failure

- Throttle body issues

- Fuel Injector Failure

1. Timing chain issues

The timing chain is a crucial component of the engine that synchronizes the movement of the camshaft and crankshaft. It is responsible for ensuring that the engine’s valves open and close at the correct time. In the 4.7-liter HO engine, the timing chain can stretch and wear out over time.

When this happens, it can cause the following problems:

- Engine misfire: If the timing chain stretches too far, it can cause the valves to open and close at the wrong time, leading to engine misfires and poor performance.

- Engine noise: A stretched timing chain can cause a rattling or ticking noise from the engine, indicating that the timing chain is loose.

- Reduced engine power: A stretched timing chain can cause the engine to lose power, as the valves are not opening and closing at the correct time.

- Engine damage: If the timing chain breaks, the engine’s valves can collide with the pistons, causing severe engine damage.

How To Solve This Issue

The best way to solve timing chain issues in a 4.7-liter HO engine is to have the timing chain and related components inspected and replaced as needed by a professional mechanic. The following are some steps that can help solve timing chain issues:

- Regular Maintenance: Keep up with regular maintenance and inspections as recommended by the vehicle’s manufacturer to ensure that the timing chain is in good condition.

- Listen for unusual noises: If you hear a rattling or ticking noise from the engine, it could be an indication of a stretched timing chain and it’s best to have it checked by a professional.

- Check for engine misfires: If the engine is misfiring, it could be an indication of a stretched timing chain, and it’s best to have it checked by a professional.

- Replace the timing chain and related components: If the timing chain is stretched or damaged, it will need to be replaced along with other components such as the tensioner and guides.

- Timing chain tensioner replacement: If the tensioner of the timing chain is the root cause of the problem, replace it.

2. Oil Consumptions

Oil consumption in the 4.7-liter HO engine can cause several problems:

- Reduced engine performance: If the engine is low on oil, it can lead to a decrease in performance and power.

- Engine damage: If the engine runs low on oil, it can cause damage to the internal components such as the pistons, bearings, and crankshaft.

- High oil consumption: Excessive oil consumption is a sign of an internal problem, such as worn piston rings, which can lead to poor engine compression and oil leaks.

- Warning light illumination: If the oil level is low, it can trigger the oil pressure warning light on the dashboard, indicating that the engine is low on oil and you need to check it.

- Decreased fuel efficiency: Oil consumption can lead to poor fuel efficiency as the engine has to work harder to compensate for the lack of lubrication.

How To Solve This Issue

To solve this issue, the mechanic must identify the precise cause of the problem before replacing any worn-out or damaged components. An engine overhaul may be required in specific circumstances. It’s crucial to have a reliable mechanic identify the issue, then adhere to the suggested service intervals from the manufacturer and apply the right type and weight of oil.

In addition, it’s also a good practice to regularly check the oil level and top it off as needed to ensure that the engine is running with the correct amount of oil at all times. This will help prevent damage to the engine and prolong its lifespan.

3. Head Gasket Failure

A head gasket failure in a 4.7-liter HO engine can cause several problems, including:

- Coolant leaks: If the head gasket fails, coolant can leak into the combustion chamber, which can cause a loss of coolant, overheating and damage to the engine.

- Oil leaks: A blown head gasket can leak oil into the combustion chamber and coolant passages, causing an engine to lose oil pressure and die. Read More Why Is My Jeep Wrangler Leaking Oil? Reasons Explained!

- Compression loss: A leaking head gasket causes the combustion chamber gasses to leak out, which reduces engine power and causes a loss of compression.

- Mixing of oil and coolant: If the head gasket fails and oil and coolant mix together, it can lead to sludge and clogging of passages, causing damage to the engine.

- Overheating: A head gasket failure can cause coolant to mix with the oil, which can cause a reduction in the engine’s cooling ability, leading to overheating.

How To Solve It

To solve a head gasket failure in a 4.7-liter HO engine, a mechanic should diagnose the issue through a compression test, a leak-down test, and a visual inspection of the engine. Replace the head gasket to fix the problem. It’s important to address head gasket failure as soon as possible to prevent damage to the engine.

4. Crankshaft Sensor Failure

A crankshaft sensor failure in a 4.7-liter HO engine can cause several problems, including:

- Difficulty starting: The crankshaft sensor is responsible for sending information about the engine’s speed and position to the engine control module (ECM). If the sensor fails, the ECM may not receive the correct information and may not be able to start the engine.

- Stalling or misfiring: If the crankshaft sensor fails, the engine may stall or misfire, as the ECM may not be able to receive the correct information about the engine’s speed and position.

- Poor fuel economy: A faulty crankshaft sensor can cause the engine to run rich or lean, which can result in poor fuel economy.

- Check engine light: In many cases, a crankshaft sensor failure will trigger the check engine light to come on, which will alert the driver that there is a problem with the engine.

How To Solve It

To solve a crankshaft sensor failure in a 4.7-liter HO engine, a mechanic should diagnose the issue by using a diagnostic tool to check the sensor’s signal and comparing it to the factory specifications.

If the sensor seems faulty, replace it to fix the problem. In some cases, it can happen because of other issues, such as wiring or connector problems. These issues should be inspected and repaired if necessary.

4. Throttle Body Issues

Throttle body issues can cause problems in a 4.7-liter HO engine by affecting the airflow into the engine. Some possible symptoms of a throttle body issue include:

- Reduced engine power: If the throttle body is dirty or clogged, it can restrict the airflow into the engine, which can reduce engine power.

- Stalling: If the throttle body is sticking or not functioning well, it can cause the engine to stall, especially when coming to a stop or idling.

- Unusual engine noises: If the throttle body is dirty or clogged, it can cause unusual engine noises such as whistling or sucking sounds.

- Check engine light: A malfunctioning throttle body can cause the check engine light to come on as it will impact the engine performance.

- Reduced fuel economy: A dirty or clogged throttle body can cause the engine to run rich, which can reduce fuel economy.

How To Solve It

By completing a visual inspection of the throttle body and looking for indications of dirt, debris, or damage, a mechanic can identify throttle body problems. They can also check the sensor’s signal using a diagnostic instrument and compare it to the factory specs.

The throttle body should be cleaned. But if you find it dirty or clogged with debris, replace it.

5. Fuel injector failure in a 4.7-liter HO engine can cause several problems, including:

- Reduced engine power: If one or more fuel injectors are clogged or not functioning well, it can affect the engine’s ability to receive the correct amount of fuel. Which can reduce engine power.

- Rough idling: If one or more fuel injectors are clogged or not functioning well, it can cause the engine to idle roughly or stall.

- Poor fuel economy: It can cause the engine to run rich or lean, which can reduce fuel economy.

- Engine misfires: It can cause the engine to misfire or hesitate while accelerating.

- Check engine light: A malfunctioning fuel injector can cause the check engine light to come on as it will affect the engine performance.

How To Solve It

A mechanic can diagnose fuel injector failure by performing a visual inspection of the fuel injectors, looking for signs of leakage or damage.

How Much Reliable is the Jeep 4.7 V8 Ho Engine?

Regular maintenance can easily extend the life of this engine to 200,000 miles (300,000 km). It is important to keep in mind that the PowerTech engine family does not tolerate poor maintenance. Otherwise, the engine becomes very dirty from the inside, leading to more serious problems. Thin oils and short intervals between oil changes are required for the engine.

Maintenance Tips for Jeep 4.7 Ho Engine Problems

Here are a few tips to help you deal with the most common Jeep 4.7 engine problem.

- Before using a vehicle in a low-temperature area, heat it for at least 15 minutes.

- Ensure that the engine is free from cracks and damages by thoroughly inspecting it.

- Oil filters should be changed periodically.

- It is important to use high-quality oil and fuel

- A minimum of once a year, perform the required maintenance.

- Make sure that the cooling system is functioning properly.

- Engine components that are damaged should be replaced.

- If your engine is performing irregularly, don’t be late to take action.

- Saving money by following these tips will benefit you in the long run. As a result, periodic maintenance ensures a smooth and comfortable ride.

Final Thought

The 4.7-liter HO engine found in certain Jeep models is known for its power and durability. However, it may encounter problems such as oil consumption, head gasket failure, crankshaft sensor failure, throttle body issues, and fuel injector failure.

These issues can happen because of a variety of factors such as wear and tear, poor maintenance, or manufacturing defects. To prevent additional engine damage and keep the vehicle running smoothly, it’s important to address these issues as soon as possible.

Keep Reading Most Common Jeep 3.8 Engine Problems: Explained

FAQs

How reliable is the 4.7 HO engine?

The 4.7L’s reliability is generally mediocre. These engines won’t likely endure for 300,000+ miles, in my opinion. Nevertheless, there are many millions of them on the road, and they are quite simple to repair. & you can solve them at a reasonable cost.

Which cars were included with the 4.7 HO?

- 2002–2004 Grand Cherokee Jeep.

- Jeep Grand Cherokee, years 2007–2008.

- Dodge Dakota, models 2007–2008.

- Ram 1500 from 2007 to 2008.

What kind of power can the Jeep Grand Cherokee 4.7 produce?

The 4.7 L was improved, and it now generates 305 horsepower (227 kW; 309 PS) and 334 pound-feet (453 Nm). An upgraded 5.7 L Hemi engine with 360 horsepower (268 kW; 365 PS) and 390 lb-ft (529 Nm) of torque was offered for the 2009 Jeep Grand Cherokee.

Certify that the charm of a pre-owned supercar like the Audi R8 also exists. Even a well-known brand like Ferrari has some pre-owned treasures that collectors need to pay more attention to due to badging or looks. One particular model was always (relatively) reasonable: the Hot Wheels Ferrari 360. You can uncover some incredible high-end automotive deals on the used market if you search carefully enough.

A 3.6-liter V8 engine powered the car. It came with the option of a 6-speed manual or a 6-speed F1 automated manual transmission. Handling and performance made the 360 well-regarded, boasting a top speed of 186 mph and a 0-60 time of 4.5 seconds.

The Hot Wheels Ferrari 360 was also notable for its advanced technology. Also has an aluminum space frame chassis and distinctive styling. The design of the Ferrari F50 influences it. Critics praised the high-quality materials and craftsmanship of the 360’s interior.

Hot Wheels Ferrari 360 Models

The Ferrari 360 was available in two models:

- the 360 Modena

- the 360 Spider.

First, they introduced the Modena coupe, then the Spider convertible. A 3.6-liter V8 engine with 400 horsepower and 275 lb-ft of torque powered both variants. The 360 was popular for its handling and performance.

It was also praised for its design, a departure from the more rounded look of previous Ferraris. Ferrari introduced the first electronic stability control system in the 360. It remains one of Ferrari’s most popular models and is considered a classic today.

Are Ferrari 360 Affordable or Not?

The Hot Wheels Ferrari 360 is a supercar famous for its sleek design, powerful performance, and exclusivity. But, what many people may not know is that the 360 is also surprisingly affordable. When compared to other supercars on the market.

When it was new, the base price for the Ferrari 360 started at around $189,000 USD. Now the price of a used Hot Wheels Ferrari 360 varies depending on the model, the condition, the mileage, and the location. But the price could be more than $100,000.

Of course, owning a Ferrari also comes with extra costs, such as maintenance, repairs, and insurance, which can be pretty high. But after all, the Hot Wheels Ferrari 360 is a supercar. Offers a great balance of performance that is exclusive and affordable for the customer who uses a supercar daily.

Ferrari 360 specs

| Engine | 3.6 Litre V8 |

| Power | 400 HP |

| Torque | 275lb-ft |

| Transmission | 6-speed manual or 6-speed F1 paddle shift |

| Top Speed | 183 mph (Modena) / 181 mph (Spider) |

| Curb Weight | 3,042 lbs (Modena) / 3,197 lbs (Spider) |

The Hot Wheels Ferrari 360 was well-received by critics and remains highly sought after by car enthusiasts.

Key Features Of Ferrari Hot Wheels

One of the most notable sports cars of its era. The Ferrari 360 is fit for several features. That made it stand out from the competition.

Aluminum spaceframe

Lightning the vehicle and boost performance. The 360’s lightweight aluminum chassis and bodywork helped.

Electronic stability control

One of the first Ferraris to feature electronic stability control. The 360 improved handling and safety.

Paddle shift transmission a la F1

They offered the 360 with a 6-speed paddle shift transmission similar to F1’s. That permitted incredibly quick gear changes and raised the level of excitement in the driving experience.

Magnaride suspension

A semi-active suspension system known as Magnaride equipped the 360. They used magnetorheological dampers to adjust the suspension in real-time depending on driving conditions and style.

Carbon-ceramic brakes

Compared to conventional iron brakes, the 360 was offered with optional carbon-ceramic brakes, which provided better stopping power and fade resistance.

Engine

3.6-liter V8 engine with 275 lb-ft of torque and 400 horsepower.

Design

A low and wide stance, a long hood, and a short rear deck characterized the 360. It was renowned for its sleek and contemporary styling.

The Hot Wheels Ferrari 360 was also equipped with various luxury features, including leather seats, a premium sound system, and a navigation system.

Things To Know Before Buying A Ferrari

When considering purchasing a Ferrari 360, there are several things to keep in mind:

1. Condition of the vehicle

Ensure to thoroughly inspect the vehicle for any signs of wear and tear, and have a trusted mechanic check for potential mechanical issues.

2. Service History

Be sure to do proper vehicle maintenance by researching its service history.

3. Mileage

Take the car’s after-all mileage into account. It affects the vehicle’s performance and lifespan. If the car has been modified, make sure you know the changes and how they might have impacted its performance.

4. Insurance

Verify that you can afford the cost of insuring the vehicle by looking up the insurance rates for it.

5. Cost of maintenance

Ferraris are known for having high maintenance costs, so be sure you can afford them.

6. Resale value

To understand how the Hot Wheels Ferrari 360s will fare in the future. You have to look into how well they have done historically regarding resale value.

What is it like to drive and own a Ferrari 360?

Drivers find the Hot Wheels Ferrari 360 thrilling and interesting to drive. A potent V8 engine, advanced suspension, and braking systems equip the 360. It enables to delivery of impressive performance and handling. The car is responsive and agile on the road, thanks partly to its lightweight aluminum bodywork and chassis.

Moreover, owning a Hot Wheels Ferrari 360 can be a rewarding experience for car enthusiasts. The car’s exclusivity and iconic status make it a head-turner. Also, its performance capabilities offer a thrilling driving experience.

But owning a Ferrari comes with certain costs and considerations. The car requires regular maintenance and servicing, which can be costly. And, like any exotic car, the 360 may depreciate over time.

Learn More From Here:

Furthermore, the car’s high performance demands a skilled driver. It’s not suitable for everyday commutes. Also, the exclusive brand leads to expensive parts and services.

Maintenance Guide For Ferrari 360

Maintaining Hot Wheels, Ferrari 360 requires regular service and attention. To keep the 360 running at its best, remember these important maintenance items:

1. Oil changes

The 360’s V8 engine requires regular oil changes. Typically, every 7,500 miles or six months, whichever comes first.

2. Timing belt replacement

Replace the 360’s timing belt. Whichever occurs first: every four years or 40,000 miles. Severe engine damage can result from a failed timing belt, making it crucial to keep up with this service.

3. Brake pads and rotors

The 360’s high-performance braking system requires regular brake pads and rotors replacement. Expect replacing the pads every 15,000 miles and the rotors every 30,000 miles.

4. Suspension and alignment

The 360’s advanced suspension system should be inspected and serviced regularly. Periodically check the alignment to make sure it’s in good working order. Ensure the car tracks straight and true.

5. Air filter

The 360’s air filter should be replaced every 15,000 miles. By doing so, you can ensure that the engine gets a sufficient supply of clean air.

6. Battery

Check the battery regularly. To ensure that it is holding a charge and is in good condition.

7. Tires

You should check The 360’s high-performance tires for wear and replacement when necessary.

8. Cleaning

The car should be cleaned regularly. Especially in the undercarriage to avoid corrosion.

Keep a record of all services performed on the car and have it serviced by a reputable Ferrari-trained technician. The car benefits from preventive maintenance, keeping it running smoothly and reducing the risk of expensive repairs in the future.

Conclusion

After all, the Hot Wheels Ferrari 360 is a highly desirable car for car enthusiasts. But it’s important to remember the costs and responsibilities of owning such a vehicle.

Moreover, the Hot Wheels Ferrari 360 is a surprisingly affordable everyday supercar. The Ferrari 360 offers a great balance of performance, exclusivity, and affordability. It makes it a great choice for daily use by car enthusiasts. Also, it’s an opportunity to own one of the world’s most iconic car brands without a high cost.

Keep Reading How Long Do FJ Cruisers Last? Get The Facts Here!

FAQ

The Hot Wheels Ferrari 360 is sized at what ratio?

The Hot Wheels Ferrari 360 is typically produced in 1:64 scale models.

When did the Hot Wheels Ferrari 360 hit the shelves?

They produced the Hot Wheels Ferrari 360 in several series between 2000 and 2010.

Do you have the Hot Wheels Ferrari 360 in a variety of colors?

They have made the Hot Wheels Ferrari 360 available in a variety of colors, including red, yellow, silver, and black.

Do Hot Wheels Ferrari 360s still have any stock?

The future is uncertain because Hot Wheels retires some older models and releases new ones every year. Confirm availability by contacting the manufacturer, the best way to do so.

How come the Ferrari 360 Modena is so affordable?

The Ferrari 360’s low price is primarily due to depreciation because consumers aren’t currently willing to pay more for it than for other models. The number of units sold overall is one of the underlying factors influencing market prices.

The 2023 Jeep Grand Cherokee is a versatile and stylish SUV that is famous for its impressive capabilities. One of its standout features is the Quadra-Lift air-ride suspension, which has been a part of the Grand Cherokee line-up since 2010. It can ground clearance, wheel movement, and height, providing unparalleled adaptability while driving. At first, this technology was only available for certain models of the Grand Cherokee WK, but now it is more widely available. However Jeep Grand Cherokee Air Suspension Problems are commonly reported by users.

The air suspension in a Jeep Grand Cherokee is designed to offer a comfortable and smooth ride for the driver and passengers. However, over time, some users may encounter problems with the air suspension. To address these issues, it is important to identify the problem and understand potential solutions. This article will provide information on common problems associated with air suspension, as well as methods for troubleshooting and resolving these issues.

What is Air Suspension?

A regular suspension system works similarly to an air suspension system. For a stable, comfortable driving experience, both types of suspension connect a vehicle’s body to its wheels/brakes and absorb road bumps/vibrations.

The air suspension, however, uses rubber bags filled with air instead of coil springs made of steel. There are also air compressors (for supplying air), height sensors and pressure sensors, and air reservoirs (for storing air).

The control module monitors the air pressure of each air spring. A low pressure will increase the height of the air spring by blowing air into it.

A high pressure, however, releases more air from the air spring. As The suspension system offers many advantages over spring-based suspension systems, including a comfortable ride (even on rough surfaces), improved handling, and long-lasting performance.

What does the Air Suspension Do?

There are several important functions that your Jeep’s suspension performs while you’re driving.

Firstly, your suspension connects the wheels to your vehicle’s body. As opposed to being rigidly attached to the vehicle, your suspension system allows the wheels to move freely. It is the wheels, not the body, that adjust when you hit a bump, for example.

In addition to increasing stability and comfort, your suspension also improves handling. In addition to absorbing vibrations, suspension keeps your vehicle stable while turning, resulting in a more comfortable drive.

Adding air suspension to your Jeep Grand Cherokee is possible with Quadra-Lift. The suspension can be raised or lowered automatically, without having to stop the vehicle. Users of Jeeps will benefit from this in terms of utility. As long as the system does not fail and you can get it repaired before it leaves you in park. The lack of Quadra-Lift suspension on the new Grand Cherokee L models might have something to do with this.

There are, however, some early warning signs of air suspension failure with your Jeep Grand Cherokee. It is important to keep an eye out for these signs in order to avoid driving on a faulty suspension, which can cost you time and money.

How Long Will The Air Suspension Last In My Jeep Grand Cherokee?

The Jeep Grand Cherokee is famous for its longevity, with many models lasting well over 250,000 miles. The air suspension system in this vehicle is reliable, with a lifespan of approximately 100,000 miles or more. But, at around 120,000 miles, it is common for Grand Cherokee owners who have the air suspension option to need to replace all four air springs.

But like any vehicle, it can experience problems. One issue that some Jeep Grand Cherokee owners may encounter is a problem with the air suspension system. If you are experiencing this issue.

What are the Possible Signs Air Suspension Problems?

Here are some possible signs of Jeep Grand Cherokee air suspension problems:

- Uneven tire wear: If your Jeep’s suspension is poor, this may result in your tires wearing more on one side than the other. This may result in ineffective handling and decreased fuel efficiency.

- Poor handling: If your Jeep’s suspension is malfunctioning, it may affect how the car handles. When driving, you might feel your Jeep is unstable or “bouncy,” or that it is challenging to steer or control.

- Increased body roll: When a vehicle is turning, it has a tendency to lean or tilt to one side. Increased body roll, which can make the Jeep feel less stable and more prone to toppling over, can be a sign that your Jeep’s suspension isn’t working well.

- Poor suspension: When driving over bumps or other rough surfaces, your Jeep may make knocking or clunking noises. The suspension system’s worn-out shock absorbers or damaged ball joints may be the root of this problem.

- Fluid leaking: If you notice fluid dripping from the suspension system of your Jeep, there might be an issue with the system. There are many different problems that can lead to fluid leaks, such as worn or damaged seals or broken hydraulic parts. Read more about Why Is My Jeep Wrangler Leaking Oil? Reasons Explained!

What Are The Jeep Grand Cherokee Air Suspension Problems?

The system of a traditional metal-spring suspension is different from the air suspension system. Four air springs, a compressor, some pressure-holding lines, and electronic control blocks will be used for operating all these components.

You won’t believe it, but all units of the air suspension system in your Grand Cherokee will fail. Not the springs could begin to leak air or something. It’s about all parts of the system.

The most typical issues are listed below:

- leaking air – the air spring may experience air leaks as a result of some of the rubber components drying out and becoming unable to maintain the required pressure;

- leaky lines: the compressor will begin running continuously because of the pressure these lines are releasing;

- compressor issues – it could stop working, causing your vehicle to after all drop to the lowest clearance possible;

- impossible stiffness – the vehicle will be stiff and impossible to drive as a result of suspension issues;

If the electronic control units begin malfunctioning as well, the tension will start to fluctuate in numerous ways.

The fact that each component of the suspension depends on the others is the most unpleasant aspect. The compressor will have to work harder to maintain the required pressure. After all, it will impact all other air springs and worsen wear and tear on the compressor.

Is it Possible to Drive with Jeep Grand Cherokee Air Suspension Problems?

It is not recommended to drive a vehicle with a bad suspension. A faulty suspension system can affect the handling and stability of the vehicle, which can be dangerous when driving. It can also cause additional wear and damage to other components of the vehicle, such as the tires, brakes, and steering system. If you notice any of the signs that your Jeep’s suspension is bad, it is important to have it repaired as soon as possible to avoid further damage.

Solutions

- Leaking air suspension system: If the air suspension system is leaking, it will not be able to hold the proper amount of air pressure and will not function well. This can be caused by a faulty air spring, airline, or compressor. To fix this problem, the faulty part will need to be repaired or replaced.

- Compressor malfunction: The compressor is in charge of supplying the air suspension system with air. The air suspension won’t work if the compressor is malfunctioning. An unreliable compressor or a wiring issue may be to blame for this. The compressor will need to be fixed or replaced to solve this issue.

- Misaligned height sensor: The vehicle’s height is measured by the height sensor, which then modifies the air suspension as necessary. If the height sensor is broken, the air suspension won’t function well. The malfunctioning height sensor can be changed to resolve this.

Troubleshooting Jeep Grand Cherokee Air Suspension

Troubleshooting your Grand Cherokee’s air suspension is quite important, as you may know. Professionals typically perform this task, but if you want to do it yourself, you can follow two methods.

The first method involves scanning the fault code on the dashboard with an OBDII scanner and identifying the root cause. Otherwise, check the air springs and all the lines supplying air visually. Any leaks should be detected by inspecting the compressor and other components.

To do this, spray a three-percent solution of wet vacuum soap onto each connector and every pipe joint. The origin of your problem might be found by identifying a bubble where a leak is also present.

It would then be necessary to either replace the tube or repair the punctured part. Below the hood is a fuse that provides 40 amps of power. The compressor is likely to have seized or stopped working when this fuse blows.